A special optical mold and its assembly process and use method

An optical and mold technology, applied in the optical field, can solve the problems of high finished product, unfavorable filter selector mold popularization, and inability to control the angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

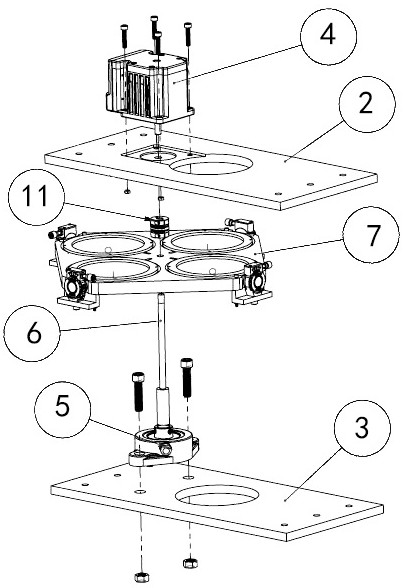

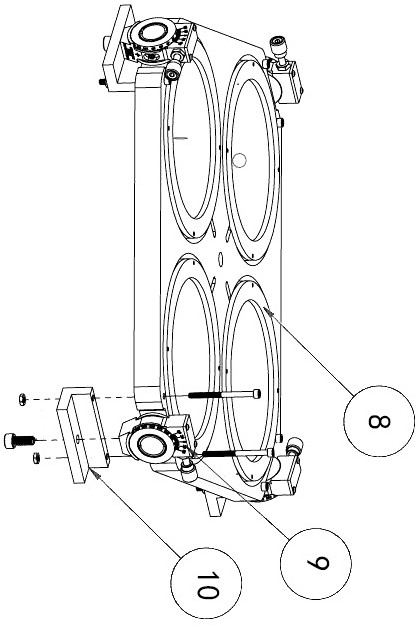

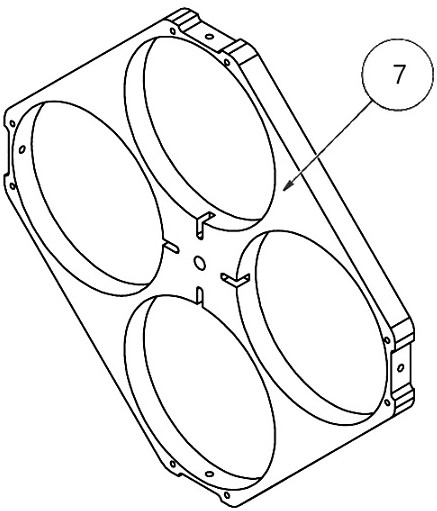

[0028] The present invention will be further described below in conjunction with specific examples.

[0029] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention. The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The filter mechanism is an important component such as an area array staring camera. It needs to switch filters frequently during the entire life cycle of the camera in orbit to cooperate with the multi-spectral imaging work of the whole machine, and this part is usually a single point of failure of the camera. link. Therefore, ensuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com