Single-roller rectification device during proceeding

A deviation correction device and a technology between travels, applied in the fields of coating material processing machinery, printing and packaging, it can solve the problems of material film scrapping, material film wrinkling, and failure to meet the requirements of the machine, and achieves the advantages of convenient operation, wrinkle elimination, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The invention provides a single-roller deviation correction device during travel, which includes a moving track mechanism and a material film detection mechanism,

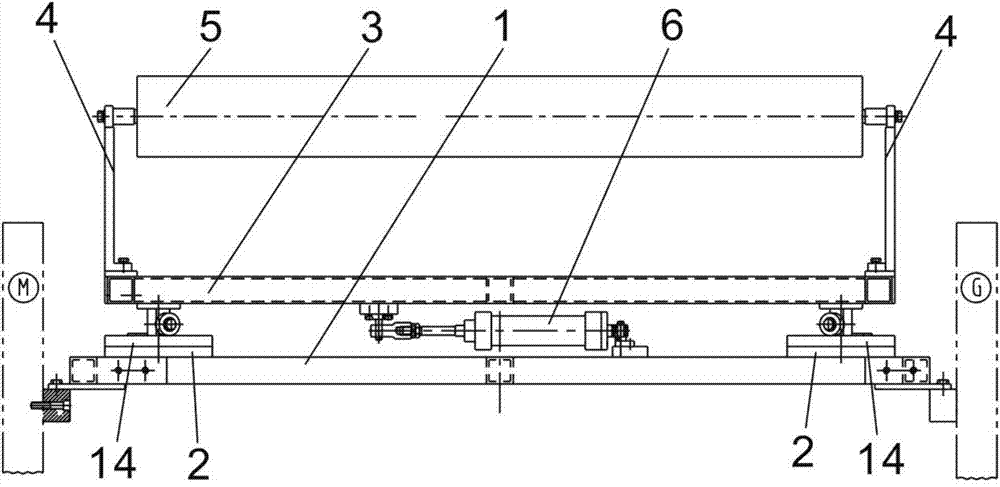

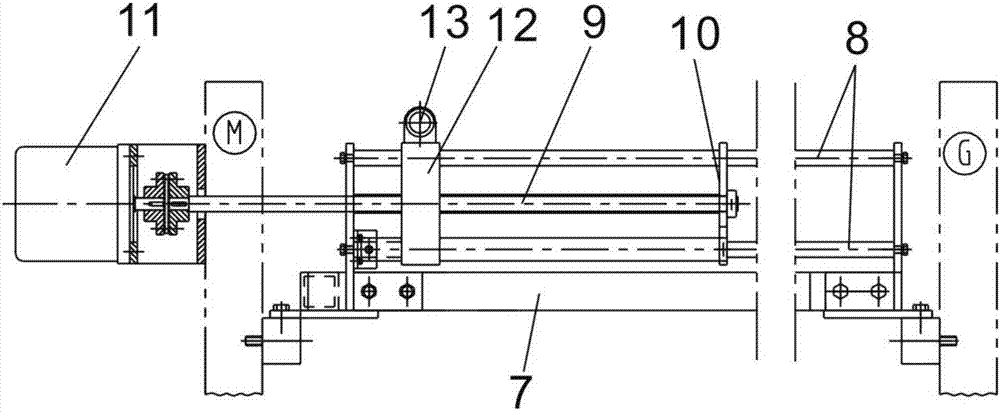

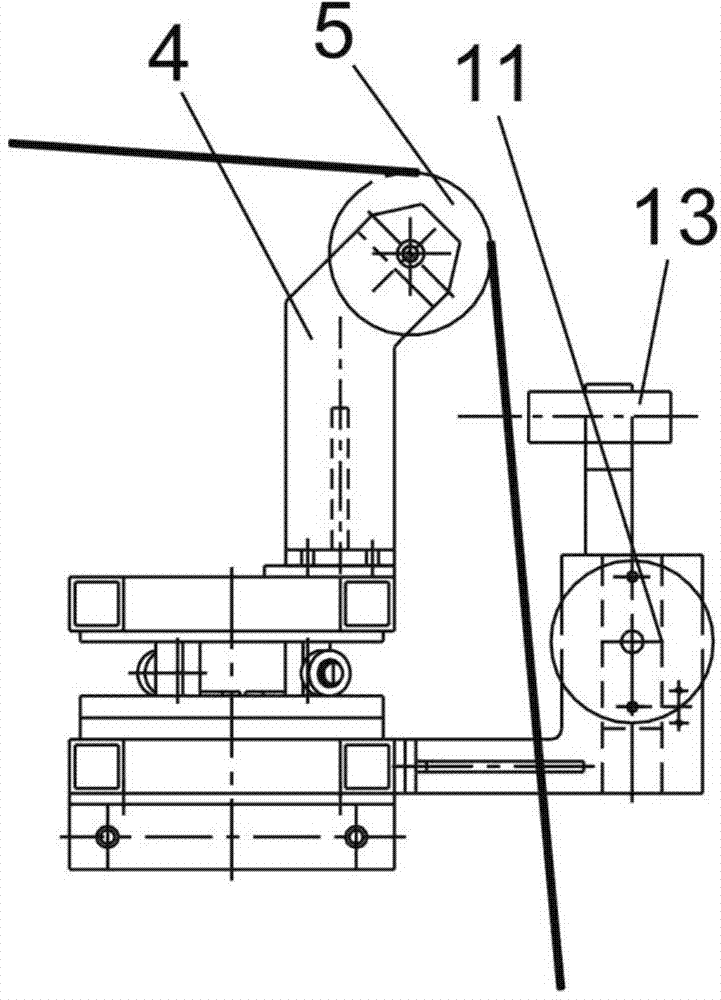

[0038] Such as figure 1 As shown, the mobile track mechanism includes a fixed lower bracket 1 fixed on the frame, and a connecting plate 2 is fixedly connected to both ends of the upper surface of the fixed lower bracket 1, and the two connecting plates 2 are connected to the movable upper bracket 3 through the deflection mechanism. connected, the deflection mechanism is located at both ends of the lower surface of the movable upper bracket 3, a pair of guide roller brackets 4 are fixed symmetrically on both ends of the upper surface of the movable upper bracket 3, and a deviation-correcting guide roller 5 is arranged between the two guide roller brackets 4, A pusher 6 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical distance | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com