a cable tie

A lap joint and cable technology, which is applied in the field of power cables, can solve problems such as high-voltage cables are prone to leakage, narrow application range, and cable aging, and achieve the effects of saving time for matching lap joint specifications, wide application range, and preventing moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

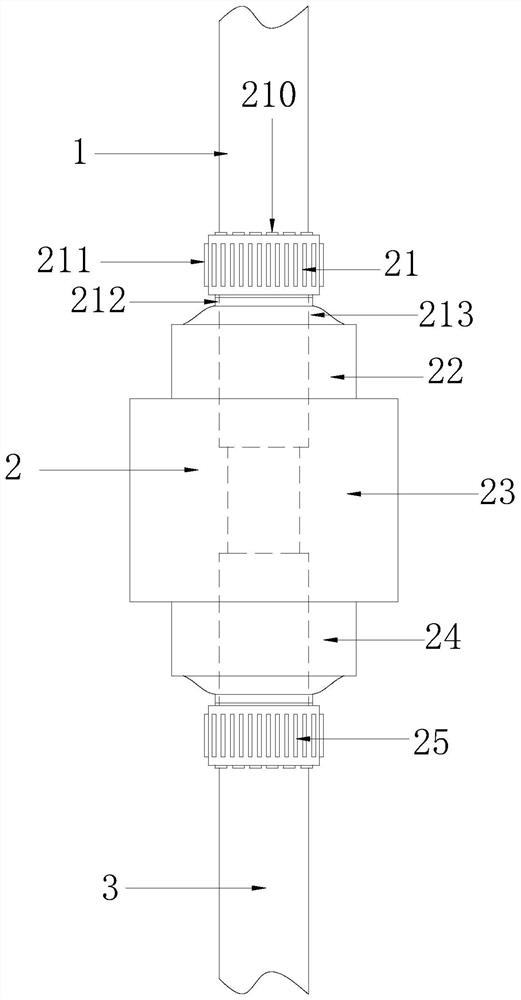

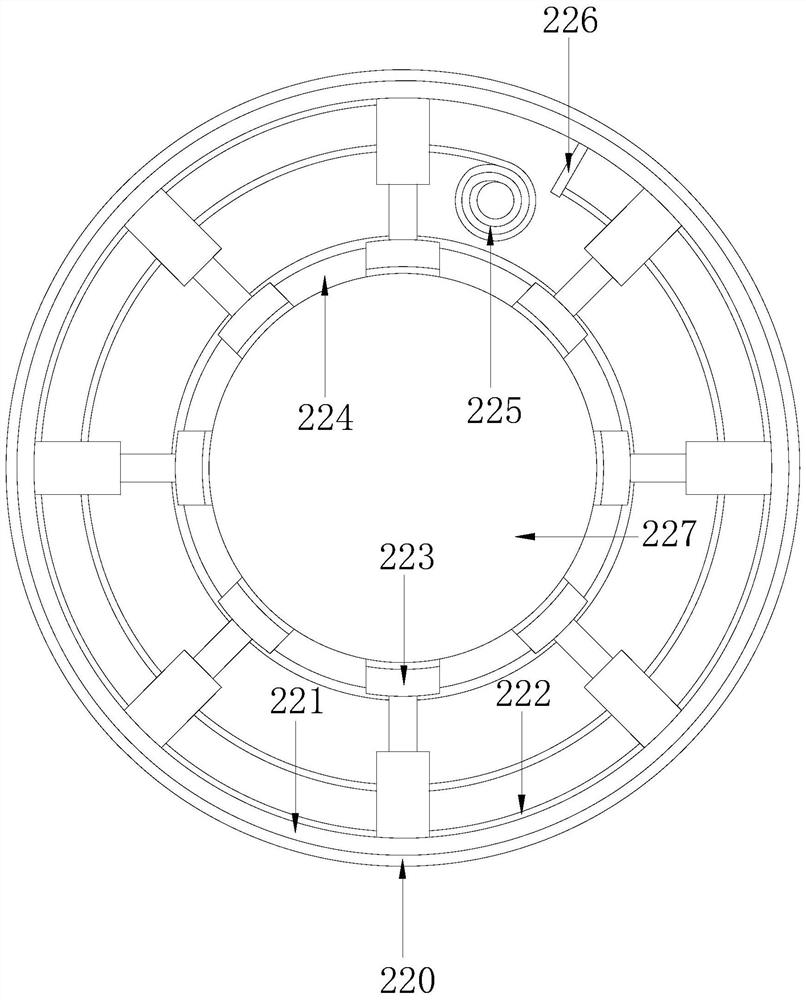

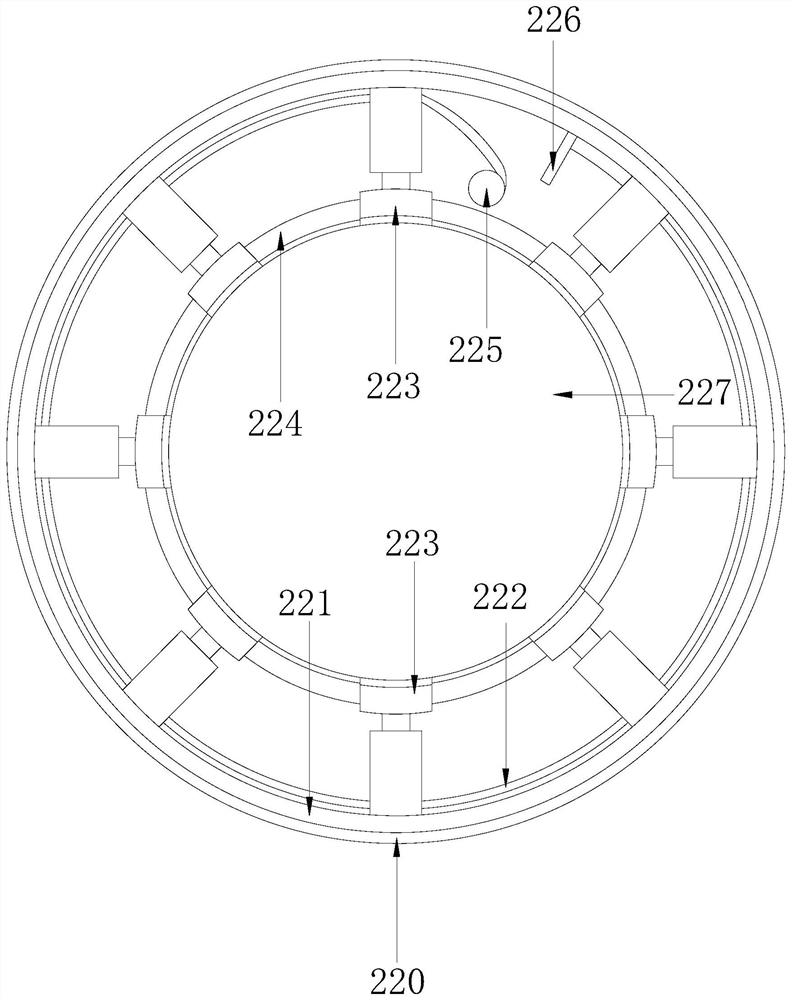

[0034] See Figure 1-3 The present invention provides a technical solution for a cable lap: there is a structure including one cable 1, a lap device 2, a cable 3, and the first cable 1 is connected to the second cable 3, the No. 1 A lap 1 is provided with a lap 1 and the second cable 3, and the lap device 2 is connected to the No. 1 cable 1, the second cable 3.

[0035] The lap device 2 includes a 1st sealing fastening mechanism 21, a 1st mounting mechanism 22, a moisture-proof casing 23, a 2nd mounting mechanism 24, a sealing fastening mechanism 25, and the moisture-proof casing 23 ends The mounting mechanism 22 is connected to the No. 1 seal fastening mechanism 21, and the other end is connected to the second mounting mechanism 24 and the second sealing fastening mechanism 25, the first seal fastening mechanism 21, No. 1 mounting mechanism 22 and No. 1 Cable 1 is connected, the secondary mounting mechanism 24, and the second sealing fastening mechanism 25 are connected to the sec...

Embodiment 2

[0043] See Figure 1-7 The present invention provides a technical solution for a cable lap: there is a structure including one cable 1, a lap device 2, a cable 3, and the first cable 1 is connected to the second cable 3, the No. 1 A lap 1 is provided with a lap 1 and the second cable 3, and the lap device 2 is connected to the No. 1 cable 1, the second cable 3.

[0044] The lap device 2 includes a 1st sealing fastening mechanism 21, a 1st mounting mechanism 22, a moisture-proof casing 23, a 2nd mounting mechanism 24, a sealing fastening mechanism 25, and the moisture-proof casing 23 ends The mounting mechanism 22 is connected to the No. 1 seal fastening mechanism 21, and the other end is connected to the second mounting mechanism 24 and the second sealing fastening mechanism 25, the first seal fastening mechanism 21, No. 1 mounting mechanism 22 and No. 1 Cable 1 is connected, the secondary mounting mechanism 24, and the second sealing fastening mechanism 25 are connected to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com