Universal tool for replacing insulator

A general-purpose tool and insulator technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of many limiting factors, undiscovered patent publications, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0044] The raw materials used in the present invention, unless otherwise specified, are conventional commercially available products; the methods used in the present invention, unless otherwise specified, are conventional methods in the art.

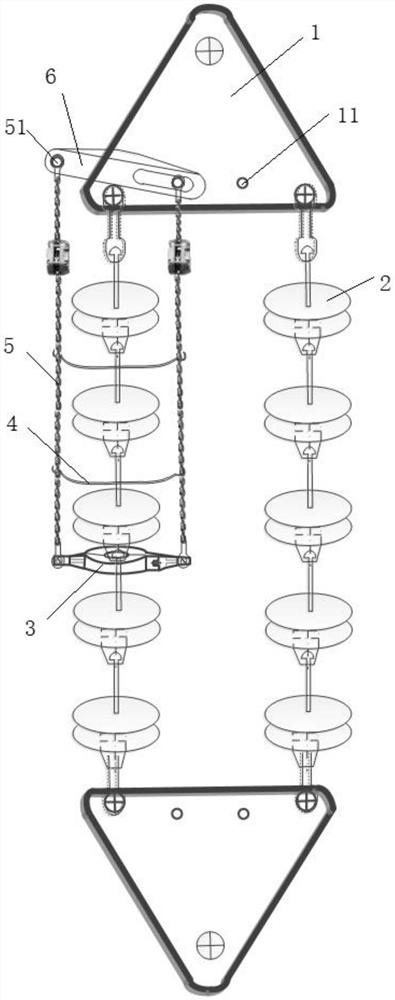

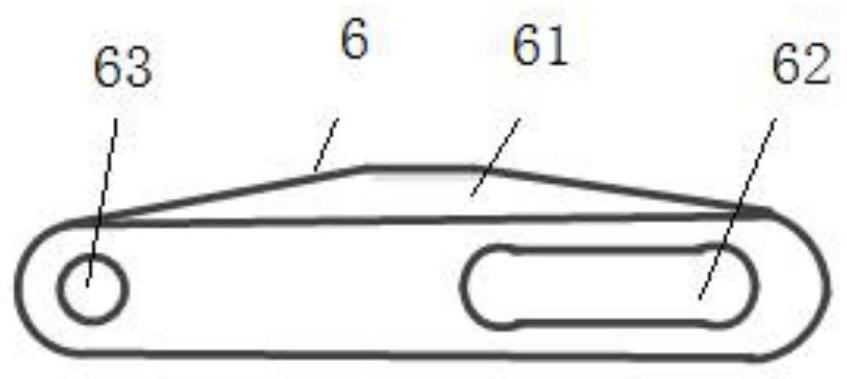

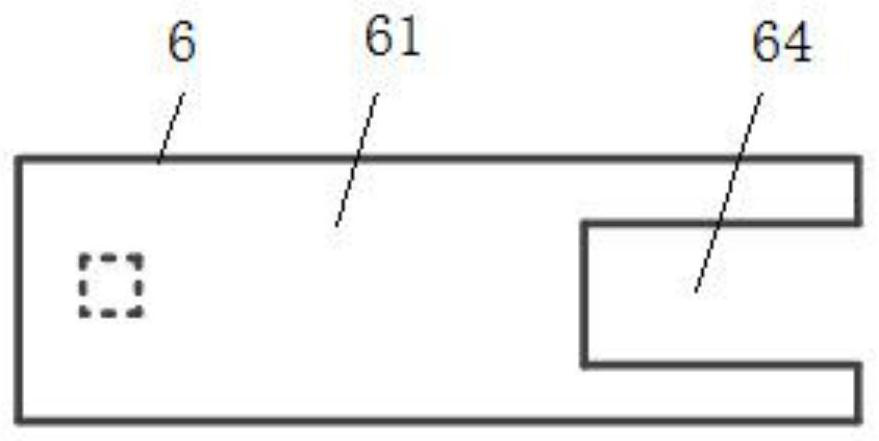

[0045] A universal tool for replacing insulators, such as figure 1 As shown, the tool includes a bowl head end fixture 3, a bottle dragging belt 4, a force-reversed chain 5 and a triangular plate fixture 6, and a plurality of insulators 2 are fixed between the two triangular plates 1, and the plurality of insulators can be used in turn. Detachable and connected, the triangular plate clamp can be detachably connected with the triangular plate, and the triangular plate clamp can also be detachably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com