Multi-spectrum composite camouflage material and preparation method thereof

A multi-spectrum, mixed coating technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of difficult construction, high cost and high market price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the above-mentioned soft portable multispectrum composite camouflage material includes:

[0047] (1) On the side of the inner layer matrix 2 close to the target, evenly brush the acrylic waterproof paint added with fish beads and camouflage pigments, as the waterproof inner layer 1, with a thickness within 1-3mm;

[0048] (2) Place the glossy aluminum foil with high infrared reflection ability facing the barrier target, and glue it to the inner substrate 2 with fish bead glue;

[0049] (3) Mix ferrite powder, graphite fine powder, fish pearl glue, and camouflage pigment evenly, and paint on the aluminum foil as the transition layer 4, with a thickness within 1-3mm;

[0050] (4) Evenly paint the mixture of ferrite powder, graphite fine powder and epoxy adhesive on the transition layer 4, as the wave-absorbing layer 5, with a thickness between 2mm-5mm;

[0051] (5) When the wave-absorbing layer 5 is half dry, the outer layer substrate 6 is bonde...

Embodiment 1

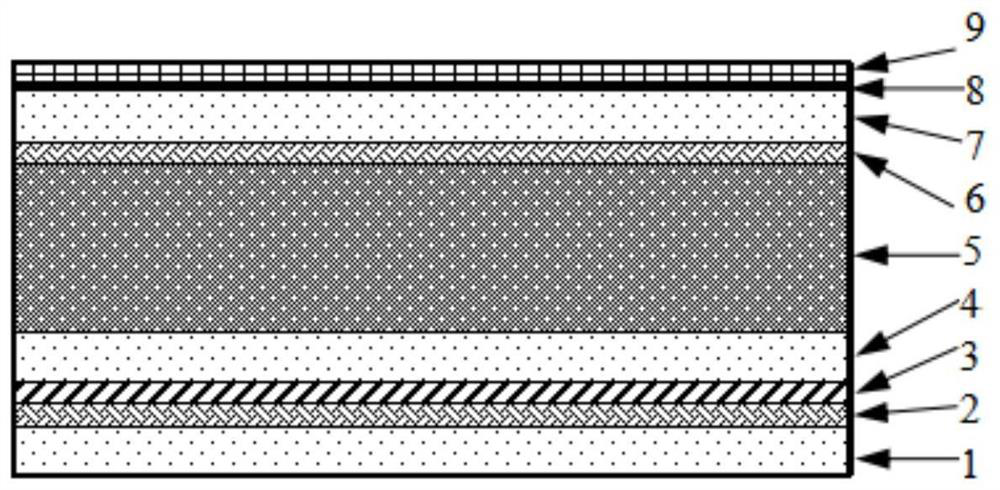

[0059] The novel soft portable multispectral composite camouflage material of this embodiment is a multifunctional layered structure, such as figure 1 As shown, from bottom to top, there are waterproof inner layer 1, inner layer substrate 2, infrared reflective layer 3, transition layer 4, wave-absorbing layer 5, outer substrate 6, waterproof outer layer 7, heat insulation layer 8 and camouflage layer 9, wherein the infrared reflective layer 3 is aluminum foil of 0.012 mm, and the wave-absorbing layer 5 contains ferrite powder, graphite fine powder, and epoxy adhesive, with a thickness of 4 mm.

[0060] The preparation method of the novel soft multispectrum composite camouflage material of this embodiment comprises the following steps:

[0061] (1) On the side of the inner substrate 2 close to the target, evenly paint a layer of waterproof inner layer 1 with a thickness of about 2mm, and let it dry naturally; the waterproof inner layer 1 includes acrylic waterproof paint, fish...

Embodiment 2

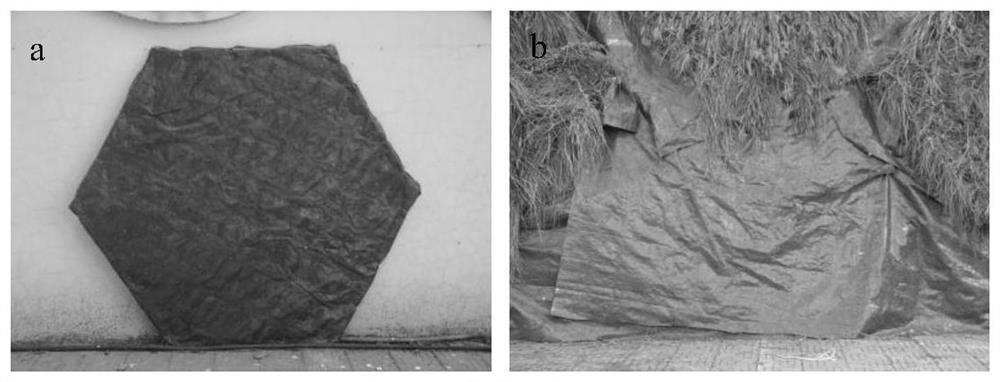

[0076] The novel multi-band composite vegetation camouflage material of this embodiment is a multifunctional layered structure, such as Figure 4 As shown, from bottom to top, it is composed of waterproof inner layer 1, inner layer substrate 2, infrared reflective layer 3, transition layer 4, wave-absorbing layer 5, outer layer substrate 6 and vegetation layer 10, wherein the infrared reflective layer 3 is 0.012 mm aluminum foil, the wave-absorbing layer 5 contains ferrite powder, graphite fine powder, and epoxy adhesive, with a thickness of 4 mm.

[0077] The preparation method of the novel multi-band composite vegetation camouflage material of the present embodiment comprises the following steps:

[0078] (1) On the side of the inner substrate 2 close to the target, evenly paint a layer of waterproof inner layer 1 with a thickness of about 2mm, and let it dry naturally; By weight, acrylic waterproof paint 65%, fish beads 30%, camouflage pigment 5%;

[0079] (2) Place the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com