A milk tea cup automatic handling system

A technology of handling system and milk tea cup, which is applied in the direction of transportation and packaging, packaging, conveyor objects, etc. It can solve the problems of complex structure of clamping mechanism, increase of manufacturing cost and difficulty of debugging of automatic milk tea machine, and achieve simple structure and cost saving The effect of low expenditure and manufacturing cost

Active Publication Date: 2022-01-28

广州酷库智能科技有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the structure of the above-mentioned clamping mechanism is complicated, and it will increase the manufacturing cost and debugging difficulty of the automatic milk tea machine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

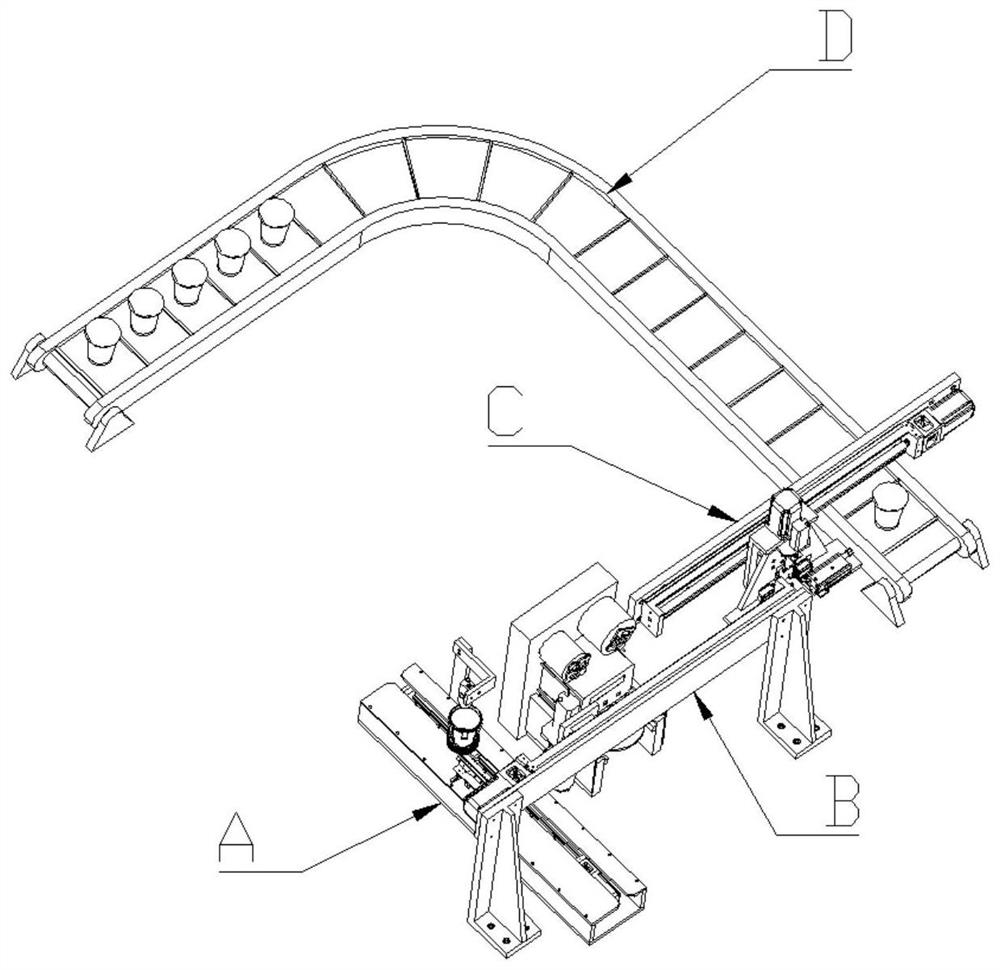

[0076]This embodiment is different from Embodiment 1 in that: the milk tea cup conveying driving mechanism includes a driving cylinder, the cylinder body of which is installed on the first frame 1a, and the telescopic rod of the driving cylinder is connected to the conveying seat 3- 1 connection.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

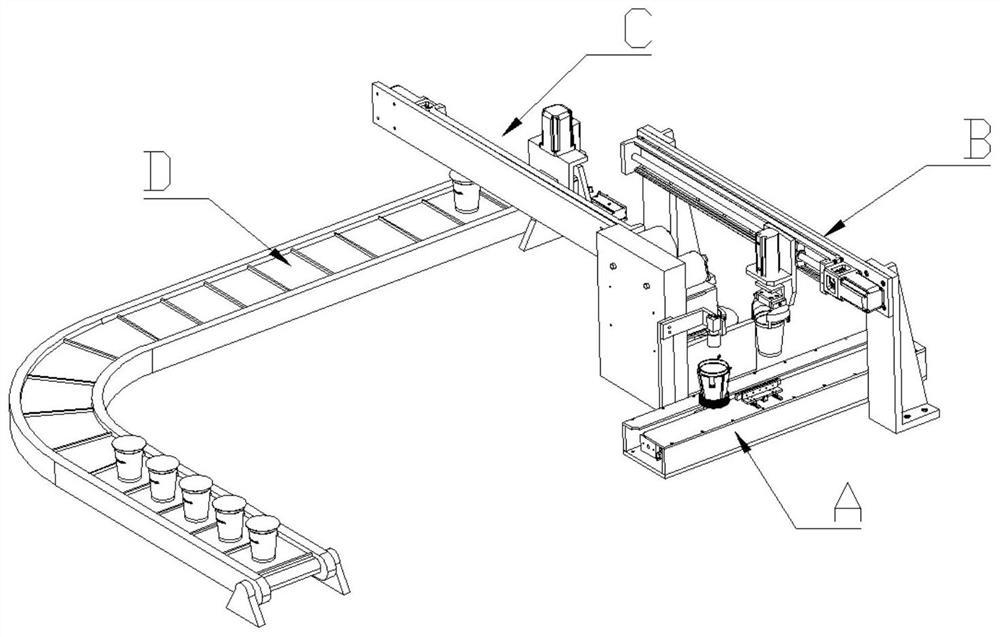

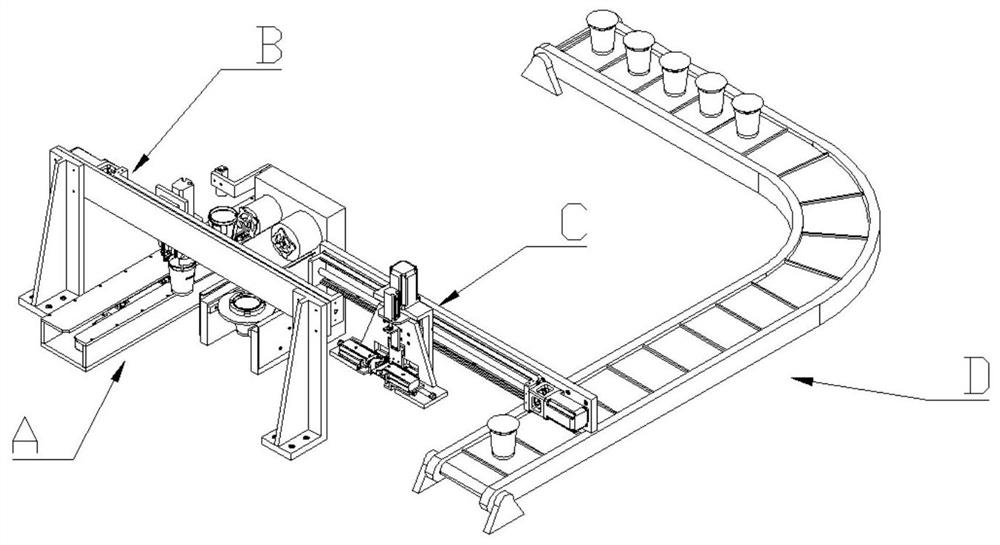

The invention discloses an automatic milk tea cup conveying system, comprising a first conveying device for conveying the sent milk tea cups to a cupping station, and a first conveying device for conveying the milk tea cups in the first conveying device to a capping device The second conveying device, the finished product conveying device for conveying the finished milk tea cups, and the third conveying device for transferring the milk tea cups in the second conveying device to the finished product conveying device. The milk tea cup automatic handling system of the present invention can be adapted to transport different types of milk tea cups, and can carry out self-adaptive clamping on the milk tea cup when the milk tea cup is filled with milk tea, thereby ensuring that the milk tea cup does not tilt during the process of filling the milk tea. In addition, The milk tea automatic conveying system has the advantages of fast conveying speed and high conveying efficiency.

Description

technical field [0001] The invention relates to a milk tea machine, in particular to an automatic milk tea cup conveying system. Background technique [0002] The existing tea shops are all made by hand, but the cost of labor is increasing day by day, and the sales time is very limited by the working hours of the employees. With the advent of the era of artificial intelligence, robots are becoming more and more popular, but there is no robot milk tea machine on the market at present. The current milk tea production is generally made on-site by employees of milk tea shops. The current milk tea production steps mainly include water agent, The steps of adding powder, sauce, stirring, milk cap, and cups all need to be completed by the staff of the milk tea shop, but these repetitive mechanical tasks can be solved by robots. Moreover, during the production process, it is easy to make mistakes in adding raw materials, uneven mixing, and problems such as unhygienic processing by s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B43/42B65B43/46B65G47/91B65G47/90

CPCB65B43/42B65B43/46B65G47/91B65G47/912B65G47/90B65G47/901B65G2201/0235

Inventor 陈卫华

Owner 广州酷库智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com