Tool deformation energy measuring device

A technology for measuring devices and deformation energy, applied in measuring devices, instruments, etc., can solve problems such as tool temperature rise and machining errors, and achieve the effect of offsetting bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to clearly illustrate the technical characteristics of this patent, the following describes this patent in detail through specific implementation methods and in conjunction with the accompanying drawings.

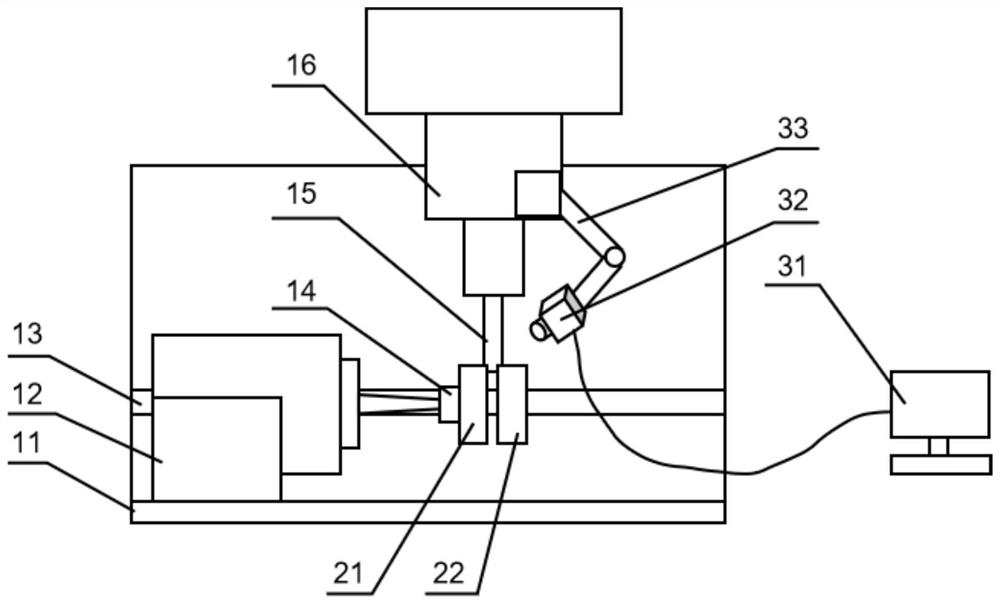

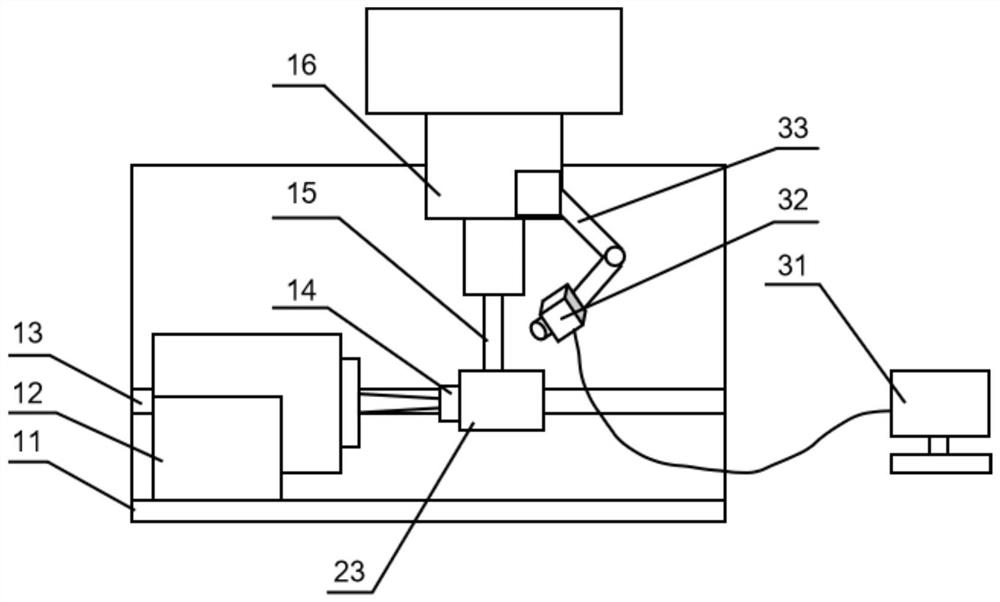

[0035] The invention as Figure 1-8 As shown, it includes a measurement platform and a test piece; the measurement platform includes an L-shaped substrate 11, a support rail 13, an exciter 12, a machine tool 16, a mandrel 15, a magnetic base 33, and an infrared thermal imager temperature measurement system;

[0036] The L-shaped base plate 11 includes a bottom plate and a vertical plate connected as one, the support rail 13 is horizontally arranged and fixedly connected to the vertical plate, the test piece is detachably connected to the support rail 13 through a bracket, and the test A force sensor 14 is fixedly connected on the part;

[0037] The vibrator 12 is fixedly connected to the base plate and is on one side of the support guide rail 13. The output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com