Device for preparing regenerated sand and stone materials from construction waste particles

A technology for construction waste and particulate matter, applied in the field of construction, can solve the problems of destroying the ecological environment, construction waste cannot be effectively recycled and reused, and waste of resources, etc., and achieves the effect of protecting the environment, preventing clogging of screens, and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

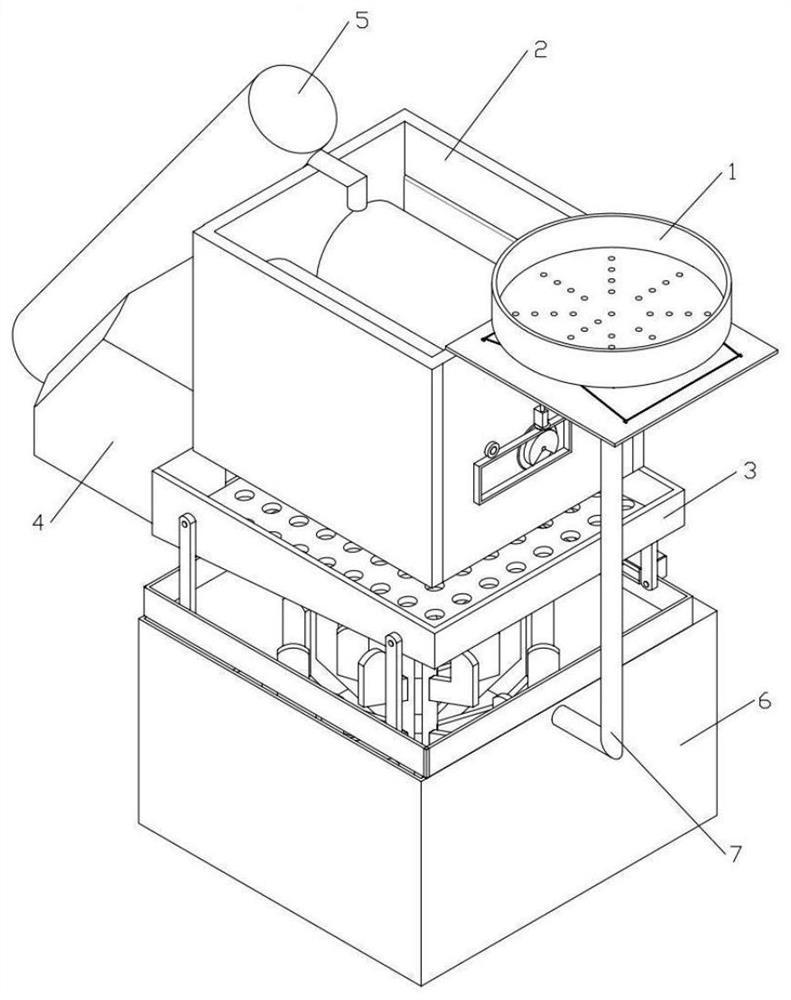

[0030] Combine below Figure 1-13 In order to solve the above technical problems, the present invention relates to the field of construction technology, more specifically, a device for producing recycled sand and gravel from construction waste particles, including a discharge device 1, a first processing device 2, a screening device 3, a second processing device Device 4, spiral elevator 5 and stirring device 6; Described discharge device 1 is fixedly connected with first processing device 2, and described first processing device 2 communicates with screening device 3, and described screening device 3 is connected with second The processing device 4 communicates, the second processing device 4 communicates with the screw elevator 5, the screw elevator 5 communicates with the first processing device 2, the screening device 3 communicates with the stirring device 6, and the stirring The device 6 is connected to the discharge device 1 through a hose 7; the garbage particles are p...

specific Embodiment approach 2

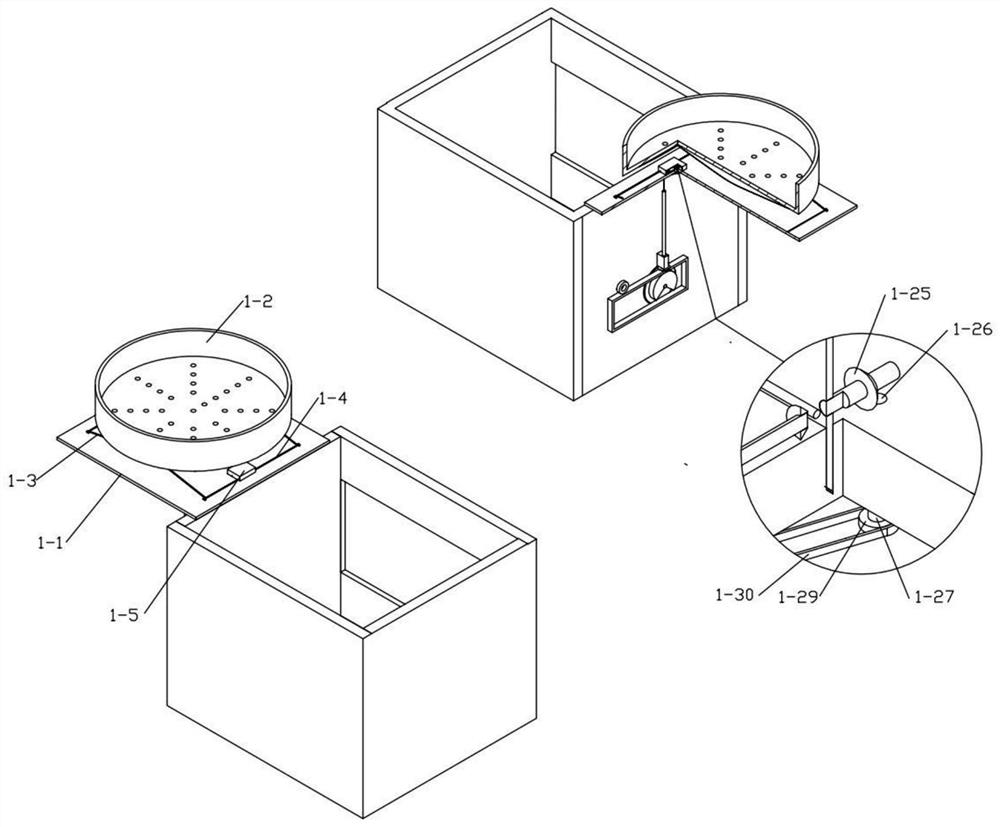

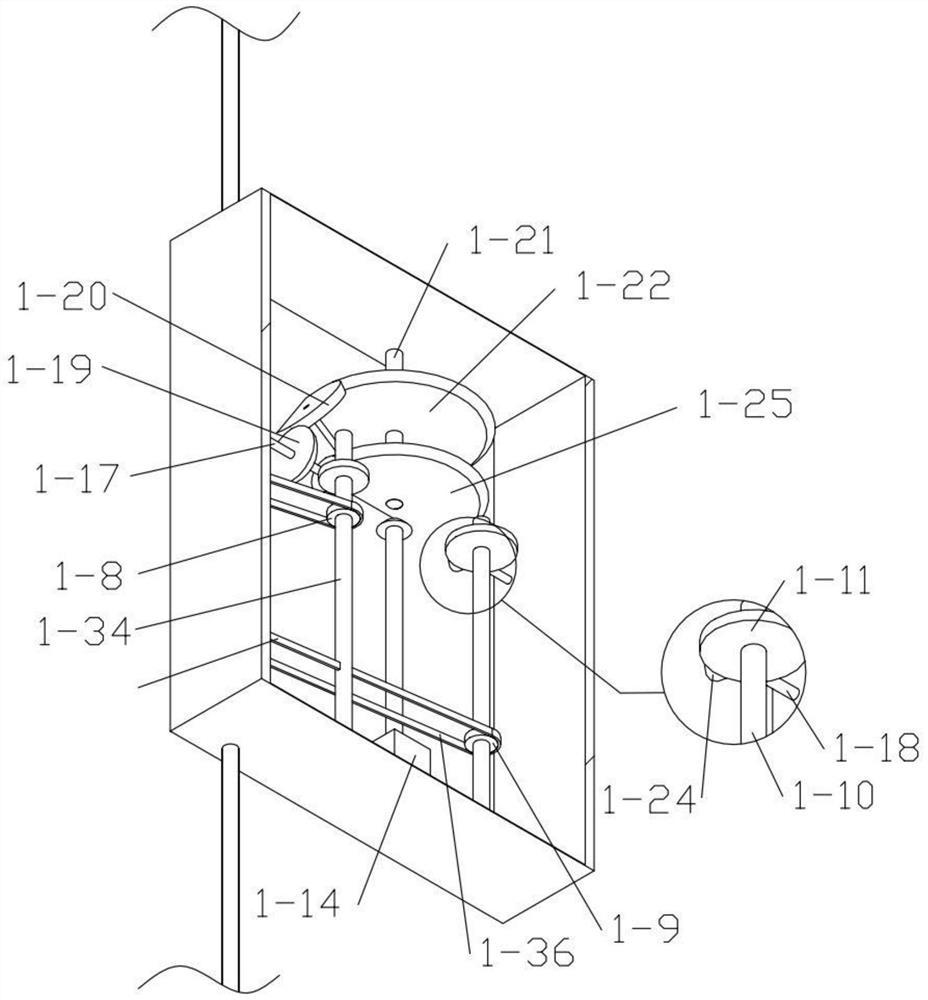

[0032] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the embodiment *, the discharge device 1 includes a positioning plate 1-1, a charging funnel 1-2, a connecting rod 1-3, a connecting rod 2 1-4, Discharge shell 1-5, discharge pulley one 1-6, discharge pulley two 1-7, discharge pulley three 1-8, discharge pulley four 1-9, discharge shaft two 1- 10. Discharge turbine 2 1-11, discharge motor 1-12, discharge screw screw 1-13, discharge screw nut 1-14, discharge worm 1-15, discharge helical gear 1-16, Direction changing shaft one 1-17, direction changing shaft two 1-18, direction changing helical gear one 1-19, direction changing helical gear two 1-20, direction changing shaft four 1-21, direction changing helical gear three 1-22 , change direction helical gear four 1-24, transmission helical gear one 1-25, transmission helical gear two 1-26, connecting shaft one 1-27, connecting shaft two 1-28, connecting pulley 1-29, connecting trans...

specific Embodiment approach 3

[0035] Combine below Figure 1-13Describe this embodiment, this embodiment will further explain the second embodiment, the first processing device 2 includes processing shaft 1 2-1, connecting helical gear 1 2-2, connecting helical gear 2 2-3, processing and crushing Gear group one 2-8, processing pulley one 2-9, processing pulley two 2-10, processing transmission belt 2-11, processing shaft two 2-12, processing crushing gear group two 2-13, rack drive belt 2 -14, processing transmission gear 2-15 and processing transmission shaft 2-16; the connection motor 1-32 is connected with the connection helical gear one 2-2 key, and the connection helical gear one 2-2 is connected with the connection helical gear two 2 -3 meshing, the connecting helical gear two 2-3 is keyed to the connecting shaft three 2-4, the connecting shaft three 2-4 is keyed to the incomplete gear 2-5, and the incomplete gear 2-5 Set in the rack frame 2-6, and the incomplete gear 2-5 meshes with the rack frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com