Sealing element structure and device of two-phase flow fine measurement device under high temperature and high pressure

A technology of high temperature and high pressure, measuring device, applied in the direction of measuring device, measuring device casing, thermometer parts, etc., to achieve the effect of compact structure, effective sealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

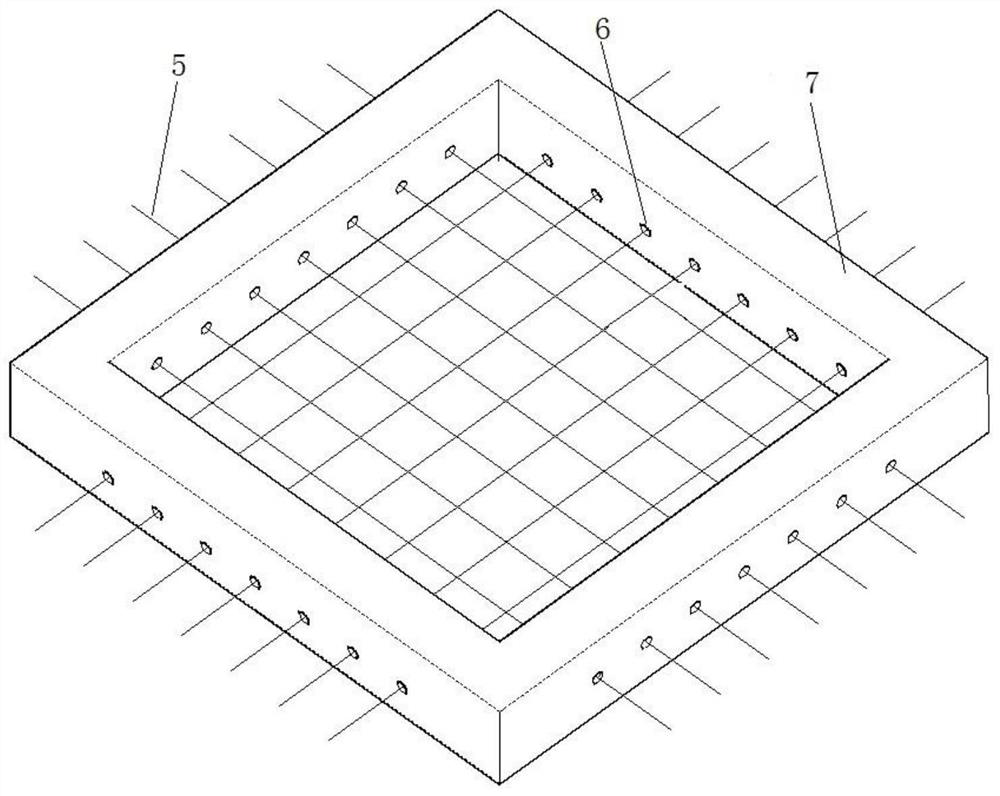

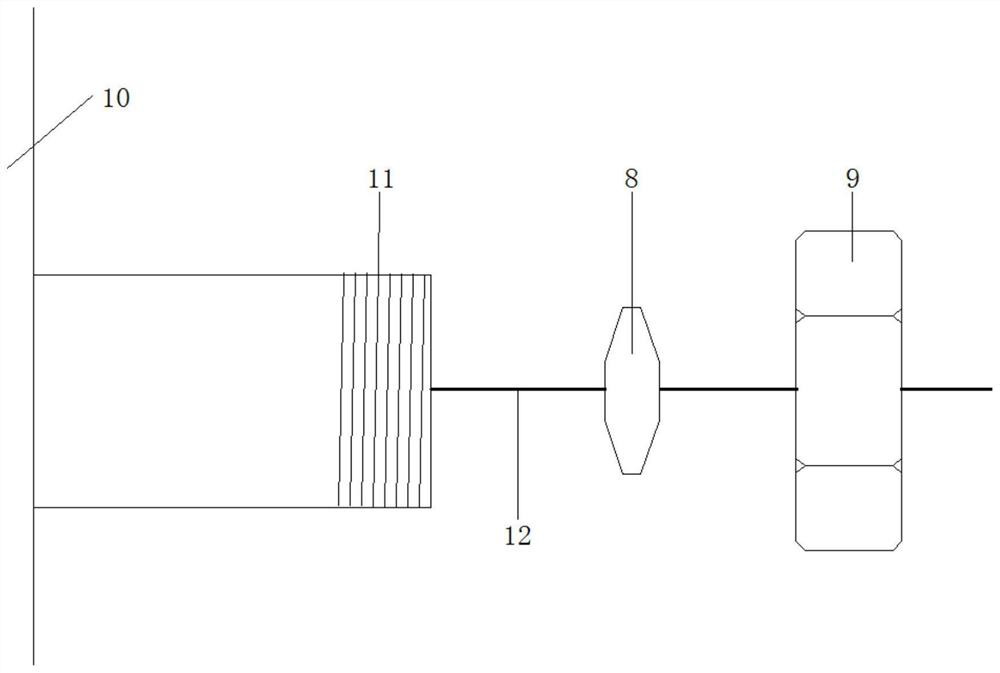

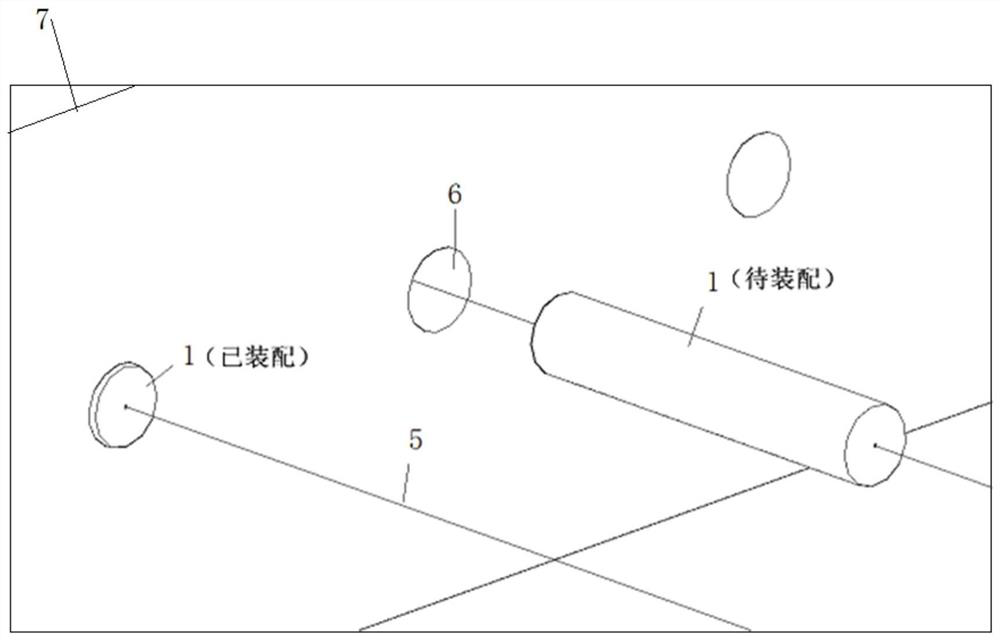

[0036] Such as Figures 1 to 6As shown in the present invention, a seal structure of a two-phase flow refinement measurement device under high temperature and high pressure conditions, the seal structure includes a seal body 1, the seal body 1 is a cylinder, and the seal body is axially A through hole 2 is concentrically provided, and the through hole 2 is used to set the electrode wire 5 of the two-phase flow fine measurement device; the seal body 1 is arranged on the through structure 6 on the substrate 7 of the two-phase flow fine measurement device Inside;

[0037] The seal body 1 is made of a metal with a large thermal expansion coefficient. In a cold state, the electrode wire 5 is passed through the through hole 2, and the seal structure is assembled on the substrate 7 of the two-phase flow refinement measurement device. In the penetrating structure 6, there is a first thermal expansion gap 3 between the through hole 2 and the electrode wire 5, and there is a gap betwee...

Embodiment 2

[0050] Such as Figure 1 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment provides a refined measurement device for two-phase flow under high temperature and high pressure conditions, such as Figure 6 As shown, it includes a substrate 7, the substrate 7 is a hollow square body, and several penetrating structures 6 are evenly arranged on the same horizontal plane around the sides of the substrate 7; it also includes an electrode wire 5, and the electrode wire 5 passes through the substrate 7 Upper left and right symmetrical penetrating structures 6, the electrode wires 5 pass through the front and rear symmetrical penetrating structures 6 on the substrate 7; the distance between adjacent electrode wires 5 is 1 mm to 2 mm;

[0051] It also includes a seal structure of a two-phase flow refinement measurement device under high temperature and high pressure conditions in Example 1, the seal structure is assembled in each of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com