A liquid chlorine packaging integrated device

A technology of liquid chlorine and bottom platform, which is applied in the direction of gas/liquid distribution and storage, equipment loaded into pressure vessels, container filling methods, etc., which can solve the problems of occupation, cumbersome, large production space, etc., to reduce space requirements and improve Work efficiency, the effect of reducing labor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

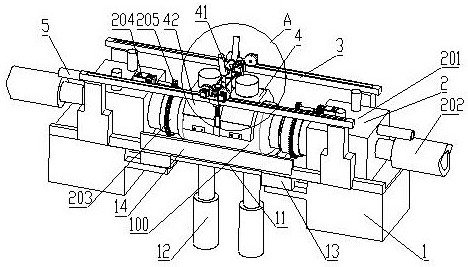

[0040] see figure 1 and figure 2 , the present invention provides an integrated device for liquid chlorine packaging, comprising a bottom platform 1 arranged on the ground, a space for placing a liquid chlorine bottle 100 is reserved in the middle of the bottom platform 1, sliding platforms are arranged on both sides of the bottom platform 1, and sliding platforms on each side A clamping mechanism 2 is arranged on the table, and the clamping mechanism 2 includes a clamping electromagnet 201 that is slidably connected with the slide table. One end to the outside of the electromagnet housing is oppositely arranged, and the end of the clamping electromagnet 201 facing the outside of the base 1 is provided with a main push rod 202, and the movable end of the main push rod 202 is fixedly connected with the housing of the clamping electromagnet 201, and the main push Rod 202 can be selected from electric, pneumatic or hydraulic push rods;

[0041] The magnetic end of the electrom...

Embodiment 2

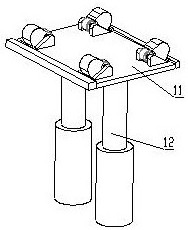

[0063] see image 3 , on the basis of Embodiment 1, an open channel is set in the middle of the bottom platform 1, a lifting plate 11 is set on the lower side of the channel, the lower side of the lifting plate 11 is fixedly connected to the lifting rod 12, and the upper side of the lifting plate 11 is provided with a 100 for supporting the liquid chlorine bottle. The support frame rotates and connects the rollers on the support frame. When the liquid chlorine bottle 100 is placed on the support frame, the rollers stick to the bottle body of the liquid chlorine bottle 100, and the liquid chlorine bottle 100 does not contact the upper side of the lifting plate 11.

[0064] Through this structure, the switching of the liquid chlorine bottle 100 is realized. The lifting rod 12 is installed under the ground surface, and the lifting rod 12 is lowered to place the lifting plate 11 slightly lower than the ground surface, so that the liquid chlorine bottle 100 to be filled can be rolle...

Embodiment 3

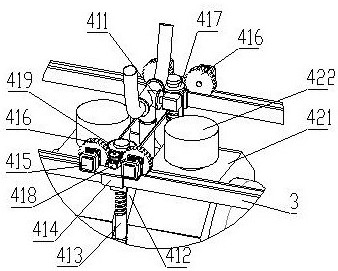

[0066] On the basis of the above-mentioned embodiments, connecting rods 413 are symmetrically fixed at both ends of the outer wall of the arc-shaped surface of the injection shell 412, and the connecting rods 413 extend vertically upwards to connect with the slider 414, and the slider 414 is slidably connected to the track 3;

[0067] The slider 414 is provided with a moving motor 415 for driving the slider 414 to move along the track 3 , the motor shaft of the moving motor 415 is linked with the track wheel 416 , and the track wheel 416 moves along the track 3 .

[0068] Through this mechanism, the cleaning mechanism 4 can be moved along the track 3, thereby reducing the volume of the cover 421. Through the reciprocating sliding of the cleaning mechanism 4, the cleaning and magnetic powder liquid covering on the outside of the liquid chlorine bottle 100 can be realized. The relatively small volume of the cover 421 is easier to maintain, and the consumption of magnetic powder l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com