Dorsal bar flexural rigidity reinforcing device

A strengthening device and a technology of bending stiffness, which is applied in the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc. Long and other problems, to achieve a good reinforcement effect, eliminate deformation, and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

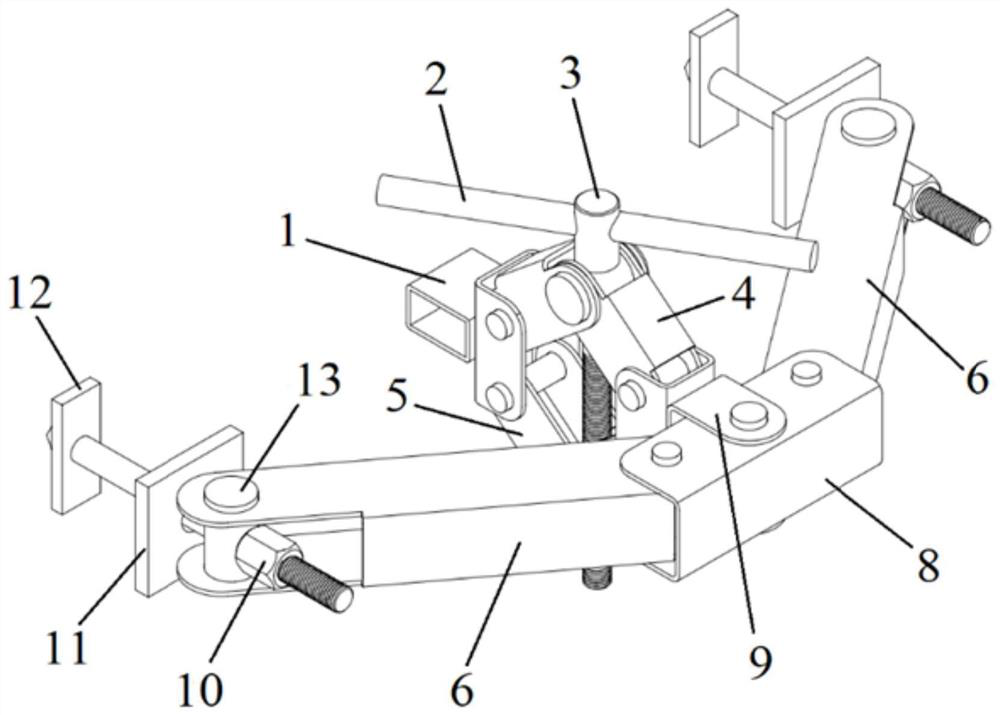

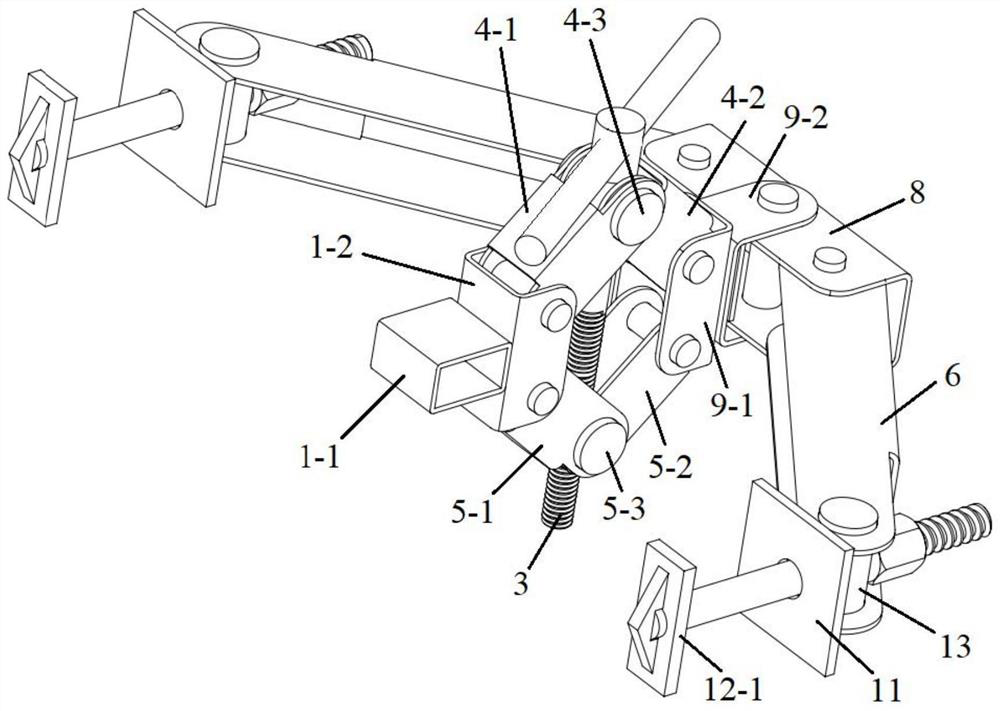

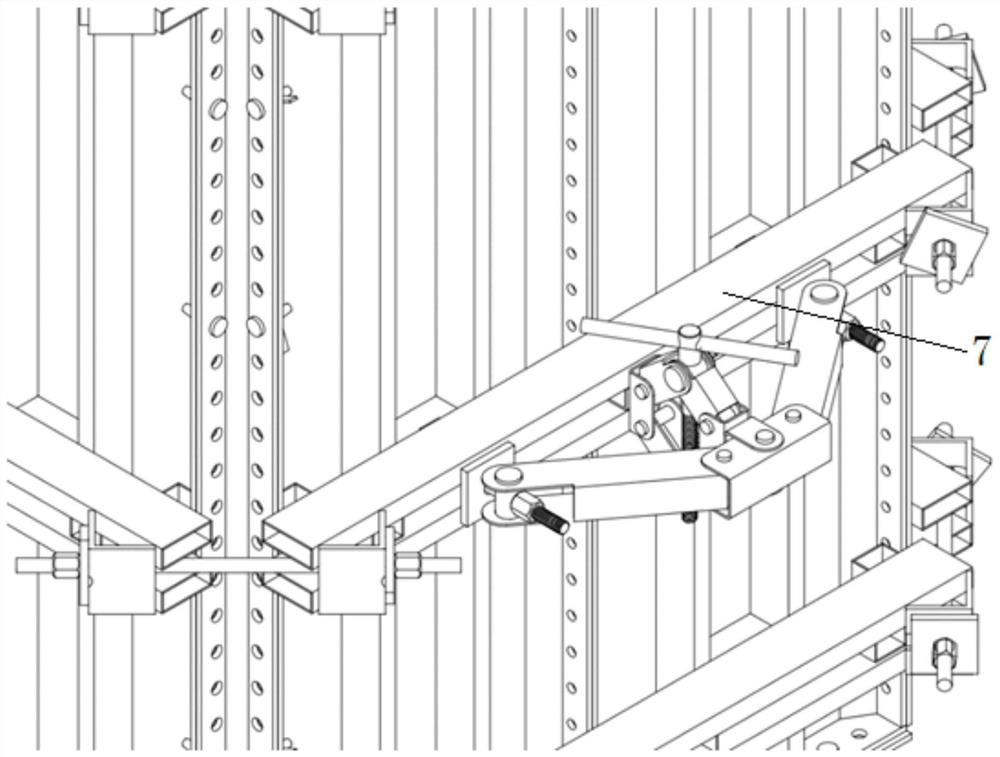

[0034] Such as Figure 1 to Figure 3 As shown, a back corrugated bending rigidity strengthening device includes a positioning block 1, a screw rod 3, a connecting rod 4, a connecting rod 2 5, a support rod 6, a U-shaped connecting rod 8, a nut 10, a T-shaped bolt 12, Hole pin 13;

[0035] Described connecting rod one 4 comprises hinged bar A4-1, bar B4-2 and the first column pin with hole 4-3, and the first end of bar A, bar B is hinged by the first column pin with hole, described A through hole is opened on the first pin with a hole, and the through hole is opened along the diameter direction of the first pin with a hole;

[0036] Described connecting rod two 5 comprises hinged bar C5-1, bar D5-2 and the second pin with hole 5-3, and the first end of bar C, bar D is hinged by the second pin with hole, described The second pin with holes is provided with an internally threaded hole matched with the screw mandrel 3, and the internally threaded hole is opened along the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com