A porcelain bowl processing and forming machine

A molding machine and porcelain bowl technology, which is applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of laborious work, easy hand injury by the circular frame, etc., and achieve the effect of avoiding slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

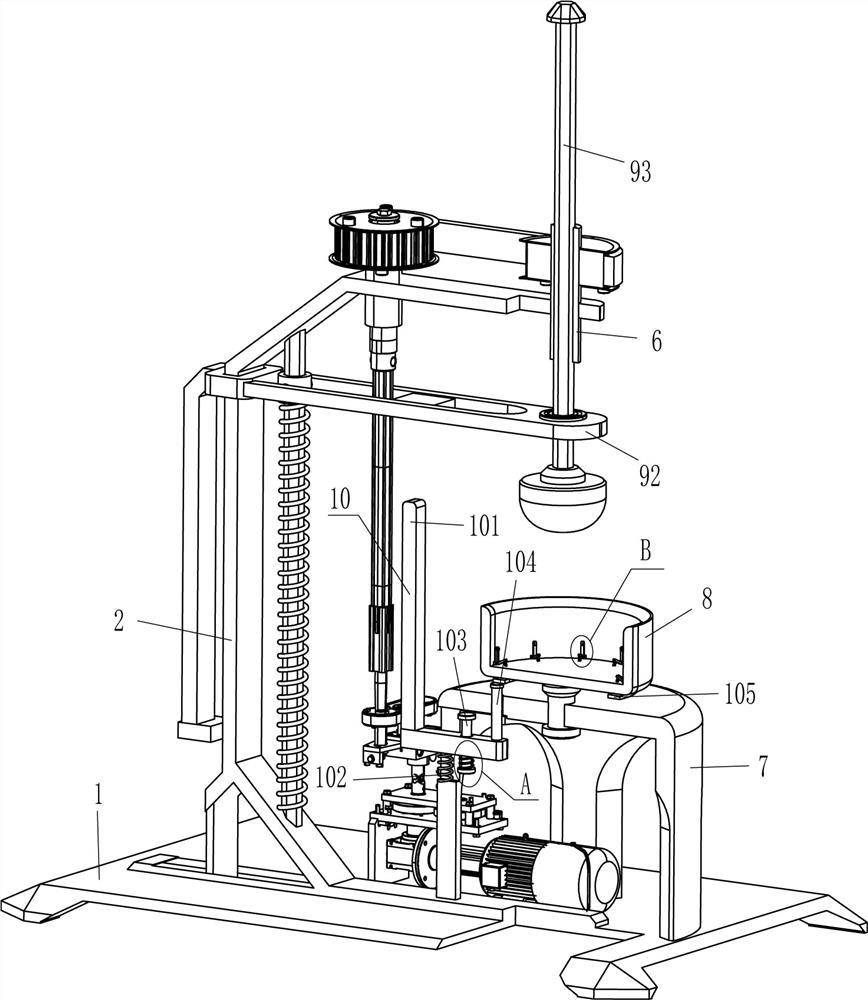

[0022] A porcelain bowl processing and forming machine, such as figure 1 As shown, it includes a base 1, a frame 2, a rotating shaft 3, a geared motor 4, a transmission assembly 5, an inner hexagonal hollow sleeve 6, a support platform 7, a circular frame 8 and a processing device 9, and the front part on the right side of the top of the base 1 is fixed. Connected with a support platform 7, a circular frame 8 is connected to the center of the support platform 7 in a rotating manner, the front side of the top of the base 1 is fixedly connected with a frame 2, and the top left side of the frame 2 is rotatably connected with a rotating shaft 3. The right side of the top of the frame 2 is connected with a hexagonal hollow sleeve 6 in a rotating manner. A transmission assembly 5 is connected between the upper circumference of the outer surface of the inner hexagonal hollow sleeve 6 and the top of the rotating shaft 3. The middle of the top right side of the base 1 is connected by bo...

Embodiment 2

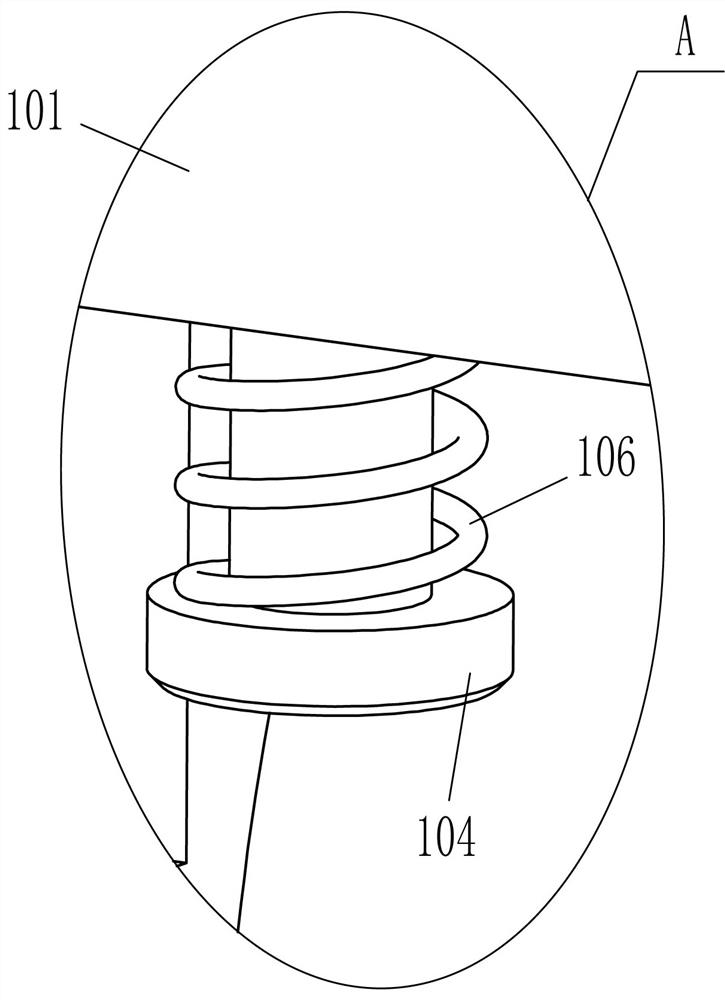

[0027] On the basis of Example 1, such as Figure 1-Figure 3As shown, a clamping mechanism 10 is also included, and the clamping mechanism 10 includes an L-shaped movable plate 101, a second spring 102, a damping rod 103, a contact rod 104, a contact ring 105 and a third spring 106, and the left side of the support platform 7 The upper sliding type is pierced with an L-shaped movable plate 101 that cooperates with the horizontal plate 92. A second spring 102 is connected between the left side of the outer bottom of the L-shaped movable plate 101 and the inside of the support platform 7, and the right part of the L-shaped movable plate 101 slides. There is a damping rod 103 in the threaded connection, the top of the damping rod 103 is in contact with the inner top of the support platform 7, and a third spring 106 is wound between the inner bottom of the damping rod 103 and the outer bottom of the L-shaped movable plate 101, and the outer part of the circular frame 8 A contact r...

Embodiment 3

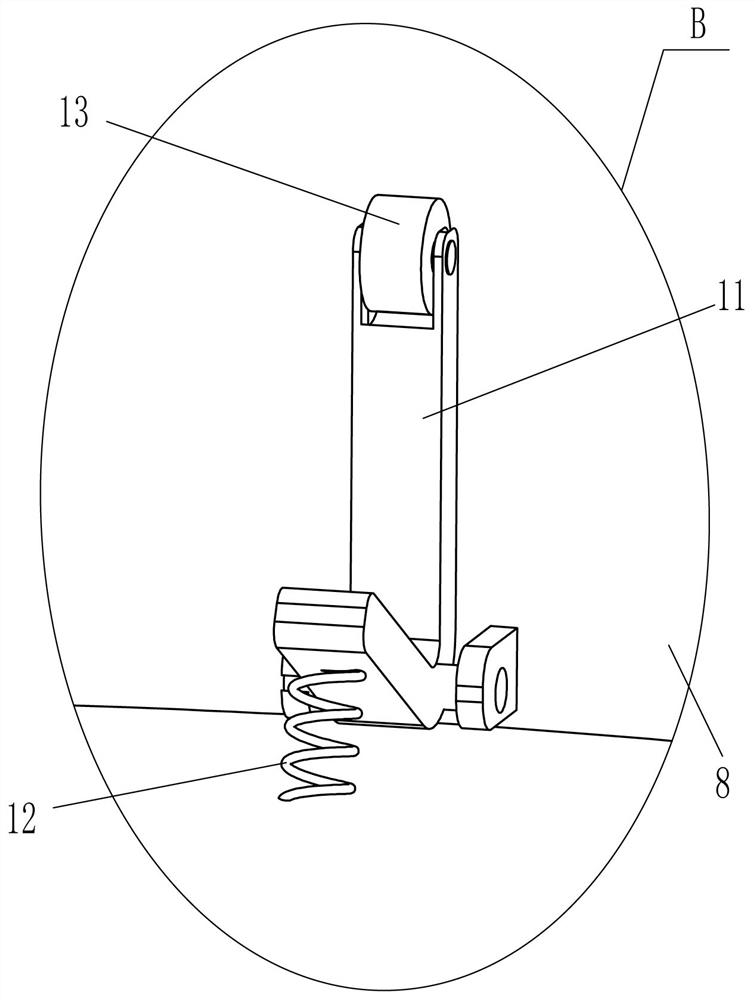

[0030] On the basis of embodiment 1 and embodiment 2, such as figure 2 and Figure 4 As shown, it also includes an L-shaped bar 11 and a fourth spring 12. The L-shaped bar 11 is hinged evenly spaced circumferentially on the lower part of the inner surface of the supporting platform 7, and the inner bottom of the L-shaped bar 11 is connected with the inner bottom of the supporting platform 7. The fourth spring 12 .

[0031] It also includes a contact wheel 13, and the top end of the L-shaped bar 11 is rotatably connected with the contact wheel 13.

[0032] When the container that pottery clay is housed is put into circular frame 8, when container contacts with L-shaped bar 11, container drives L-shaped bar 11 inner end to swing downwards, and the 4th spring 12 compresses, and L-shaped bar 11 inner end The lower swing makes the top swing inward, and the top of the L-shaped bar 11 swings inward to contact the container to fix it. When the clay is processed into a porcelain bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com