Dummy portion removing unit and dummy portion removing method using dummy portion removing unit

A technology for dummy parts and components, which can be applied to electrical components, glass manufacturing equipment, glass cutting devices, etc., and can solve problems such as residual adhesion state and dummy parts falling to undesired places

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

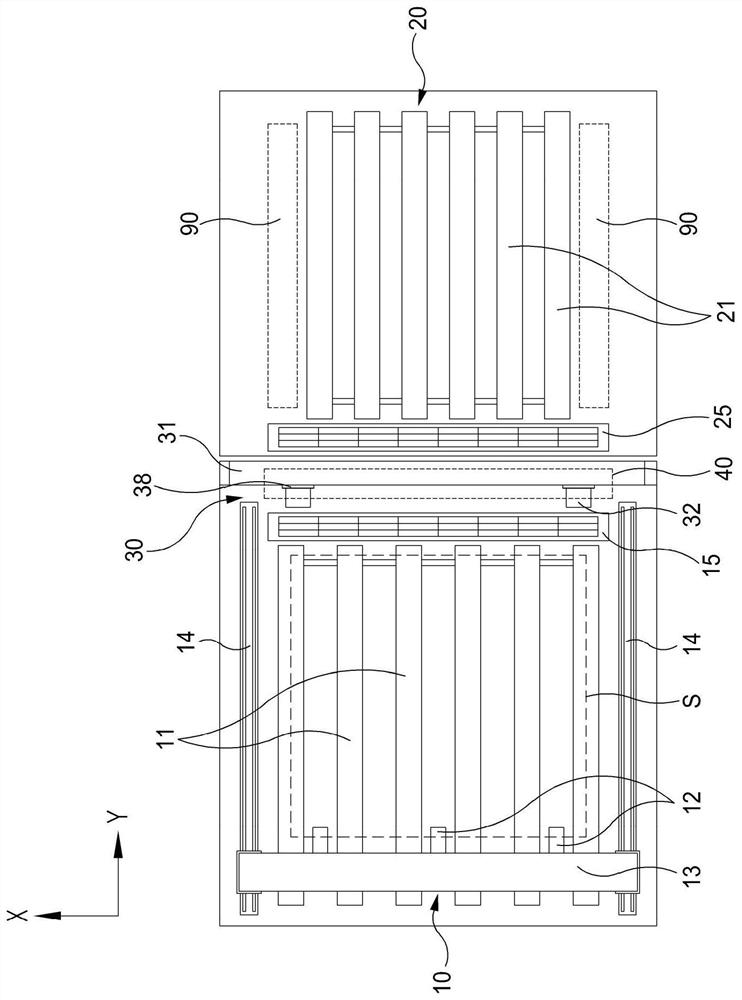

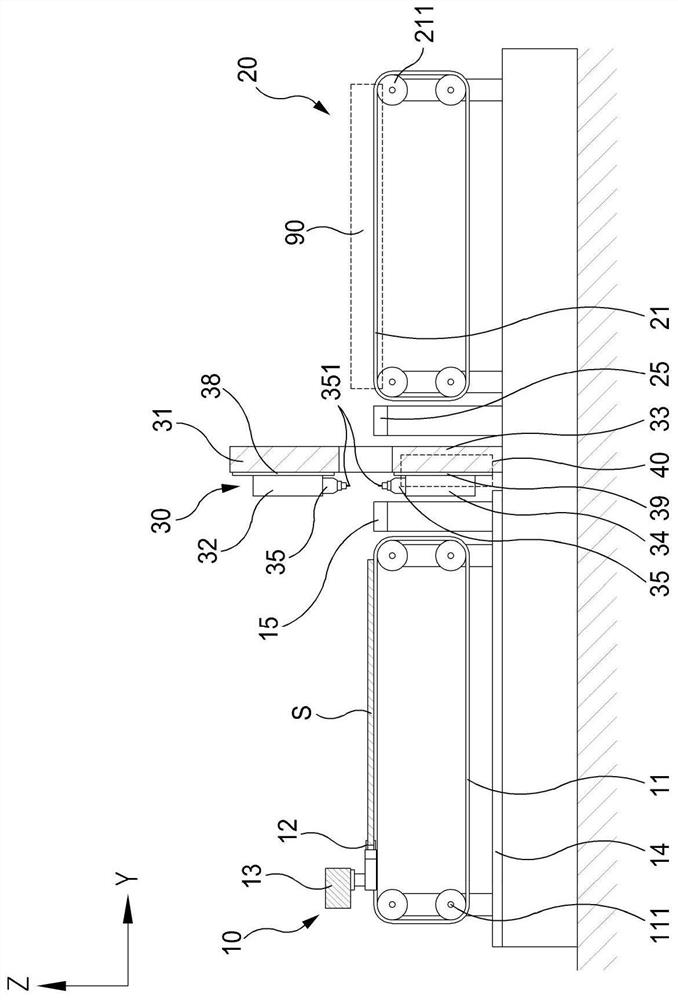

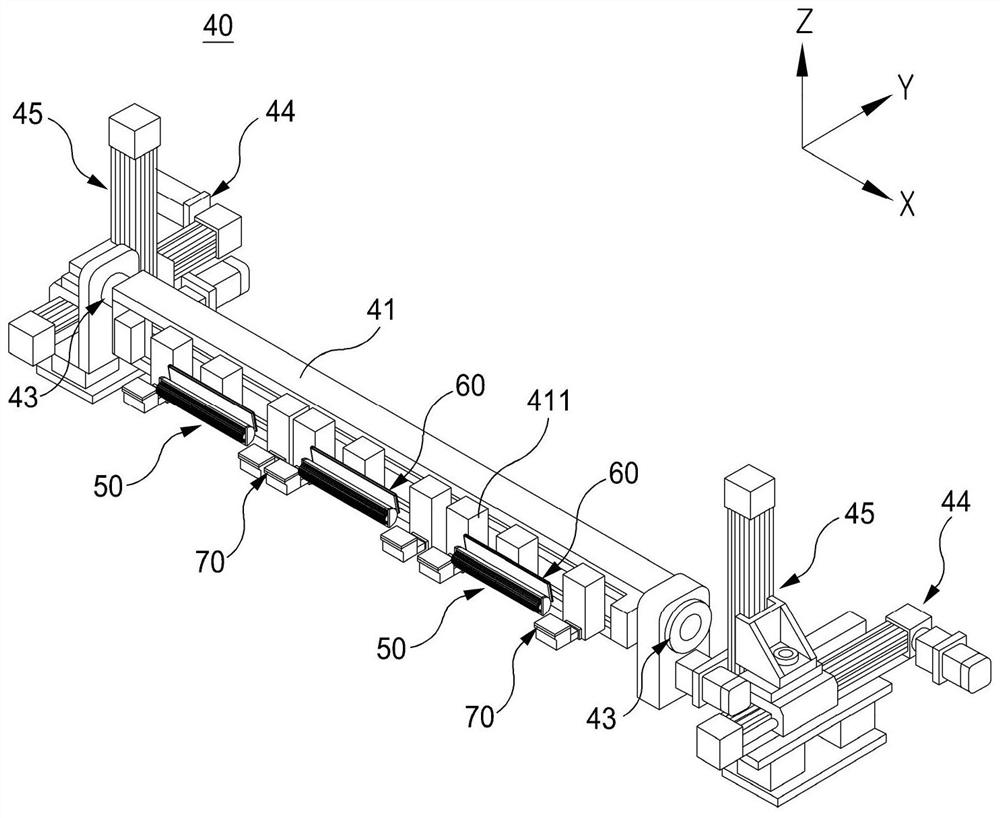

[0026] Hereinafter, a dummy portion removing unit and a dummy portion removing method using the dummy portion removing unit according to the present invention will be described with reference to the drawings.

[0027] First, a substrate dicing apparatus provided with a dummy portion removing unit according to an embodiment of the present invention will be described. An object to be cut by the substrate cutting device may be a bonded substrate constituted by bonding the first panel and the second panel. For example, the first panel may include thin film transistors, and the second panel may include color filters. On the contrary, the first panel may include color filters, and the second panel may include thin film transistors. In the figure, the first panel is located at the top and the second panel is located at the bottom, but the present invention is not limited to the orientation of the first panel and the second panel.

[0028] Hereinafter, the bonded substrate is simply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com