Rubber calender

A calender and rubber technology, applied in the field of rubber calender and rubber processing, can solve the problems of large shrinkage rate of film, affecting the effect of calendering, and no specific shape, and achieve the effect of reducing calendering cost, reducing waste and densifying rubber material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

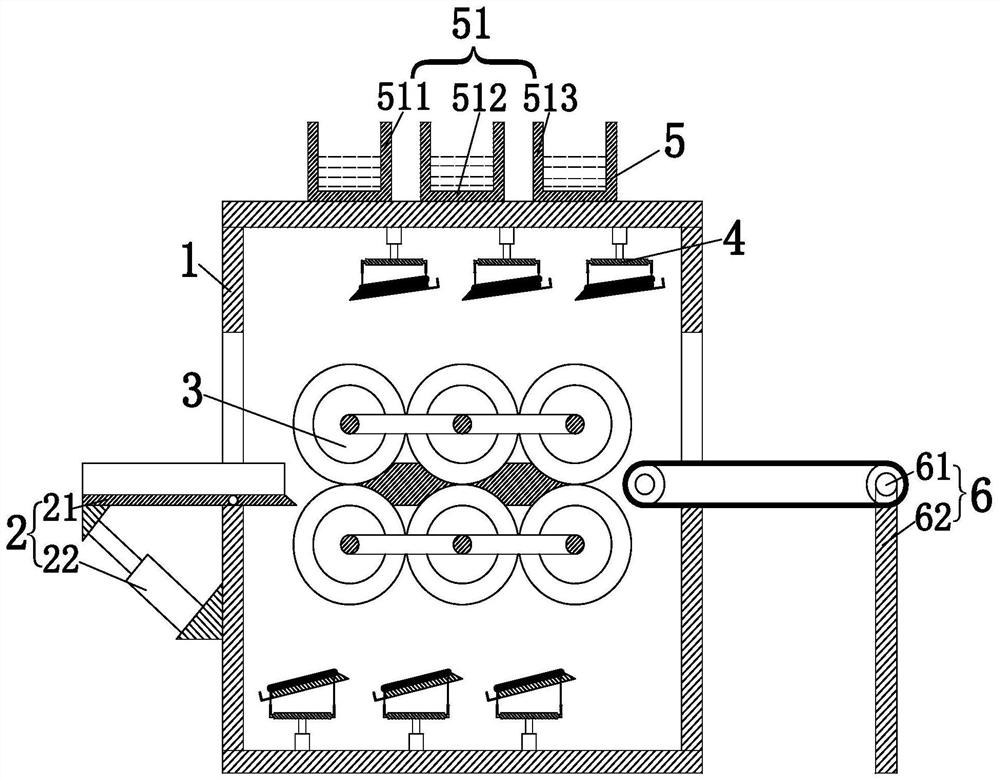

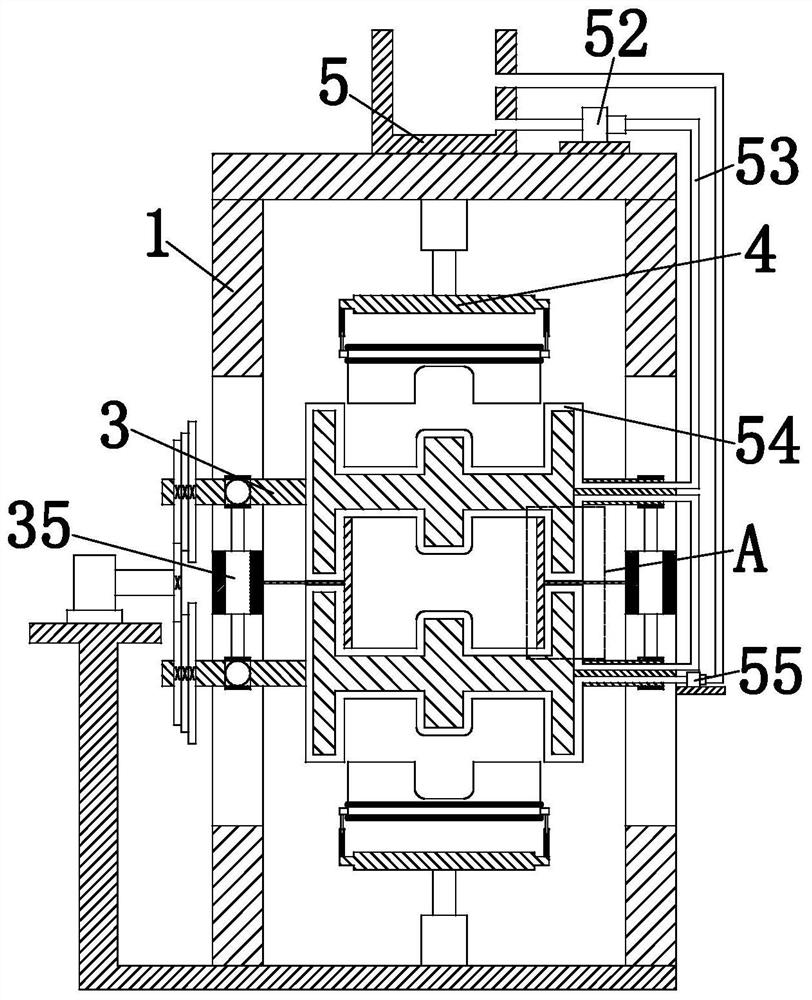

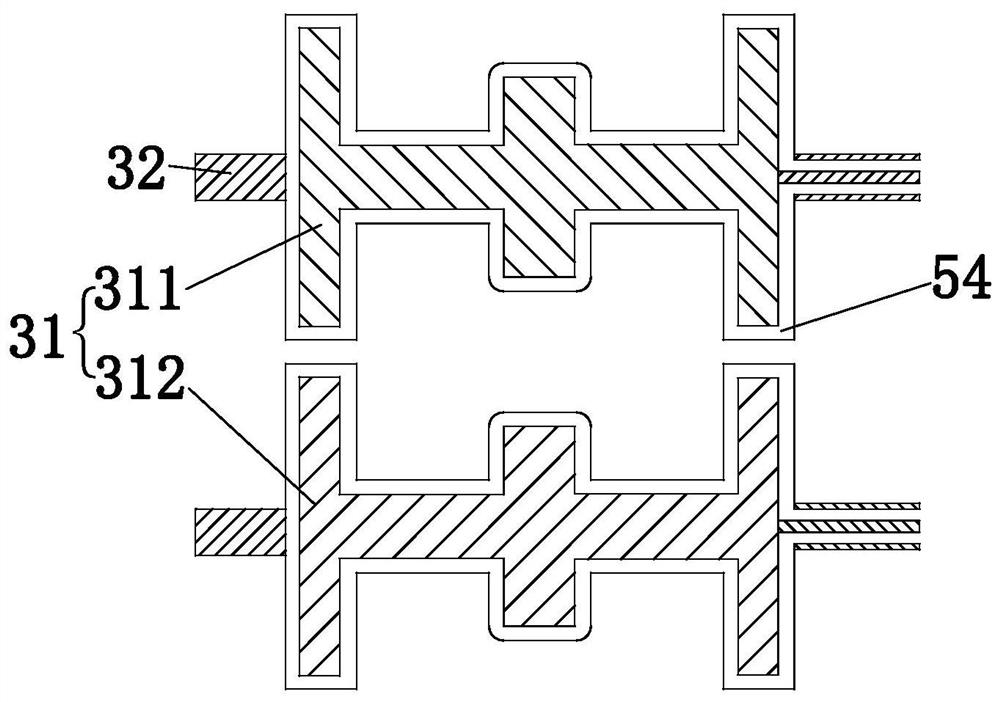

[0033] Such as Figure 1 to Figure 9 As shown, a rubber calender includes a frame body 1, a feeding device 2, a calendering device 3, a scraping device 4, a cooling device 5 and a discharge device 6, and the left side of the frame body 1 is provided with a feeding Device 2, a calendering device 3 is provided in the middle of the frame body 1, a scraper device 4 is installed on the upper and lower ends of the frame body 1, a cooling device 5 is installed at the front end of the frame body 1, and an outlet is placed on the right side of the frame body 1. Material device 6, wherein:

[0034] The feed device 2 includes a feed plate 21 and a feed cylinder 22, wherein the right end of the feed plate 21 is connected to the left side wall of the frame body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com