Gear control method and system for automatic gearbox of loader

A technology of automatic shifting and control method, which is applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problems of repeated up-down and down-shift, achieve the effect of stable gear position and solve the problem of repeated up-down and down-shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

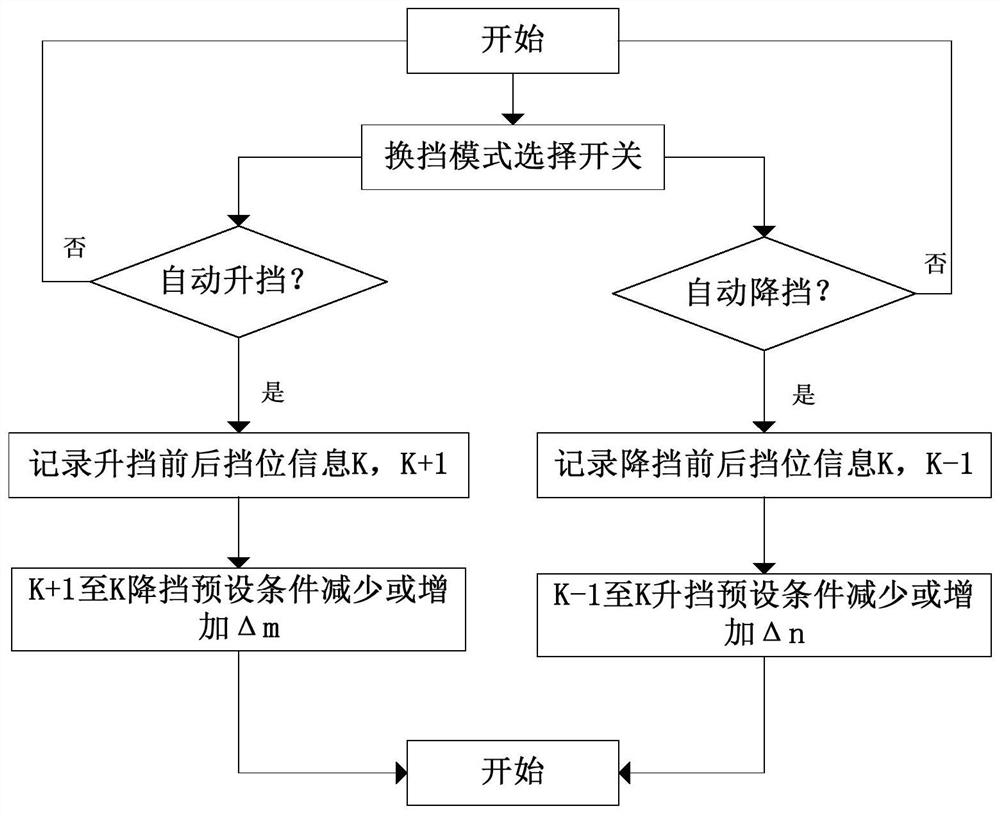

[0036] Such as figure 1 As shown, a loader automatic transmission gear control method, including:

[0037] When the loader is in the climbing condition and the shift mode switch is selected as the automatic shift mode, obtain the gear change information of the gearbox;

[0038] In response to meeting the preset condition N in the upshift strategy table Kup , the gearbox is upshifted, the gearbox is upshifted from the current gear K to K+1 gear, the gear information of the K gear before the upshift and the K+1 gear after the upshift is recorded, and an instruction is issued to control the downshift strategy table The preset condition N of the original downshift from K+1 to K K+1Down Increase or decrease Δm, adjust to N K+1Down +Δm or N K+1Down -Δm, making it more difficult to downshift from K+1 to K;

[0039] Or, in response to meeting the preset condition N in the downshift strategy table KDown , the gearbox is downshifted, the gearbox is downshifted from the current gea...

Embodiment 2

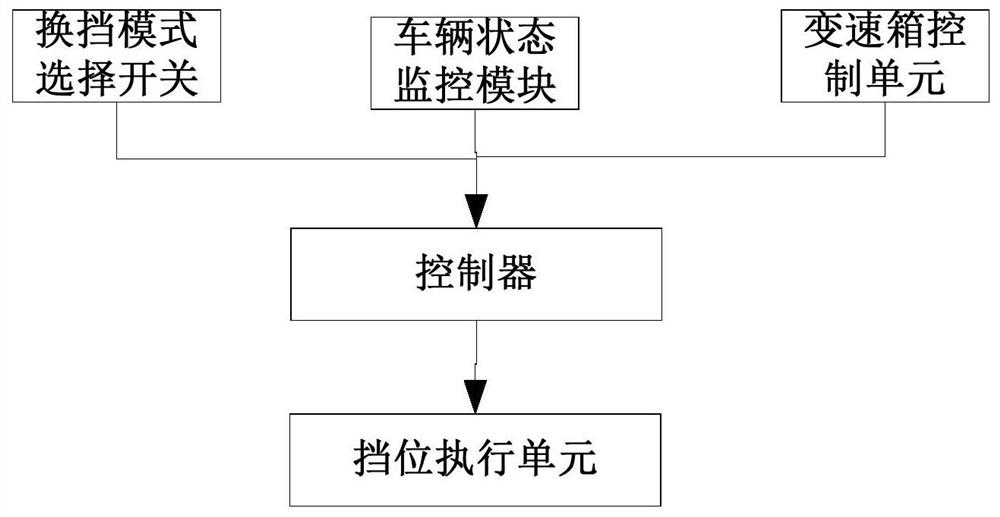

[0058] Such as figure 2 As shown, a loader automatic transmission gear control system includes a controller, the controller includes a memory and a processor, the memory is used to store instructions, and the instructions are used to control the processor to operate to execute The above-mentioned gear control method of the automatic transmission of the loader.

[0059] In some embodiments, the memory also stores a shift strategy table, including a downshift strategy table and an upshift strategy table.

[0060] In some embodiments, the gear control system of the loader automatic transmission further includes: a transmission control unit, a shift mode switch, a vehicle state monitoring module, a gear execution unit; a transmission control unit, a shift mode The switch, the vehicle status monitoring module, and the gear execution unit are all connected to the controller,

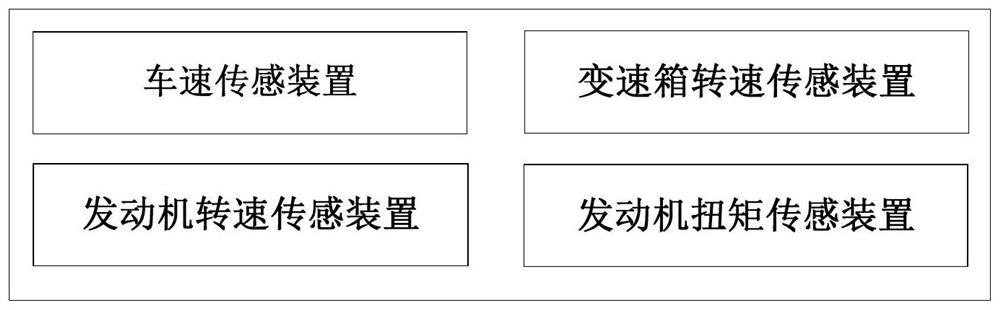

[0061] The gearbox control unit is used to collect the operation signal of the whole machine and the sig...

Embodiment 3

[0063] A loader, comprising the above-mentioned gear control system of the automatic transmission of the loader.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com