Manufacturing method of automobile roller shutter door

A manufacturing method and technology for rolling shutter doors, which can be applied to household components, household appliances, other household appliances, etc., can solve the problems of easy cracking of film sheets, difficulty in mold manufacturing, and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

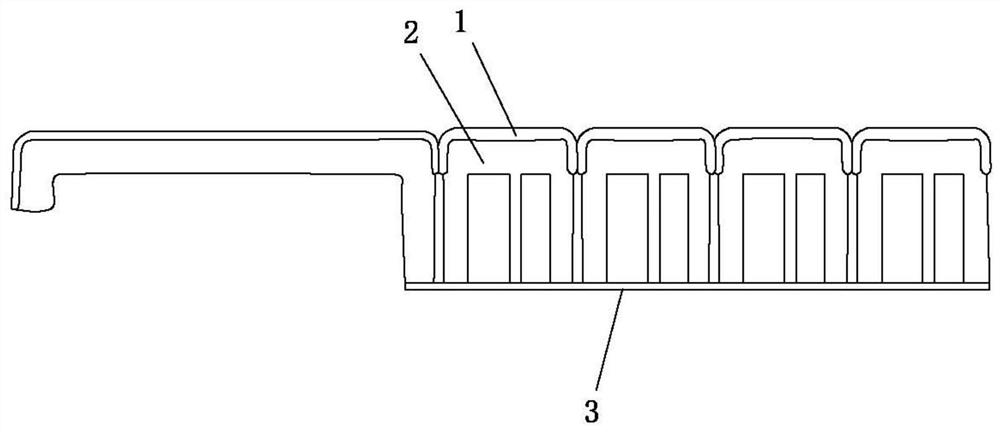

[0025] Such as figure 1 Shown, a kind of automobile rolling door manufacturing method provided by the present invention, it comprises the steps:

[0026] Step (1): A single film piece 1 is injection-molded through the first injection mold, or a piece of film is injection-molded through the first injection mold, and then the film is cut according to the required specifications by a cutting mechanism cut to form a single adhesive film piece 1;

[0027] Step (2): heating single or multiple film pieces 1 to soften the film pieces 1;

[0028] Step (3): Blister and shape the softened film piece 1 through the blister forming method, so that the film piece 1 is formed into the desired shape, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com