Lens driving mechanism, lens driving device, photographic device, and electronic equipment

A technology of lens driving and driving frame, which is applied in the fields of lens driving device, camera device, electronic equipment and lens driving mechanism, can solve the problems such as the non-functioning of the anti-shake motor and the falling off of balls, so as to improve the convenience of assembly and improve the anti-shake performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

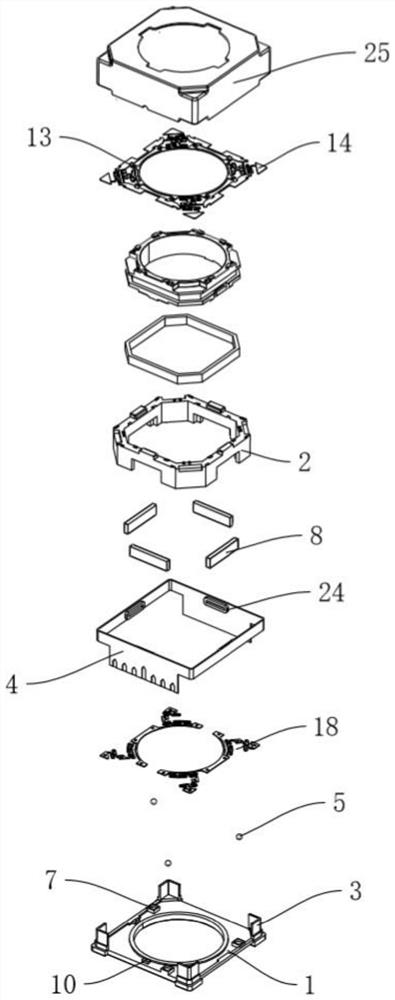

[0030] Embodiment 1: as Figure 1 to Figure 6 As shown, an anti-shake structure proposed by the present invention includes a housing 25, a base 1, and a frame body 2 connected to the driving body. A moving assembly and a driving assembly are arranged between the base 1 and the frame body 2. Four Brackets 3 are integrally formed at corner positions, and FPC boards 4 are connected between the four brackets 3 .

[0031] The moving assembly includes three balls 5 arranged between the base 1 and the frame body 2, an accommodating groove 6 set on the bottom surface of the frame body 2 and accommodating the balls 5, and a movable groove set on the base 1 for the relative movement of the balls 5 7. The diameter of the movable groove 7 is larger than that of the ball 5 , and the ball 5 is movable relative to the movable groove 7 . The frame body 2 is stably supported by three balls 5, and the balls 5 move in the movable groove 7 to facilitate the translation of the frame body 2 relati...

Embodiment 2

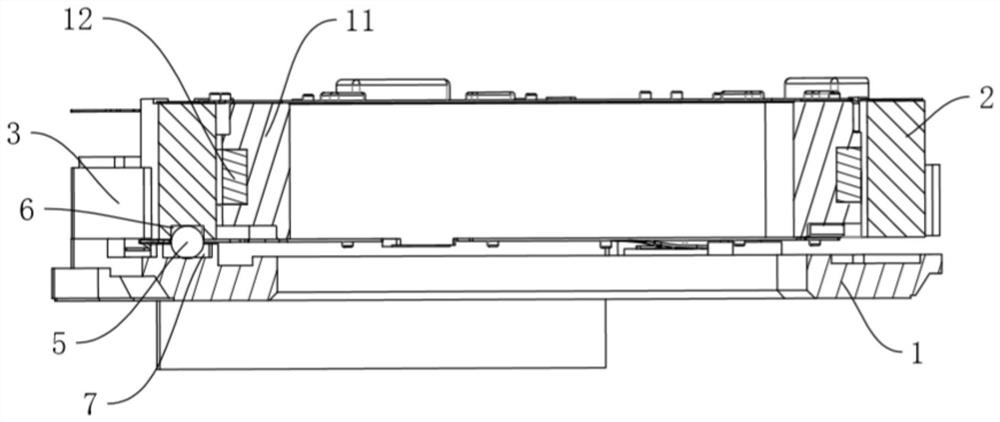

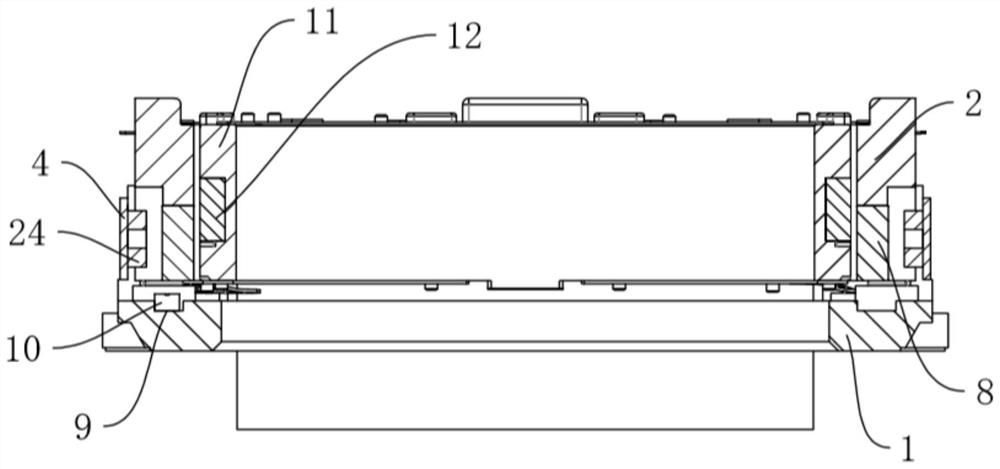

[0036] Embodiment 2: a kind of lens driving device, such as Figure 7 As shown, it has the lens driving mechanism described in Embodiment 1, and also includes a driving body connected to the frame body 2. The driving body includes a carrier 11 that is arranged in the frame body 2 and can move relative to the frame body 2, and is arranged on the carrier body 11. And drive coils 12 corresponding to the four magnets 8 . The inner grouping 13 of the upper spring is arranged between the end of the carrier 11 facing away from the base 1 and the frame body 2 , and the inner fixing part of the lower spring is connected to the end of the carrier 11 facing the base 1 .

Embodiment 3

[0037] Embodiment 3: a photographic device having the lens driving device described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com