Mixing black maintaining ink, ink layer structure and laser code carving method

A technology for retaining ink and ink layer, which is applied in the field of laser engraving, can solve the problems of printing cost, low efficiency, fast information update and unstockable information such as variable graphic information with black surface on light color surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

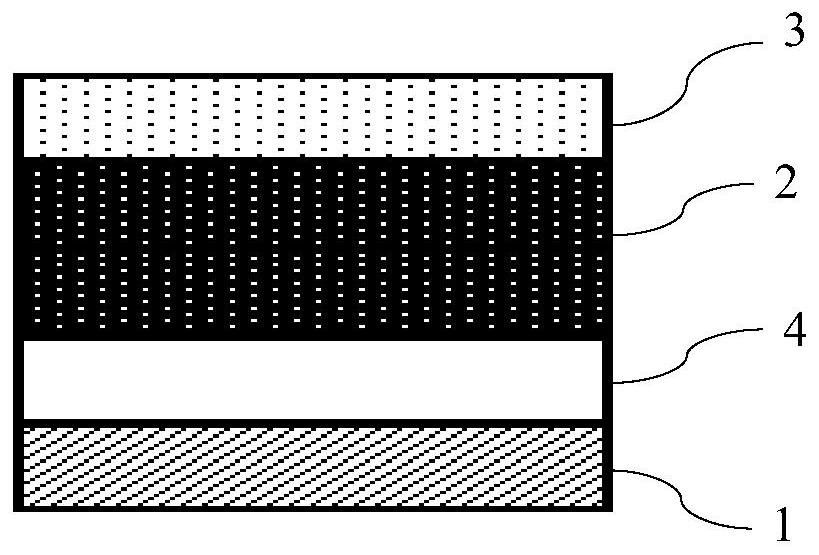

[0046] Such as figure 1 As shown, white ink is sequentially printed on the PET material by screen printing technology to form a white ink layer 4, a black reserved ink is printed to form a retained ink layer 2 close to black, and a gray ink is printed to form an ink layer 3 to be engraved. Wherein, the printing times of allocating black reserved ink is twice. The mass-to-number ratios of C, M, and Y inks in the prepared black reserved ink are: 55 parts of cyan ink, 45 parts of magenta ink, and 15 parts of yellow ink. The mesh number of screen printing is 300 mesh; the above-mentioned cyan ink, magenta ink, yellow ink, white ink and gray ink adopt UV ink, and use UV drying after printing each layer.

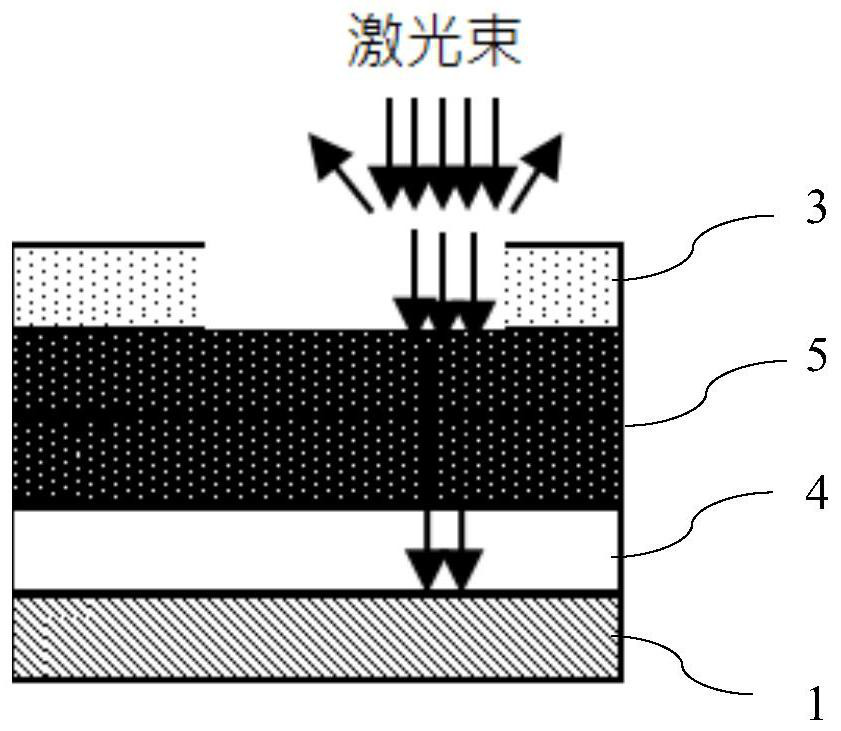

[0047] After printing, the fiber laser engraving machine is used to engrave the gray ink layer 3 to be engraved according to the designed graphic, and the exposed part is close to the black reserved ink layer 2; wherein, the fiber laser wavelength is 1-2 microns, The power of la...

Embodiment 2

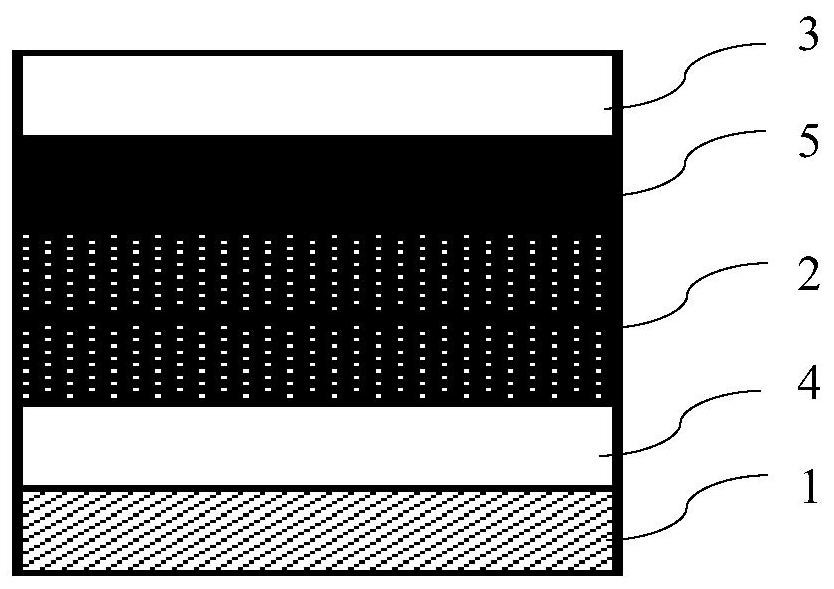

[0049] Such as image 3 As shown, on the PC material, the white ink is printed sequentially by screen printing technology to form a white ink layer 4, the black reserved ink is printed to form a retained ink layer 2 close to black, the pure black ink is printed to form a protective ink layer 5, and the white ink is printed An ink layer 3 to be engraved is formed. Wherein, the printing times of allocating black reserved ink is twice. The mass-to-number ratios of C, M, and Y inks in the prepared black reserved ink are: 35 parts of cyan ink, 25 parts of magenta ink, and 35 parts of yellow ink. The screen mesh number of screen printing is 380 mesh; the above-mentioned cyan ink, magenta ink, yellow ink, white ink, and pure black ink use UV ink, and each layer is dried by UV after printing.

[0050] After printing, the fiber laser engraving machine is used to engrave the white ink layer 3 to be engraved according to the designed graphic, and the exposed part is close to the black ...

Embodiment 3

[0052] On the PET material, white ink is sequentially printed by screen printing technology to form a white ink layer 4, a black reserved ink is printed to form a retained ink layer 2 close to black, and a gray ink is printed to form an ink layer 3 to be engraved. Wherein, the printing times of allocating black reserved ink is twice. The mass-to-number ratios of C, M, and Y inks in the prepared black reserved ink are: 60 parts of cyan ink, 50 parts of magenta ink, and 10 parts of yellow ink. The mesh number of screen printing is 300 mesh; the above-mentioned cyan ink, magenta ink, yellow ink, white ink and gray ink adopt UV ink, and use UV drying after printing each layer.

[0053] After printing, the fiber laser engraving machine is used to engrave the gray ink layer 3 to be engraved according to the designed graphic, and the exposed part is close to the black reserved ink layer 2; wherein, the fiber laser wavelength is 1-2 microns, The power of laser engraving equipment is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com