Design method of edge pressing device for drawing forming of continuous variable cross-section plate

A blankholder and panel technology, which is applied in the field of blankholders, can solve problems such as cracking of stepped compression rings, and wrinkling of blankholders in contact with blanks, so as to achieve the effect of reducing cracking and eliminating wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principle of the present invention and its implementation are further illustrated below by way of examples and with reference to the accompanying drawings.

[0014] Automobile B-pillar is one of the typical thin-walled structural parts. The middle part of the traditional B-pillar adopts a reinforced plate to obtain higher strength. Variable section plate forming automobile B-pillar adopts increased thickness instead of reinforcement plate, which has lower cost and higher performance. According to the forming characteristics of the B-pillar, deep-drawing takes place in the width direction, and the resistance is provided by the blanking method on both sides; the two ends in the length direction are constrained by boundary conditions and receive greater resistance, which can be converted to the blanking method to provide. For this reason, the B-pillar can be abstracted as a rectangular box-shaped piece.

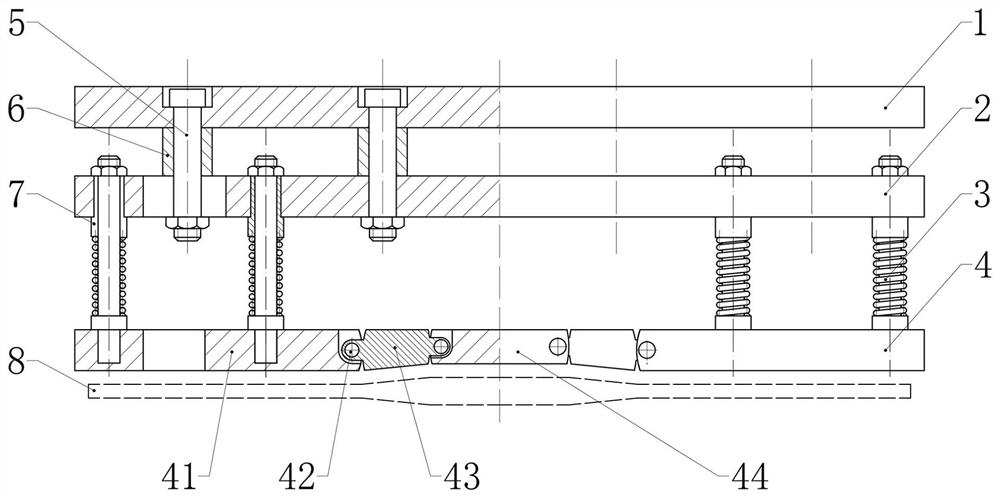

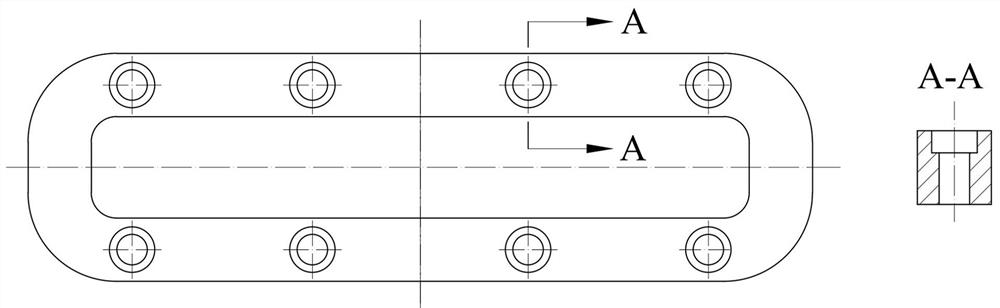

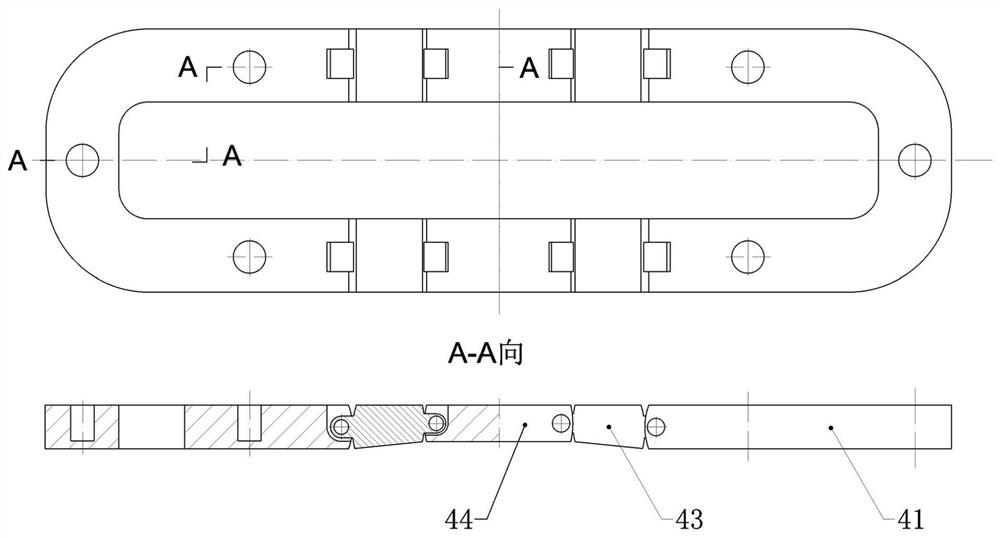

[0015] The structure of the edge-holding device for deep-drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com