Beating-up mechanism of 736 type rapier loom

A rapier loom and beating-up technology, which is applied in the directions of looms, textiles, textiles and papermaking, can solve the problems of beating-up strength and durability that are difficult to meet the quality requirements of fabrics, and achieve the effect of high durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] The beating-up mechanism of the 736 type rapier loom includes a frame. Side plates 1 are arranged on both sides of the frame. The side plate 1 is provided with a cam hole 2 and a shaft hole 3. The position of the shaft hole 3 is higher than that of the cam hole 2. , and the cam hole 2 and the shaft hole 3 are arranged on both sides of the side plate 1 respectively.

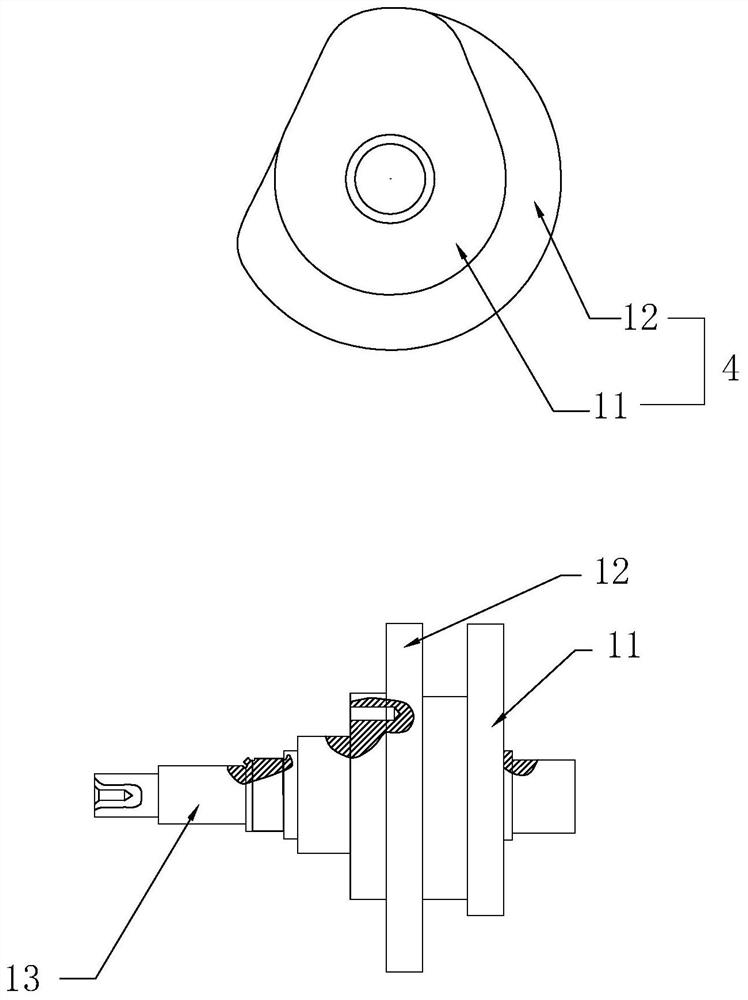

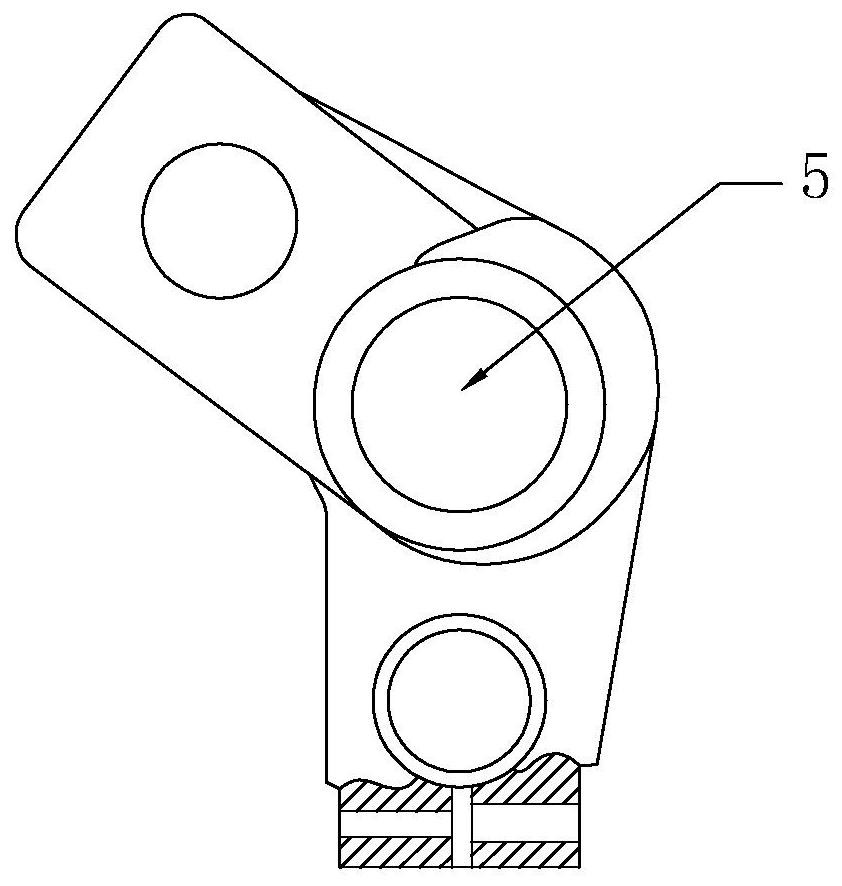

[0019] The cam hole 2 is provided with a conjugate cam 4 , and the shaft hole 3 is provided with a rocker shaft 5 . The conjugate cam 4 includes a main wheel 11 and a secondary wheel 12, a main shaft 13 is arranged between the primary and secondary wheels 12, and the maximum radius of the primary and secondary wheels 12 is consistent.

[0020] The shaft hole 3 includes an upper hole 8 and a lower hole 9 , and a connection cutout 10 is arranged between the upper hole 8 and the lower hole 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com