Method for optimizing power generation performance of wind turbine generator under low air density

A technology of air density and wind turbines, applied in design optimization/simulation, electrical digital data processing, computer-aided design, etc., can solve the problem that wind turbines cannot maintain the maximum power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

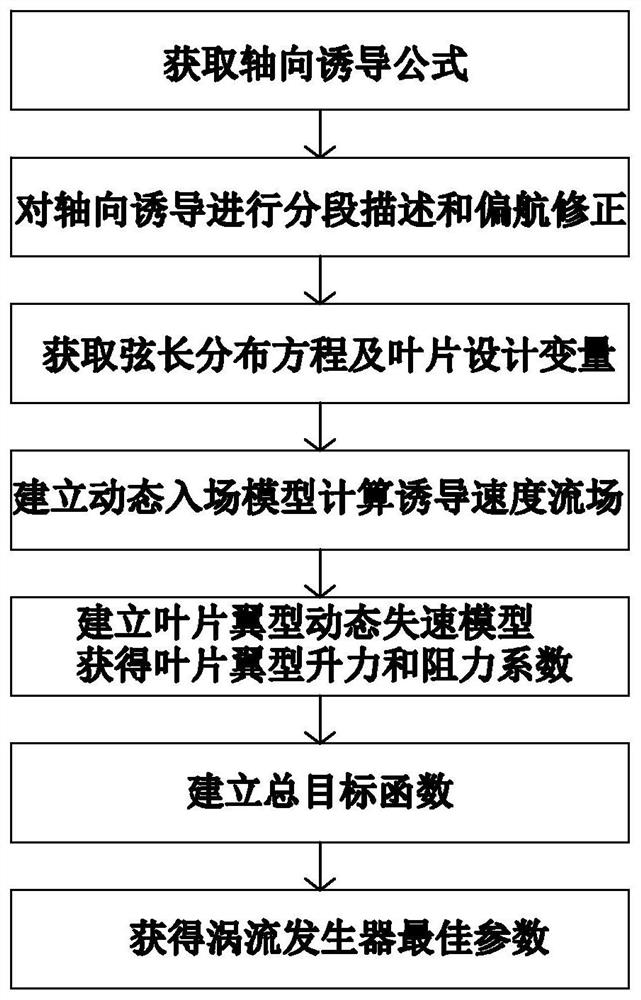

[0110] In this embodiment, a method for optimizing the power generation performance of wind turbines under low air density, such as figure 1 shown, including the following steps:

[0111] S1: Obtain the axial induction formula;

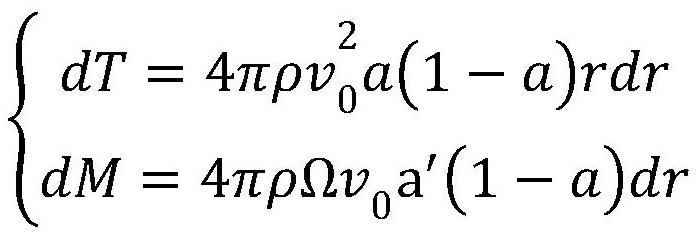

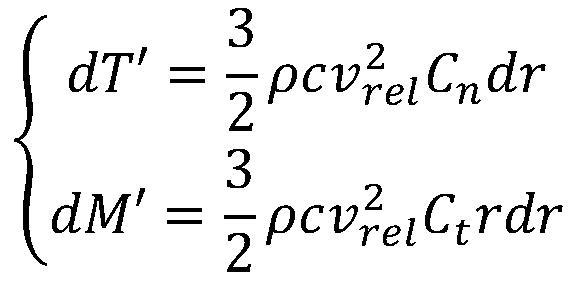

[0112]S11: According to the blade element momentum theory, the aerodynamic disc momentum theory and the blade element theory are used to divide the wind rotor plane into some ring segments dr in the radial direction through the one-dimensional blade element momentum theory, and it is assumed that each ring interacts with other rings independent. When the momentum theorem is applied to an independent ring, the thrust and torque on the ring can be obtained

[0113]

[0114] Among them, v 0 is the incoming flow velocity in front of the wind rotor, ρ is the air density, a is the axial induction factor, a'=ω / 2Ω is the circumferential induction factor, ω is the circumferential induced angular velocity at the ring, and Ω is the rotational angular veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com