Special clutch disc assembly vibration reduction torsion running-in device for engineering dump truck

A technology for clutch discs and dump trucks, which is applied in the testing of instruments, machine/structural components, mechanical components, etc., and can solve problems such as lack of disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

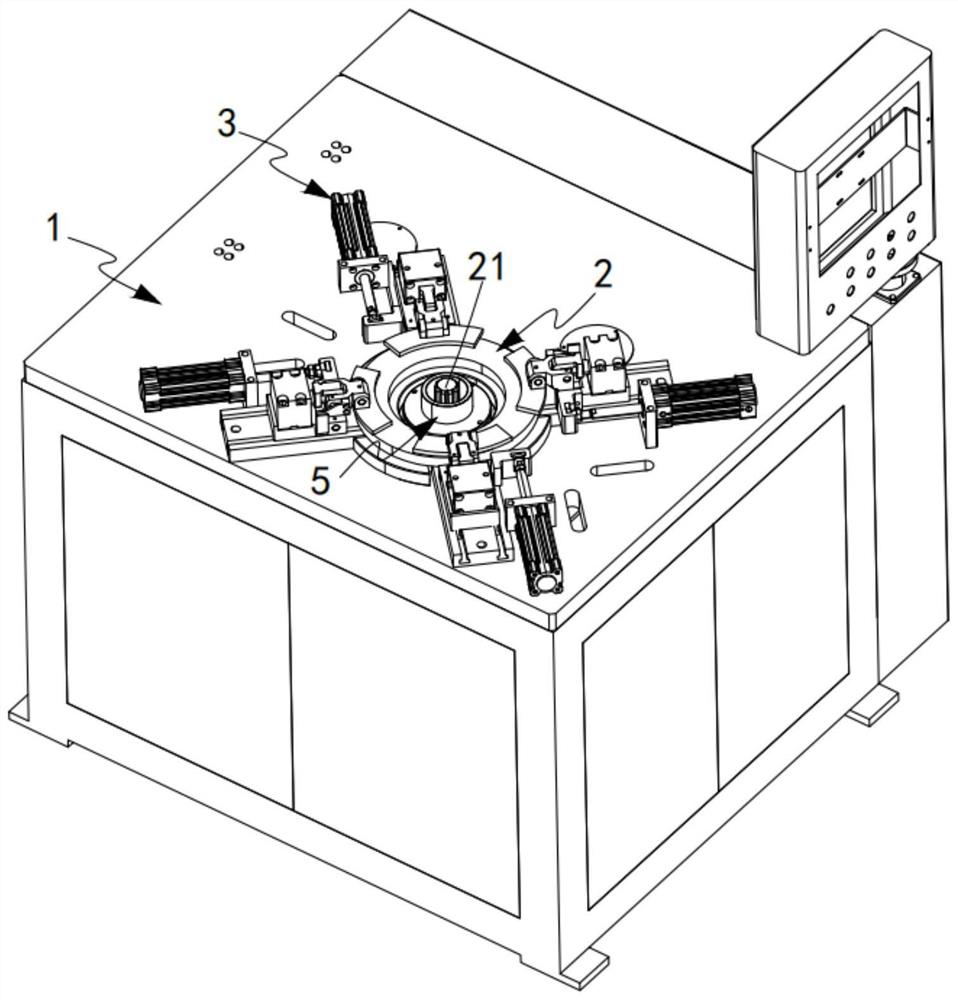

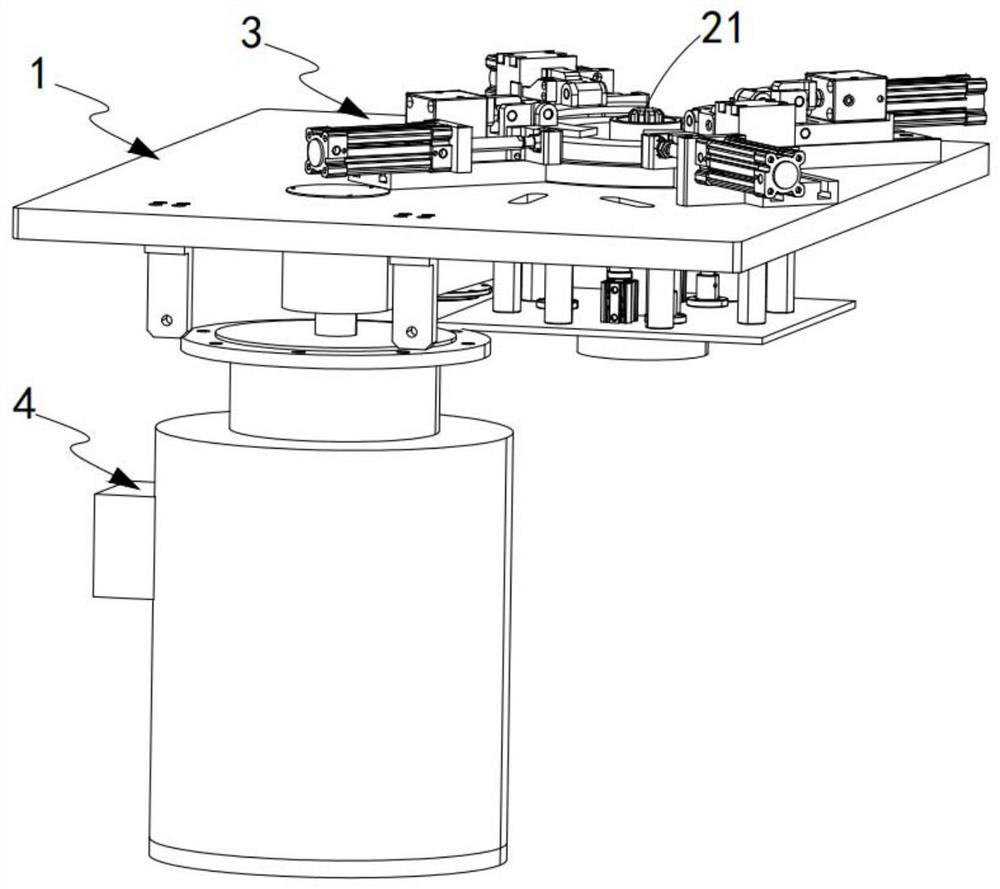

[0067] Such as Figure 1 to Figure 12 As shown, a vibration-damping and torsional running-in equipment for a clutch disc assembly dedicated to an engineering dump truck includes an installation platform 1 and also includes:

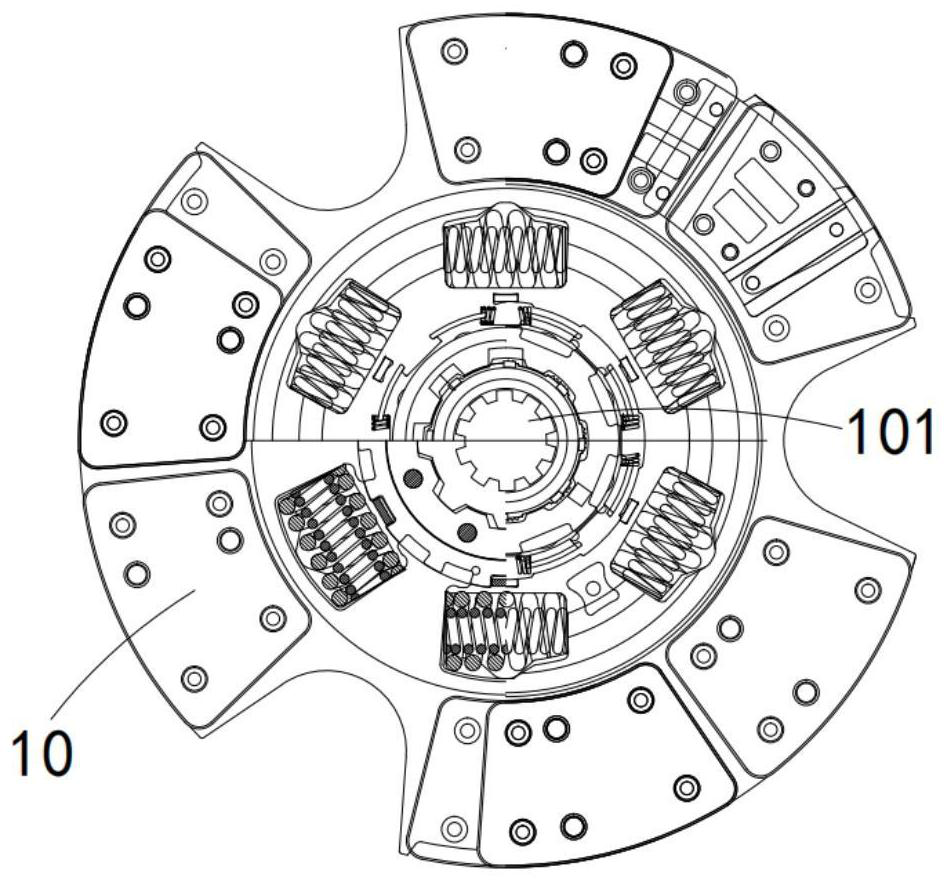

[0068] The loading tray 2, the loading tray 2 is installed on the installation platform 1, it is arranged in a ring shape, and it is used to carry the clutch disc assembly 10, the center position of the loading tray 2 is provided with a clutch The spline shaft 21 where the inner disc hubs 101 on the disc assembly 10 are inserted into each other;

[0069] Positioning and pressing mechanism 3, several groups of said positioning and pressing mechanisms 3 are equidistantly arranged around said loading tray 2 around said loading tray 2, said positioning and pressing mechanism 3 includes a sliding flip assembly 31 and a pressing assembly 32, the pressing assembly 32 is driven by the sliding and turning assembly 31, and while sliding in the radial direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com