A kind of vial automatic filling device

A filling device and vial technology, applied in bottle filling, packaging, bottling machines, etc., can solve the problems of unguaranteed product quality consistency, product pollution, low production efficiency, etc., and achieve structural movement time saving and automation High degree of effect of improving clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

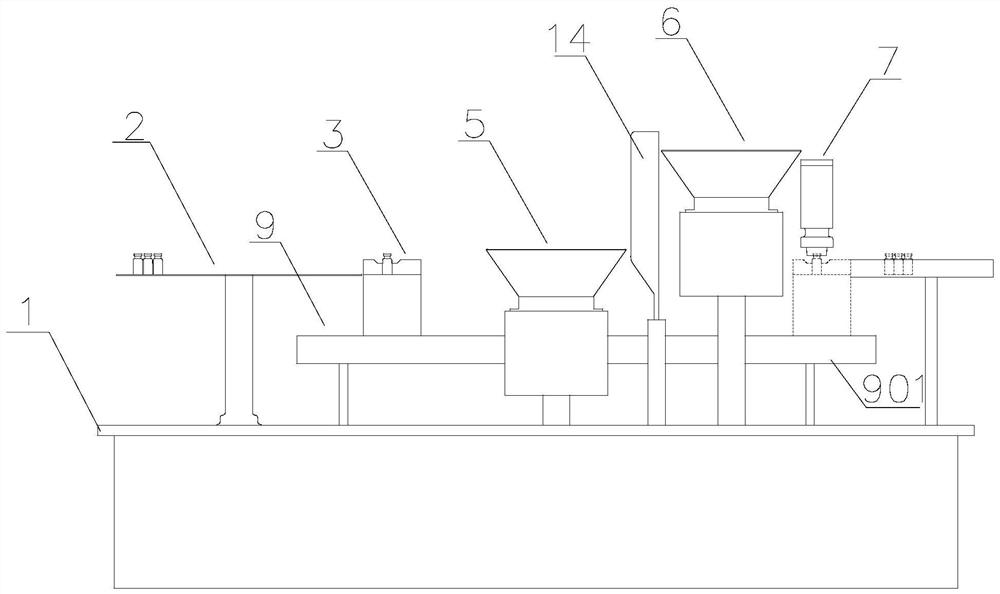

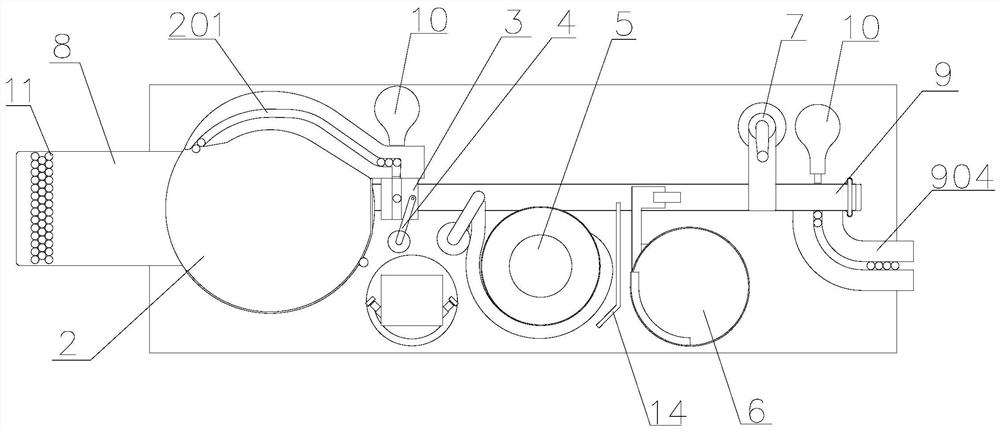

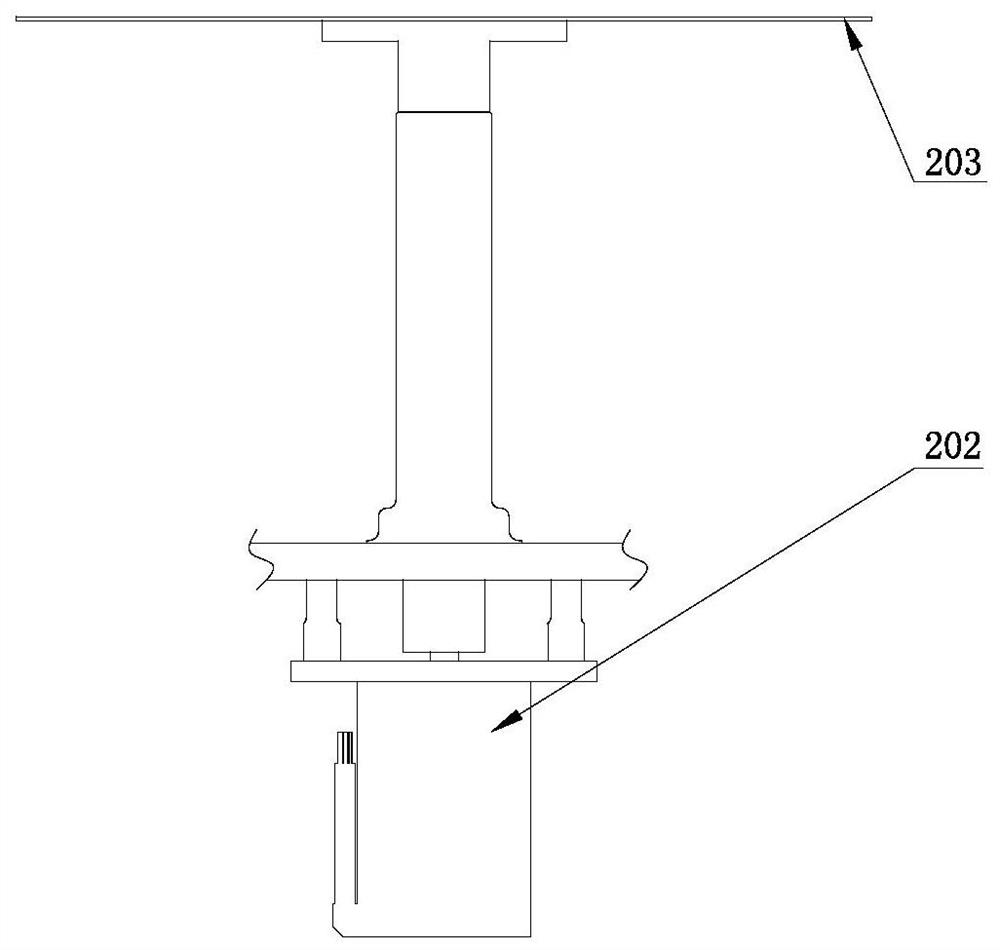

[0058] like Figure 1-2 Shown: an automatic filling device for vials, comprising: a platen 1, a rotary bottle unscrambler 2, a bottle clamping unit 3, a filling unit 4, a stoppering unit 5, An aluminum cap scraping unit 6 and a capping unit 7, a bottle feeding pallet 8 arranged at the front end of the rotary unscrambling table and docked with the rotary bottle unscrambling table, and a conveying unit 9 provided on the table for conveying vials 11. A partition 14 is arranged between the plugging unit and the aluminum cover scraping unit on the platen.

[0059] The working principle of the device in this embodiment is roughly as follows: the bottle feeding pallet is controlled by supporting equipment on the production line, and the vials are pushed into the rotary bottle unscrambling table, and the rotary bottle unscrambling table rotates (clockwise) to drive the vials into the guide groove and always along the guide The groove is transported to the joint between the guide groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com