A construction method for pipeline trench excavation

A construction method and pipeline trench technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of high material cost and increased engineering volume, and achieve the goals of improving stability, reducing excavation depth, and increasing density and hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings.

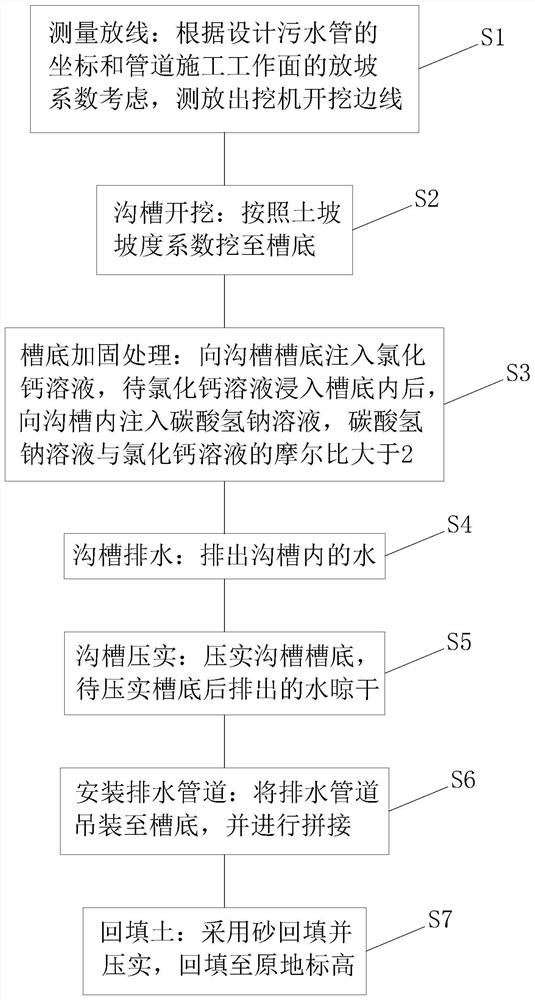

[0040] refer to figure 1 , is a pipeline trench excavation construction method disclosed in the present invention, the method comprises the following steps:

[0041] S1: Measure and set out: According to the coordinates of the designed sewage pipe and the grading coefficient of the pipeline construction face, measure and set out the excavation side line of the excavator; the measurement control point must be introduced from the wire point that has been reviewed in this project, and the temporary control point must be Use after supervision and review. According to 1:0.5 grading consideration.

[0042] S2: trench excavation: excavate to the bottom of the trench according to the slope coefficient of the soil slope; part of the earth on the trench is carried out by ordinary PC200 excavators, and the excavated earth is directly transported by earth transport vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com