Split type camera water cooling device

A water-cooling device and a split-type technology are applied in the field of split-type camera water-cooling devices, which can solve the problem that the camera cannot be used normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

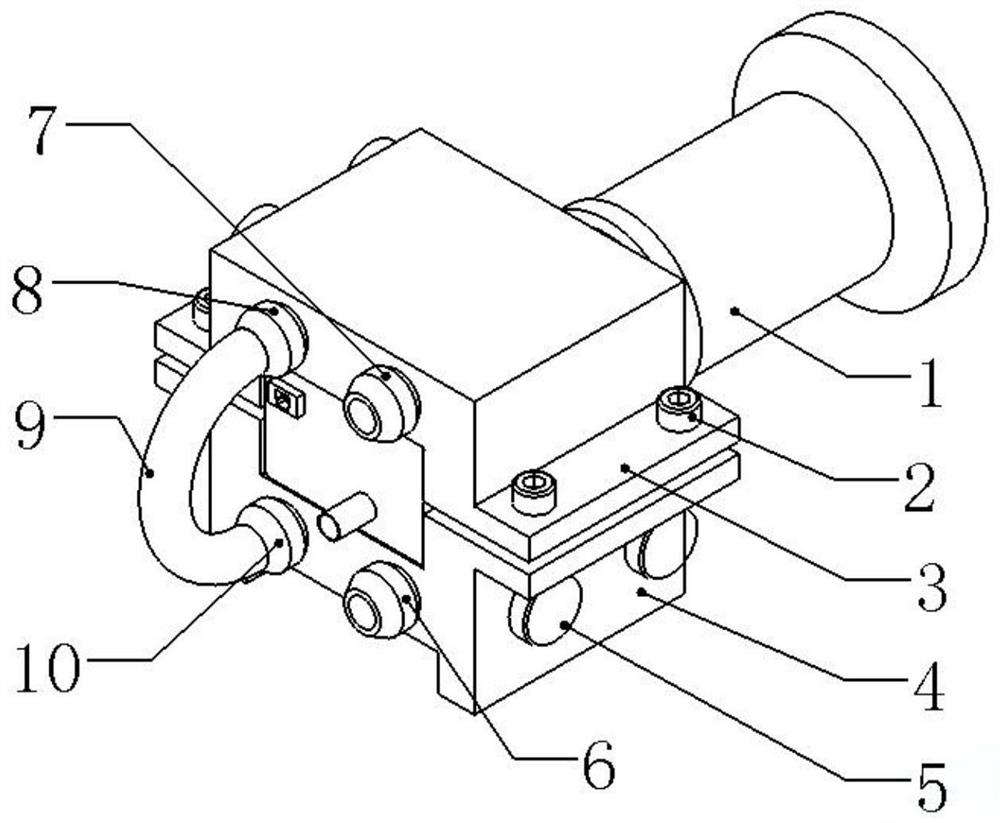

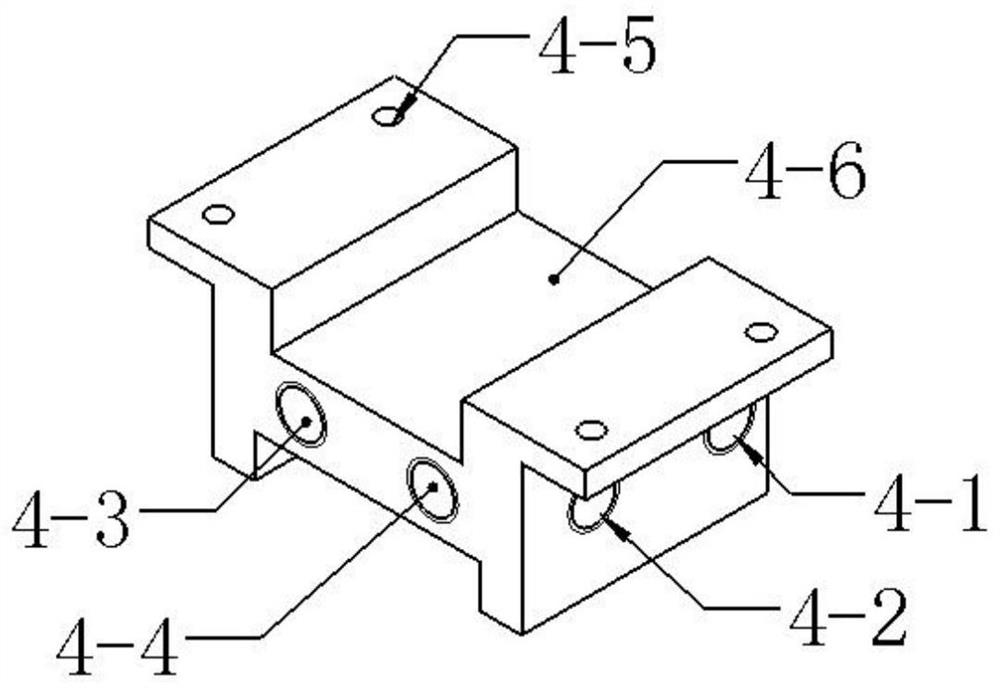

[0026] like Figure 1-3 As shown, this embodiment provides a split-type camera water-cooling device for visual inspection in the industrial field, which is mainly composed of an upper water-cooled shell 3, a lower water-cooled shell 4, and a U-shaped connecting pipe 9. The upper and lower shells are connected by four screws 2. Connect the body and clamp the camera 1, the external cooling water enters from the water inlet interface 6, flows back to the water outlet interface 10 through the cooling channel in the lower water cooling shell 4, and the cooling water continues to enter the water inlet interface 8 along the connecting pipe 9, The water flows back to the water outlet interface 7 through the cooling channel in the upper water cooling shell 3 to complete the cooling of the camera.

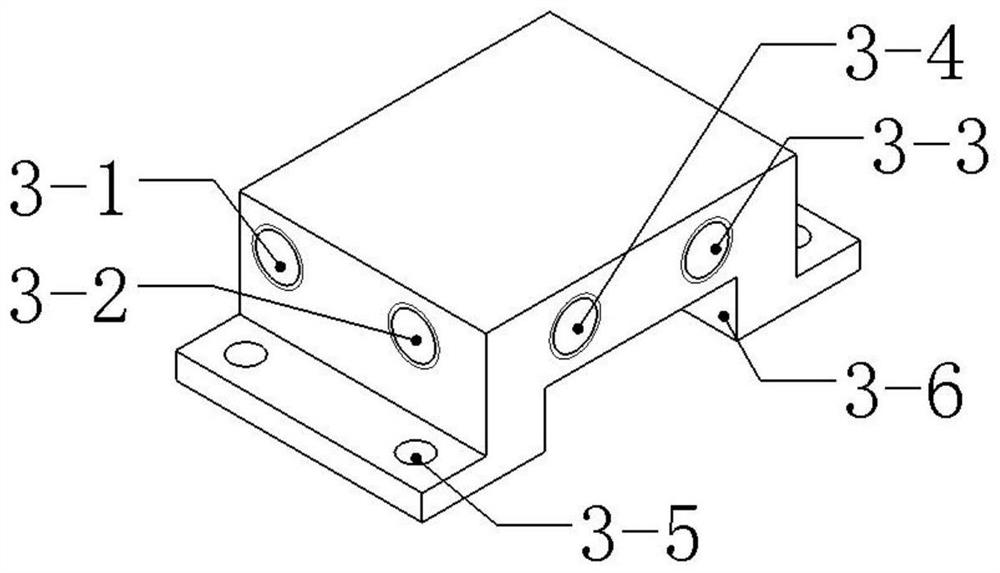

[0027] In this example, if figure 2 As shown, the upper water-cooled shell 3 has an inverted "U"-shaped structure as a whole, and an inverted "U"-shaped groove 3-6 is opened in the lower m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com