Automatic corrugating machine using hot-melt adhesive

A technology of corrugated composite machine and hot melt adhesive, applied in the direction of mechanical processing/deformation, layered products, etc., can solve the problems of difficult maintenance, many waste products, high composite cost, etc., achieve easy operation and maintenance, reduce manufacturing costs, and overcome misalignment uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

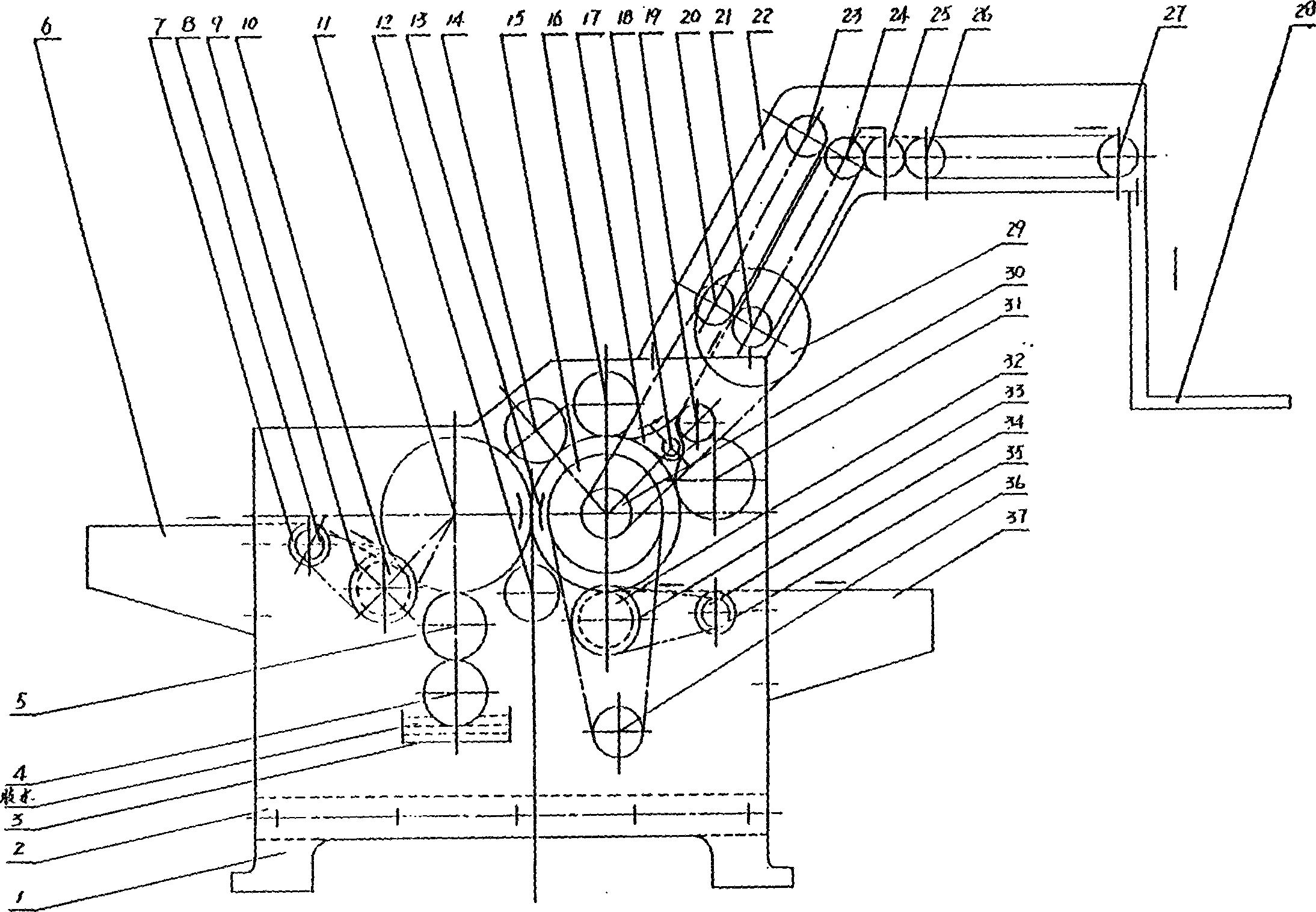

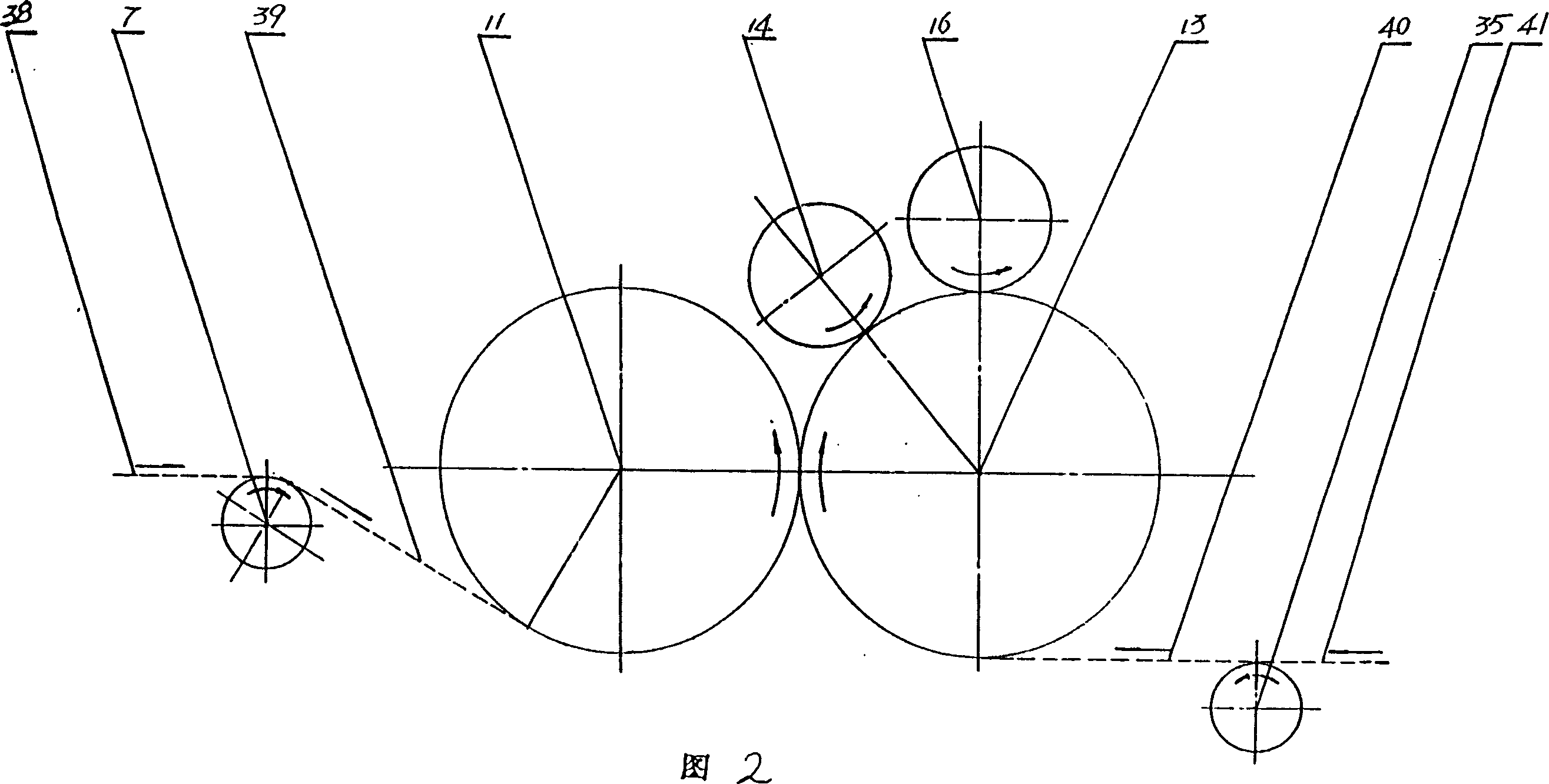

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

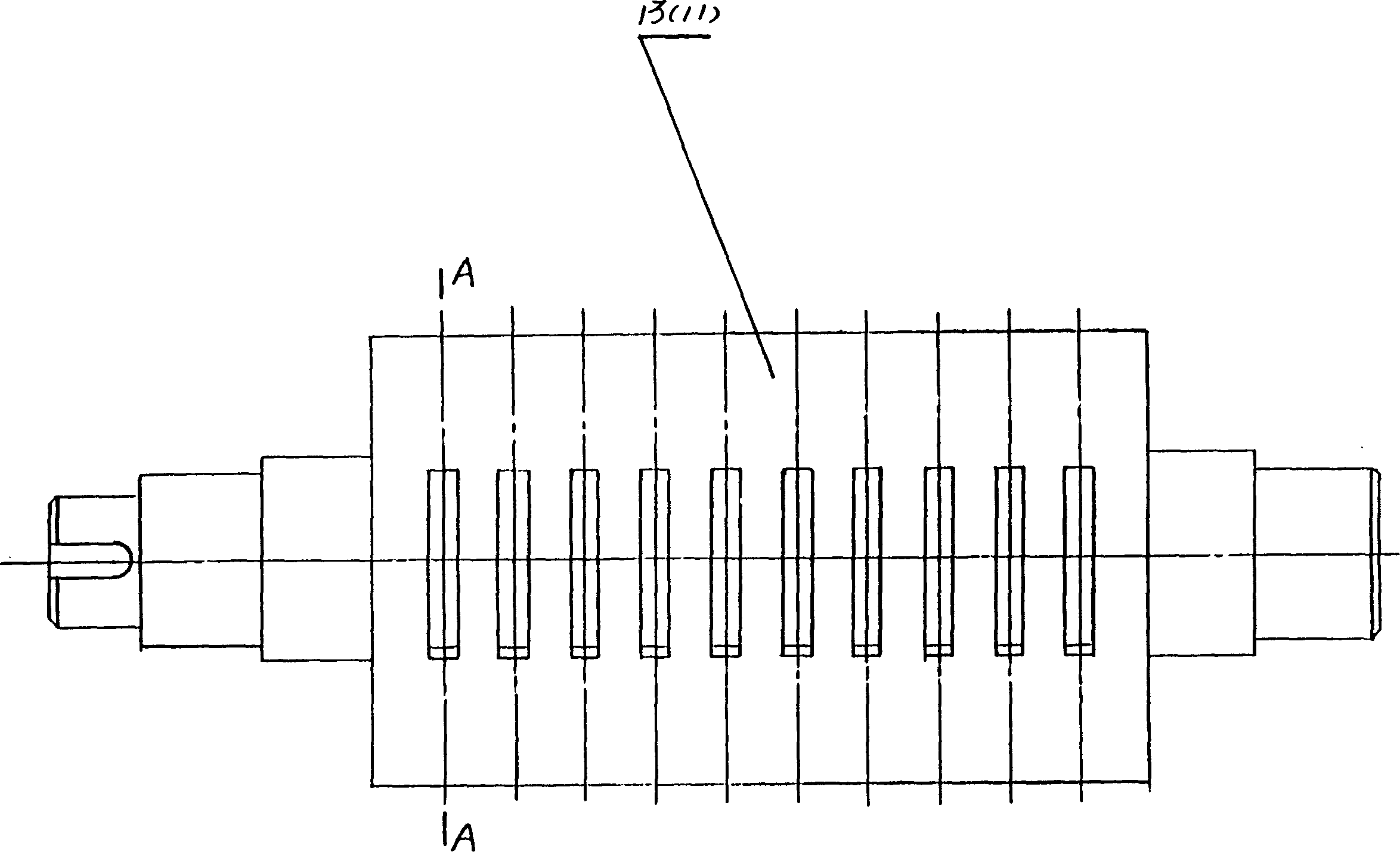

[0022] The present invention adopts wallboard 1 to be installed on the base 2 by hexagon socket head cap screws. The paper-feeding wallboards 6 and 37 in the paper-feeding device are connected to the wallboard 1 by hexagon socket head screws, and the paper-feeding rollers 7 and 35 in the paper-feeding device are installed in the holes of the wallboard 1 through the bearings on their shafts. 8 and 34 are installed on the paper feed rollers 7 and 35 by flat keys, and the bridge gear 10 and the bridge sprocket 9, the bridge gear 32 and the bridge sprocket 33 are installed on the wallboard 1 through the short shaft and the bearing respectively. The nip roller 4 in the gluing device is installed in the hole of the wallboard 1 through the slider, the rubber roller 5 is installed in the hole of the wallboard 1 through the bearing on its shaft, and the glue gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com