Cartridge filter suitable for filtering soft impurities and filtering system

A technology of impurity filtration and filtration system, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problem of difficulty in removing soft impurities, improve coating uniformity, avoid air bubbles, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

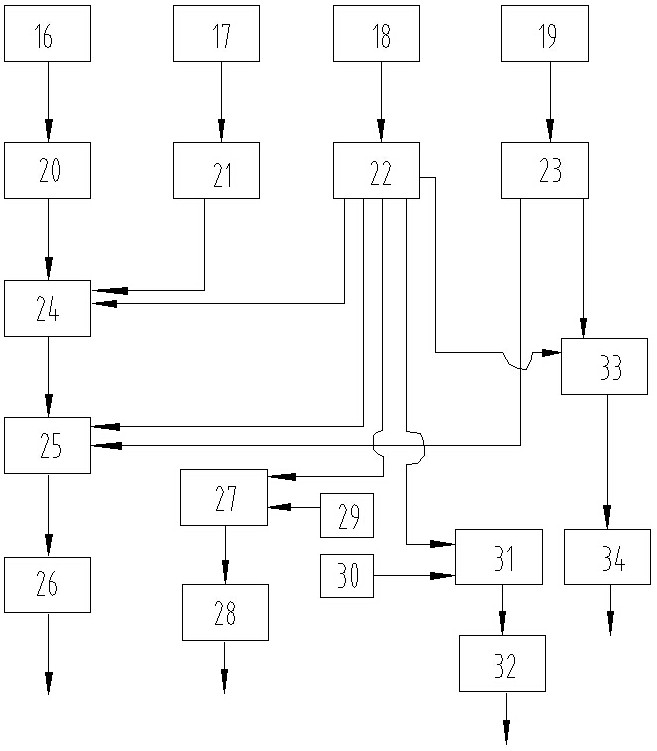

[0029] Elastic filter element among the present invention and rigid filter element are all commercially available products, and silver solution is silver nitrate solution, and brine is halide solution, and silver solution among the present invention, brine, true solution supplementary agent, latex supplementary agent , anti-halation dye and matting agent are common solutions in the film production process, and the chemical reactions that take place in the present invention are all common chemical reactions in the art.

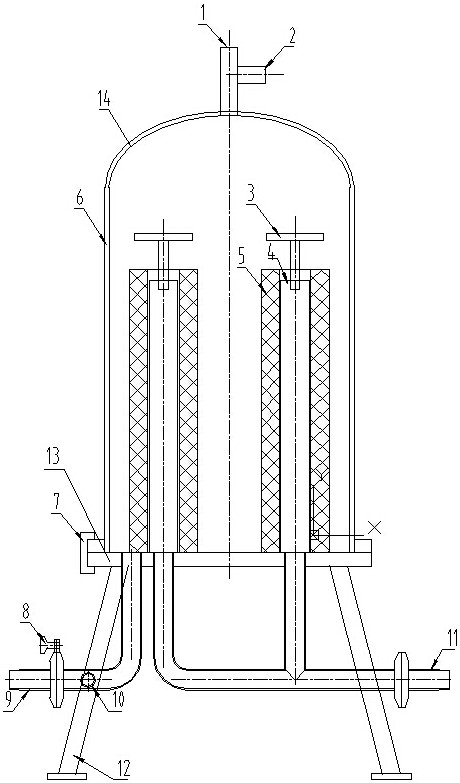

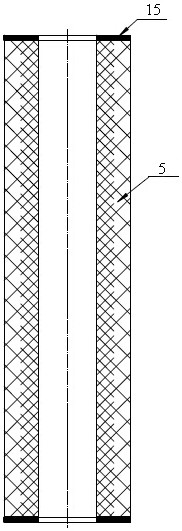

[0030] as attached Figure 1-2 As shown, the cartridge filter suitable for filtering soft impurities includes a bracket 12, the cylinder body 6 is fixed on the bracket 12, the cylinder bottom 13 is detachably fixed on the bottom of the cylinder body 6 through the filter cartridge chuck 7, and the cylinder top 14 is detachable fixed on the top of cylinder 6, pressure gauge port 1 and exhaust port 2 are arranged on cylinder top 14, center rod 4 is fixed inside cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com