Oil pressure drive system and gate valve

A drive system and oil pressure technology, applied in the direction of sliding valves, fluid pressure actuators, valve details, etc., can solve the problems of high power consumption of servo motors, improve operational reliability, reduce power consumption, and improve operational reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

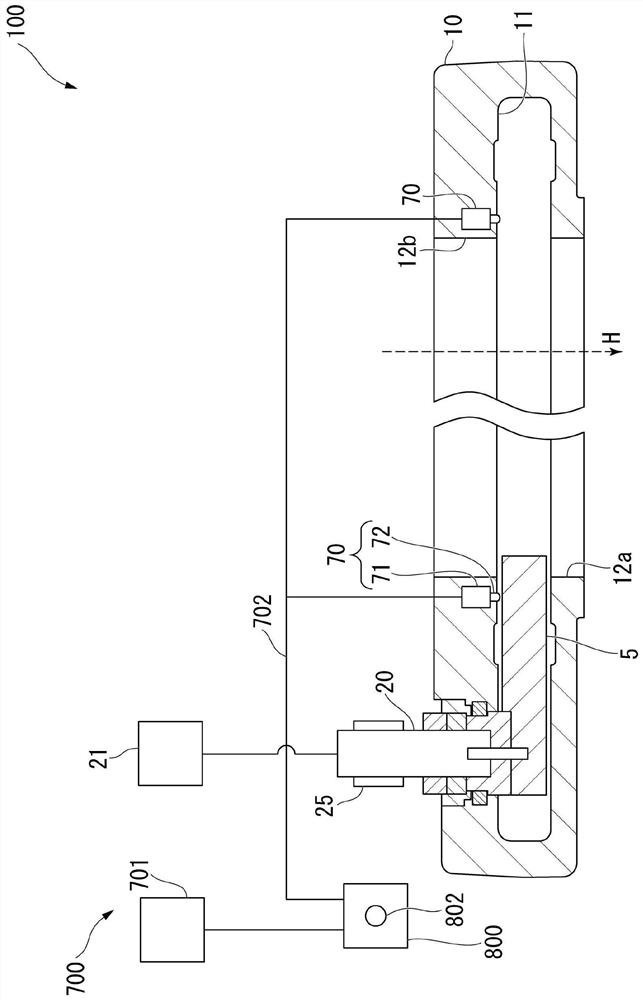

[0525] Next, examples of the present invention will be described.

[0526] Here, performance analysis will be described as a specific example of the hydraulic drive system of the present invention.

[0527]

[0528] First, the type of the motor 705m, the structure of the counter-rotation countermeasure required for this, the electric power required at this time, and the life of the combined structure are analyzed.

[0529] Here, as the motor 705m, a brushed DC motor, a coreless brushless DC motor, and a stepping motor are analyzed. Also, analyze the need for cogging torque countermeasures for these motors.

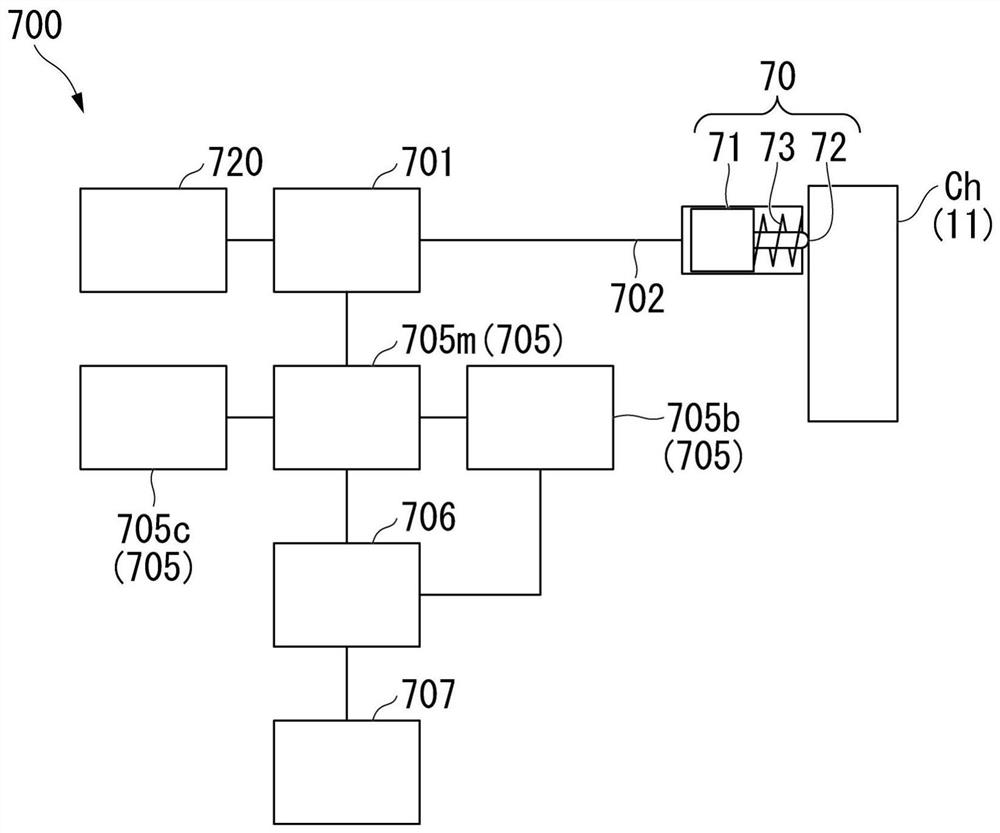

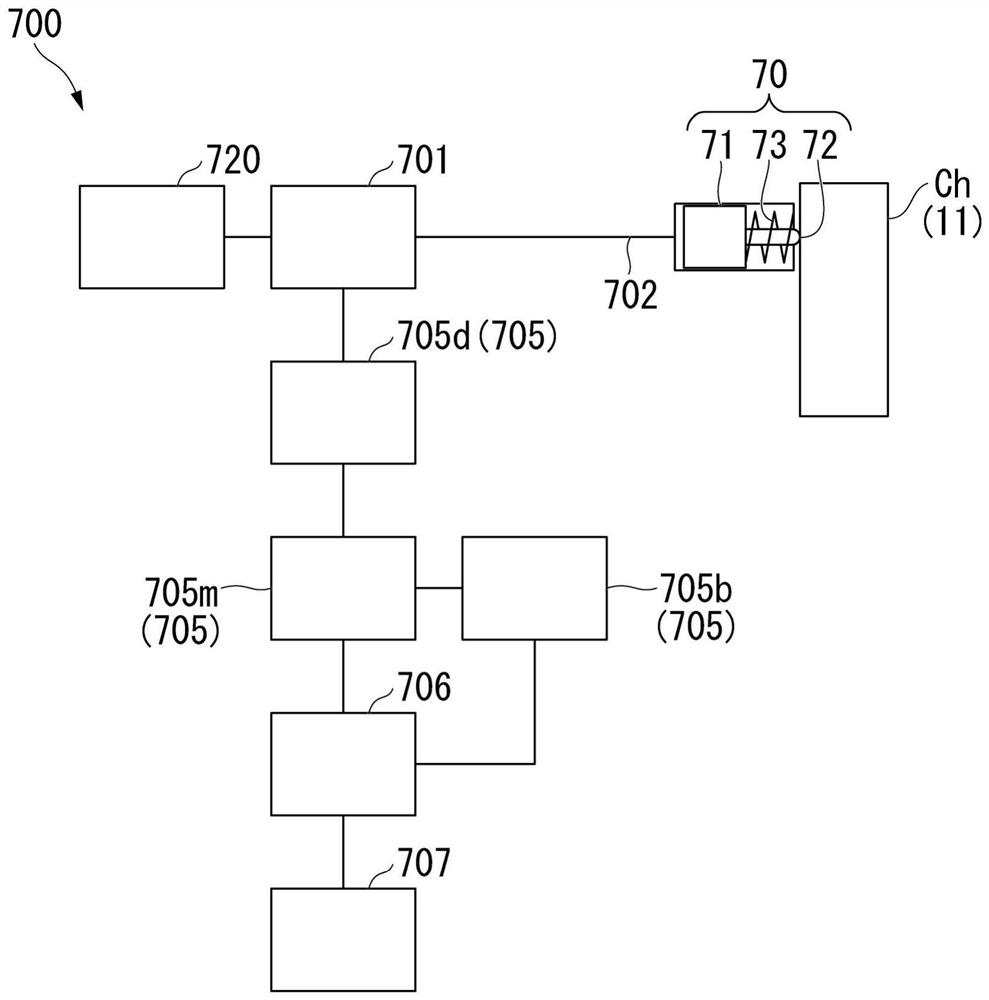

[0530] As the structure of the counter-rotation countermeasure, the solenoid valve, the field clutch 705d and the field brake 705b for preventing the reverse rotation of the drive system at the time of oil pressure reverse flow are analyzed. In addition, it is analyzed whether the regenerative current processing unit 705c is necessary.

[0531] In addition, the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com