Automatic chemical supply device

An automatic supply and chemical technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem of unsealable space around hoses and joints, leakage of chemical fumes, and musculoskeletal system diseases of staff To achieve the effect of preventing musculoskeletal system diseases and improving work convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

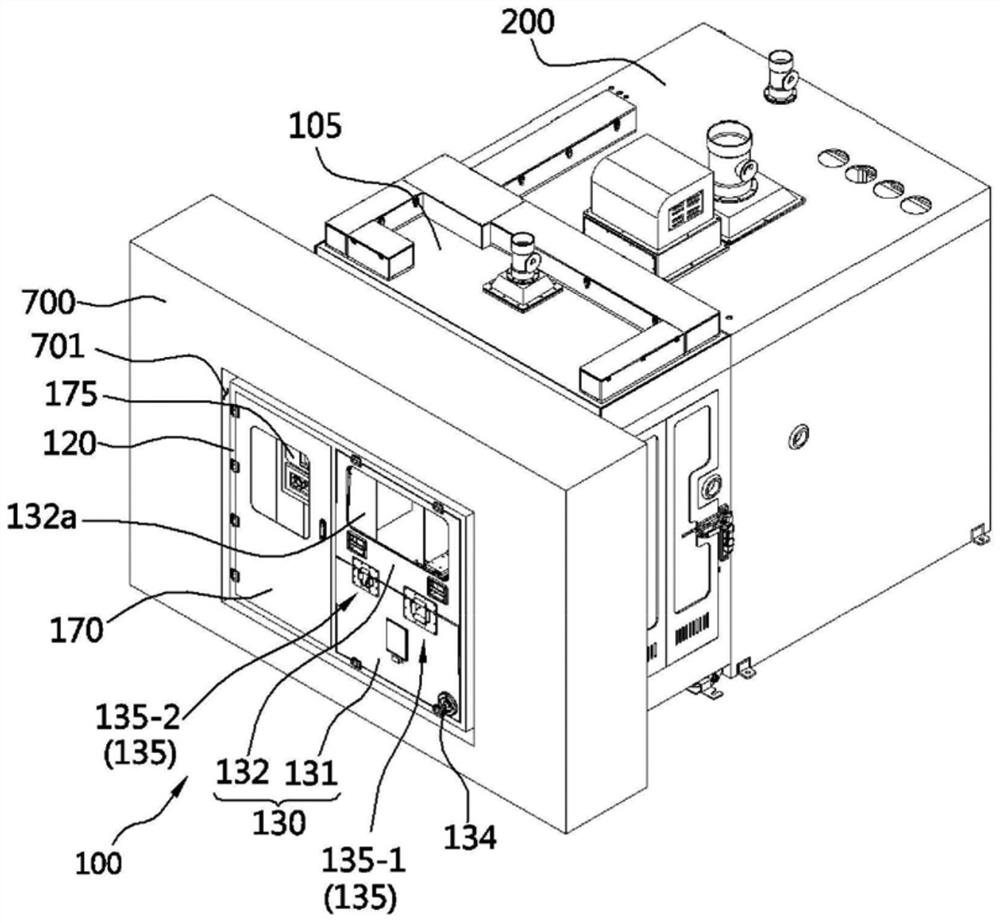

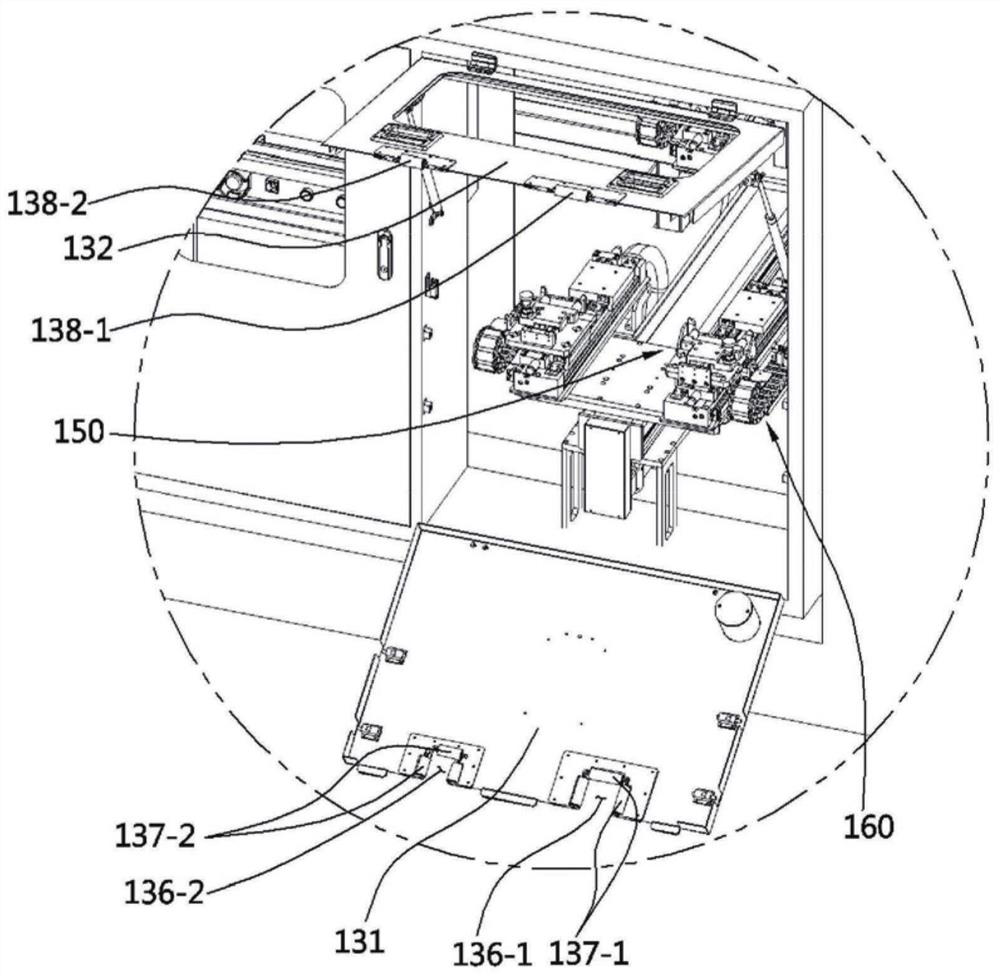

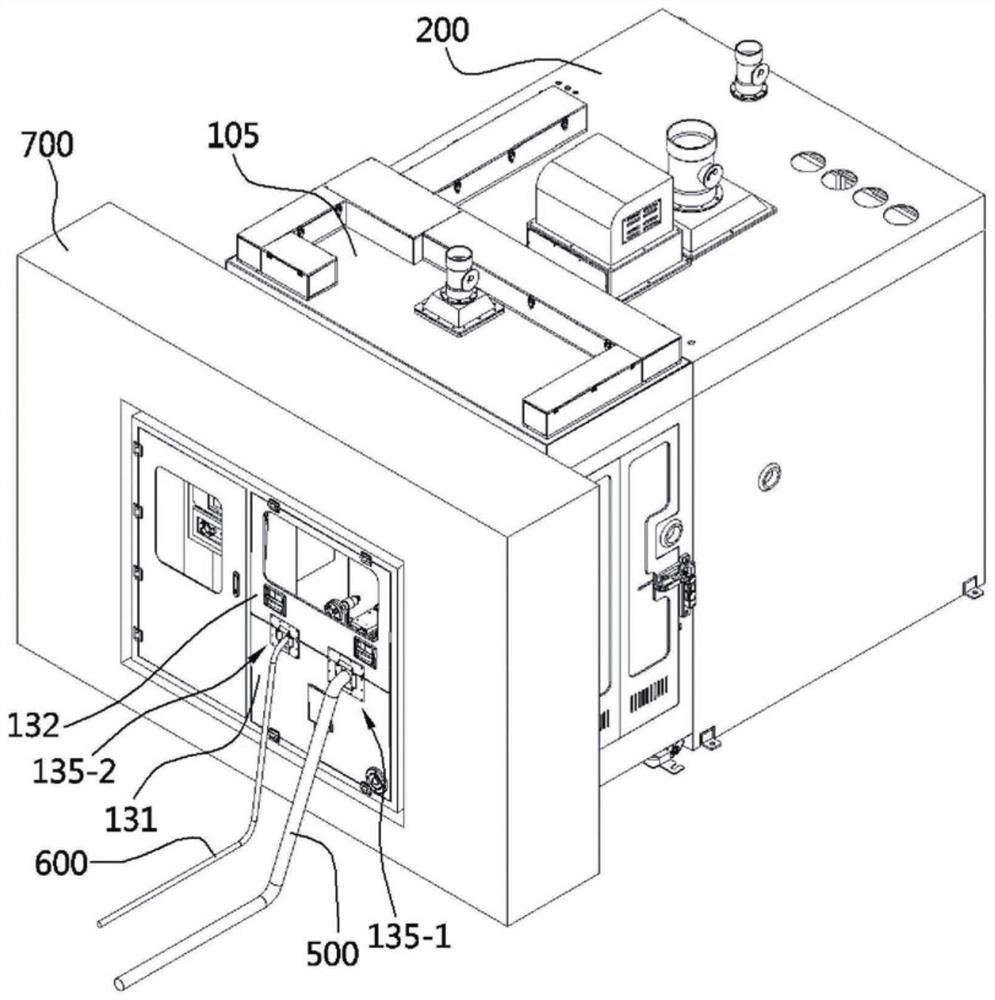

[0070] The automatic chemical supply device of the present invention will be described in detail below with reference to the drawings.

[0071] Reference Figure 1 to Figure 4 , The automatic chemical supply device 100 of the present invention is a chemical female connector 210 ( Figure 5 ) A device that automatically connects the chemical male connector 510 and the nitrogen male connector 610 to the nitrogen female connector (not shown). The chemical male connector 510 and the nitrogen male connector 610 are connected to the chemical tank of the tank lorry (not shown) Show) on the end of the chemical hose 500 and the nitrogen hose 600.

[0072] When referring to the directions below, taking the above-mentioned screen door 130 as a reference, the direction where the tanker and the operator are located is the rear, and the direction where the above-mentioned housing body 200 is located is the front.

[0073] The above-mentioned automatic chemical supply device 100 is composed of a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com