A new energy vehicle water-cooled condenser

A new energy vehicle, water-cooled technology, applied in the direction of machines/engines, chemical instruments and methods, mechanical equipment, etc., can solve problems such as damage, dirt, and reduce heat transfer effects, so as to prevent excessive friction and avoid the formation of dirt , to avoid the effect of heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

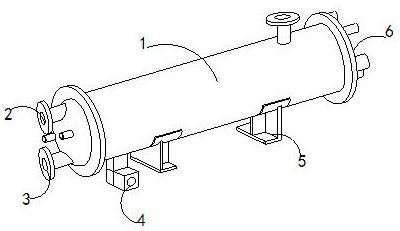

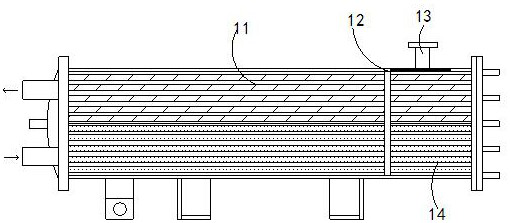

[0025] Such as Figure 1-Figure 6 Shown:

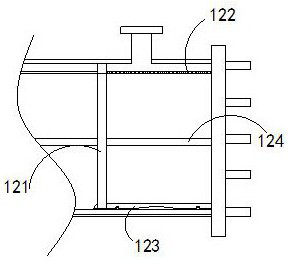

[0026] The present invention is a water-cooled condenser for a new energy vehicle, the structure of which includes a condensation mechanism 1, a water outlet 2, a water inlet 3, a smoke outlet pipe 4, a fixing frame 5, and a connecting shaft 6, and the water outlet 2 is installed on the condensation mechanism 1 On the left side of the condensing mechanism 1, the water inlet 3 is installed on the left side of the condensing mechanism 1, the smoke outlet pipe 4 is embedded in the lower end of the condensing mechanism 1, the fixing frame 5 is attached to the lower surface of the condensing mechanism 1, and the The connecting shaft 6 is embedded in the right end of the condensing mechanism 1. The condensing mechanism 1 is provided with a heat exchange pipe 11, a scraping mechanism 12, a smoke inlet pipe 13, and a condensation pipe 14. The right end of the scraping mechanism 12 is connected to the connecting shaft 6, the scraping mechanis...

Embodiment 2

[0034] Such as Figure 7-Figure 8 Shown:

[0035] Wherein, the sliding mechanism a4 is provided with a force receiving ring a41 and a force receiving mechanism a42, the force receiving ring a41 is attached to the surface of the force receiving mechanism a42, and the outer side of the force receiving ring a41 is attached to the surface of the drainage mechanism a1. Inside, the force receiving ring a41 is a triangular ring structure, located on the same central axis as the force receiving mechanism a42, so as to prevent the heat exchange tube 11 and the lower surface of the condenser tube 14 from being attached to the lower surface of the heat exchange tube 11 to cool and condense to form dirt, and to remove the dirt.

[0036] Wherein, the stressed ring a41 is provided with a stressed shaft b1, a compression plate b2, a gap plate b3, and a spring b4, the lower end of the stressed shaft b1 is embedded in the upper end of the spring b4, and the compressed plate b2 is attached to On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com