On-line non-contact monitoring method and device for curing state of coating

A curing state and monitoring device technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, instruments, analysis materials, etc., can solve problems such as probe detection error and damaged probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

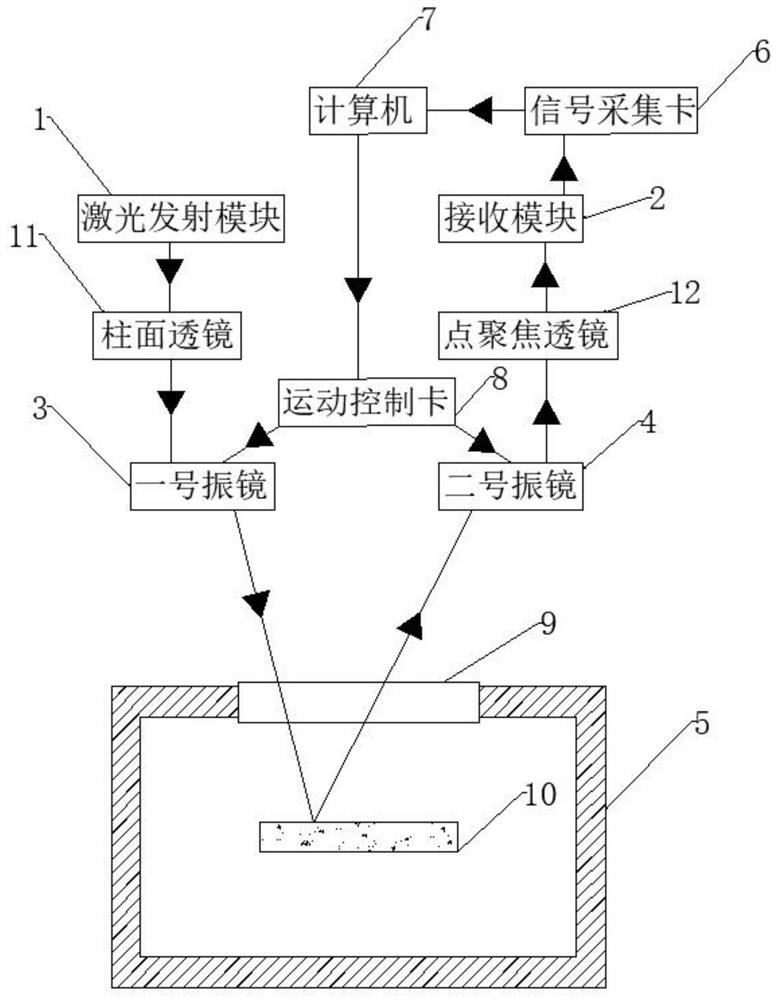

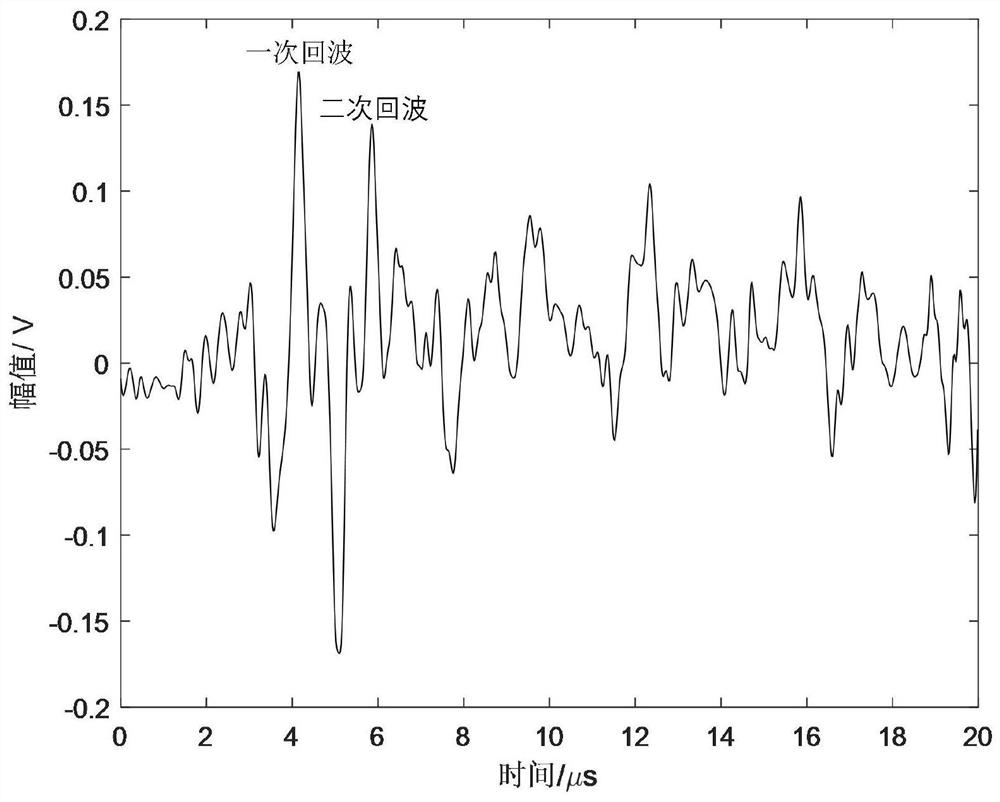

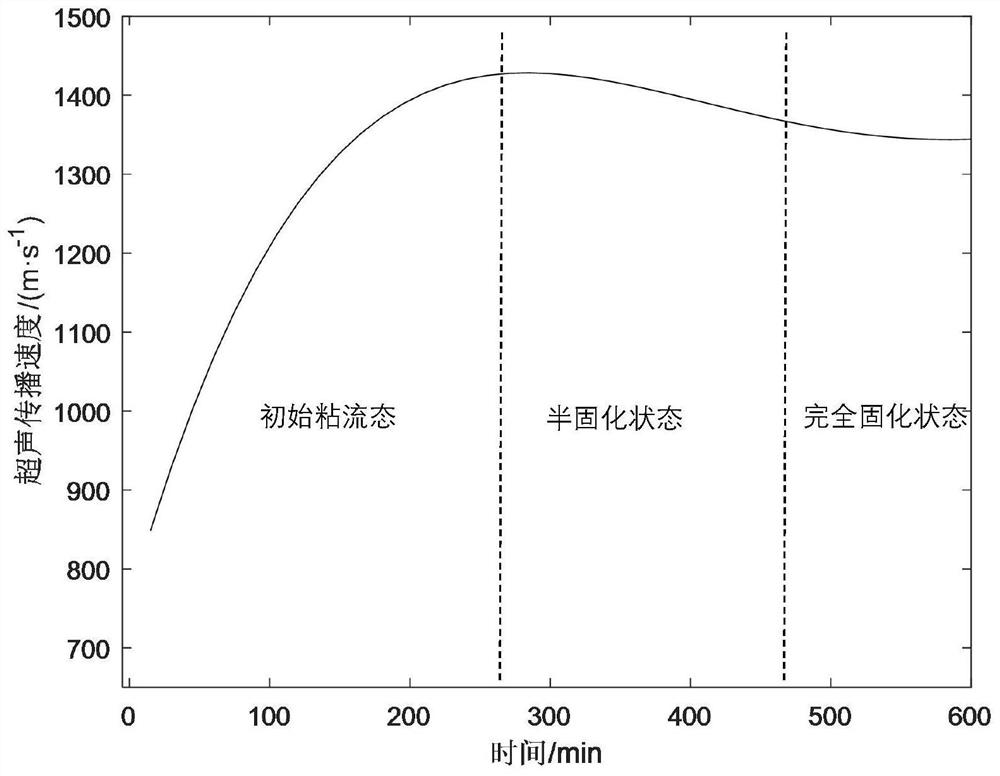

[0021] Such as figure 1 As shown, an online non-contact monitoring method of coating curing state, according to the curing process requirements of the curing material, the material 10 to be cured is placed in a suitable constant temperature environment, and the excitation laser is emitted to the material 10 to be cured. The surface of the material 10 is excited to generate ultrasonic waves and propagate on the surface and inside of the material 10 to be cured, emit and receive laser light to the material 10 to be cured, receive the ultrasonic waves on the surface of the material 10 to be cured by receiving the laser, and analyze the amplitude and arrival time of the received ultrasonic waves, And using the amplitude and arrival time of the ultrasonic wave to calculate the ultrasonic sound velocity and the change of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com