Horizontal paper inserting machine for production coil

A paper insertion machine and horizontal technology, applied in the field of horizontal paper insertion machines, can solve the problems of large moving space, inconvenient placement of mobile equipment, and difficult operation of stator cores, etc., to achieve convenient positioning of stator cores and accurate linkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

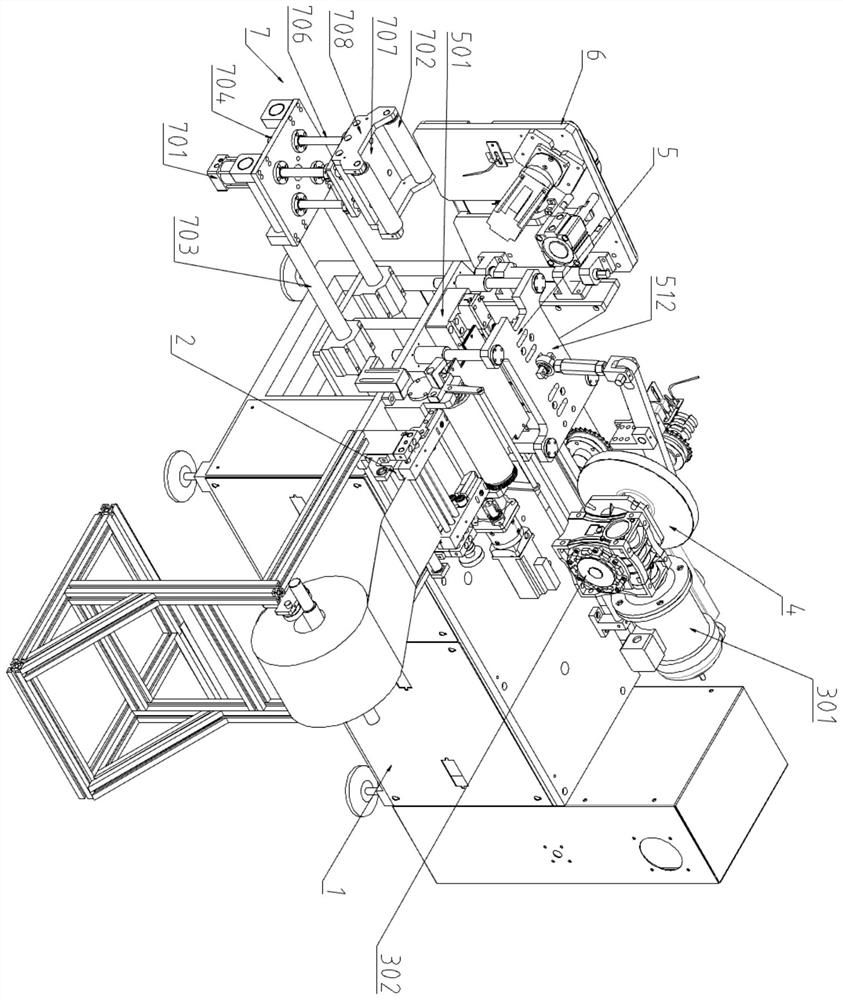

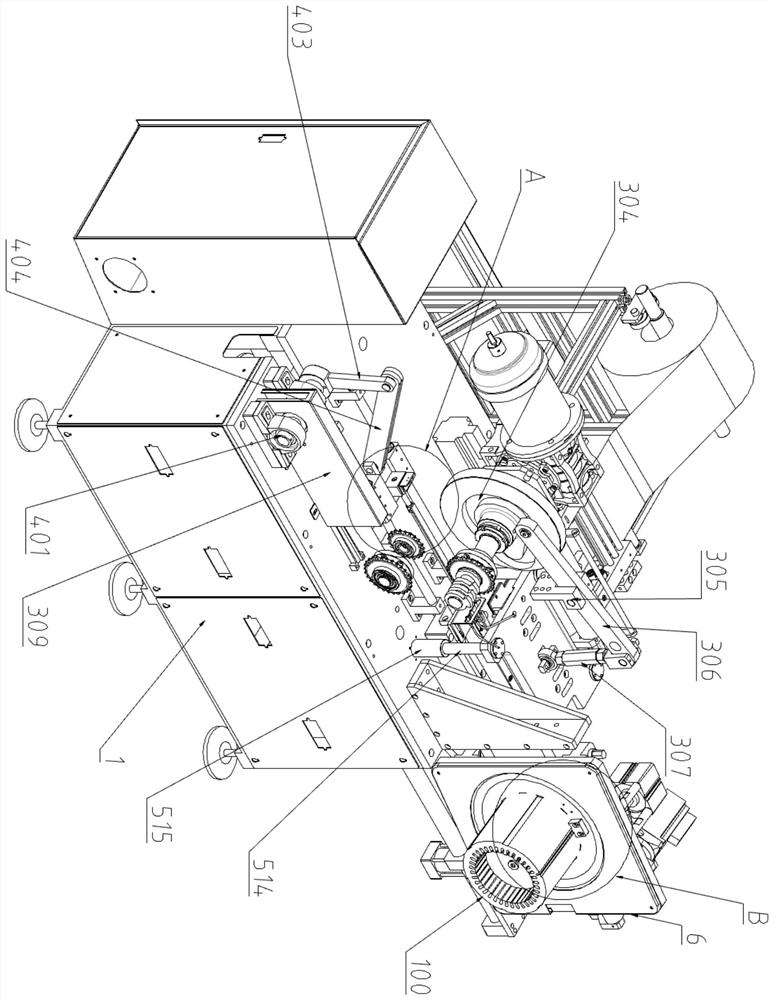

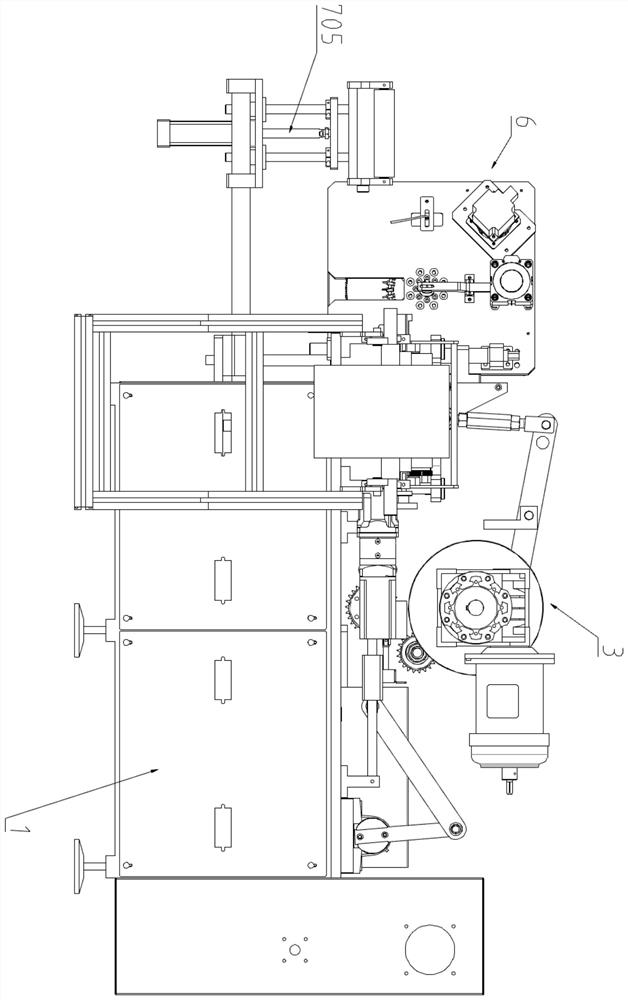

[0030] Such as Figure 1-12 As shown, a horizontal paper inserting machine for producing coils includes a frame 1, a rotating assembly 6 supported on the frame 1 to support the stator core 100 and drive the rotation of the stator core 100, and supported on the machine The hemming assembly 2 on the frame 1 is used to fold both sides of the insulating paper 200 inwardly, the forming assembly 5 supported on the frame 1 is used to cut and form the folded insulating paper 200, and the forming assembly 5 is supported on the frame 1 is used to push the insulating paper 200 formed by the molding assembly 5 into the wire groove 101 of the stator core 100 on the rotating assembly 6, and alternately drive the molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com