Manufacturing process for bunk bed

A manufacturing process, bunk bed technology, applied in the direction of manufacturing tools, woodworking lathes, wood processing equipment, etc., can solve the problems of high pressure on bunk beds, wood fracture, furniture damage, etc., to increase the surface area and reduce wood warping , the effect of slowing down the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-4 The application is described in further detail.

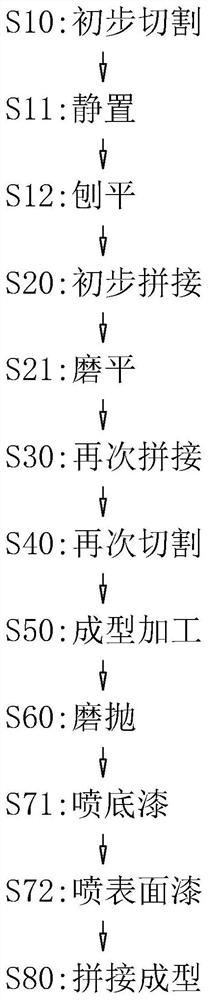

[0044] The embodiment of the present application discloses a manufacturing process of a bunk bed. refer to figure 1 , the manufacturing process of bunk bed comprises the following steps:

[0045] S10: Preliminary cutting;

[0046] S11: stand still;

[0047] S12: planing;

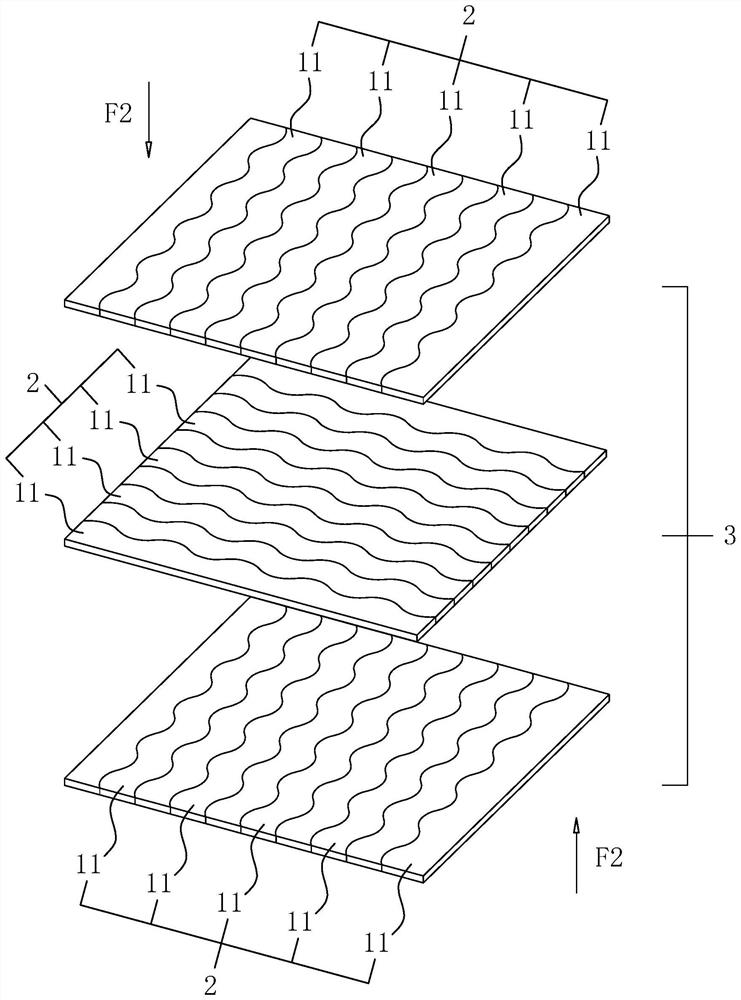

[0048] S20: preliminary bonding;

[0049] S21: grind flat;

[0050] S30: bonding again;

[0051] S40: cutting again;

[0052] S50: forming processing;

[0053] S60: grinding and polishing;

[0054] S71: spray primer;

[0055] S72: Spray surface paint;

[0056] S80: Stitching and molding.

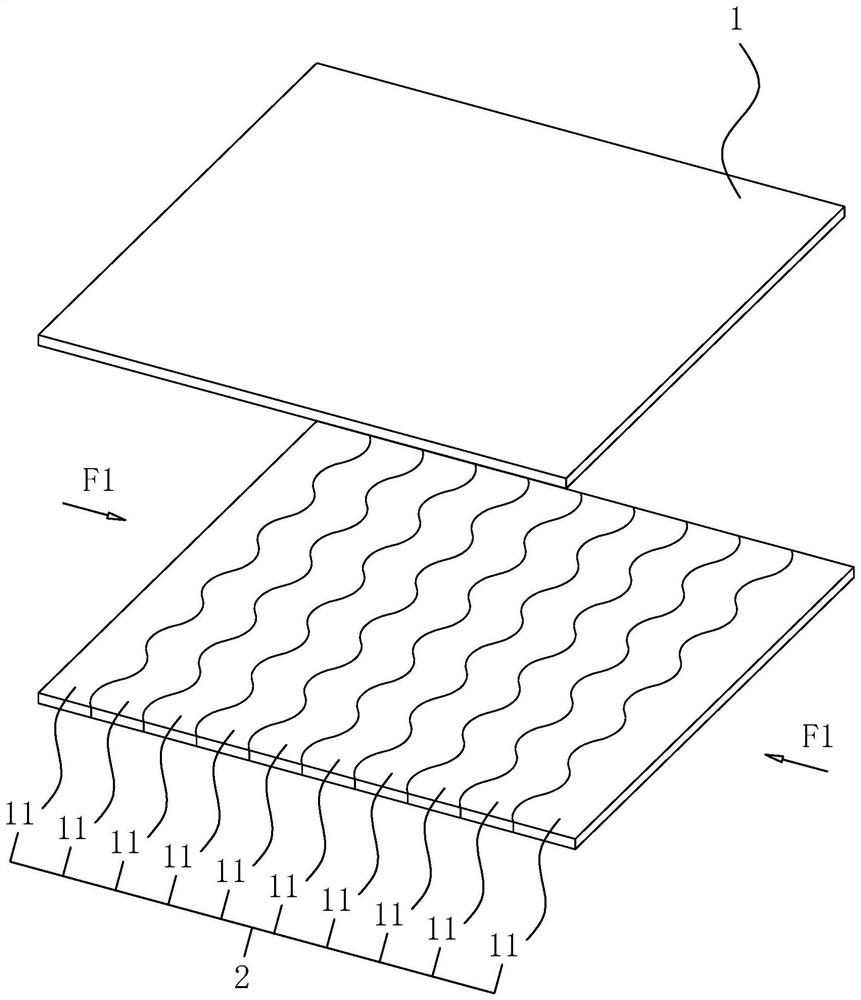

[0057] refer to figure 2 , S10: Preliminary cutting; cutting the heat-treated log 1 into wooden strips 11; when cutting, cutting the heat-treated log 1 into wooden strips 11 with a wire saw, releasing the internal stress in the log 1 by cutting; Moreover, the cutting surface of the wooden strip 11 is wavy or zigzag ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap