A method for reducing fuel pressure fluctuations in high-pressure fuel pipes of electronically injected diesel engines

A high-pressure oil pipe, fuel pressure technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., to save manpower, reduce fluctuations, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

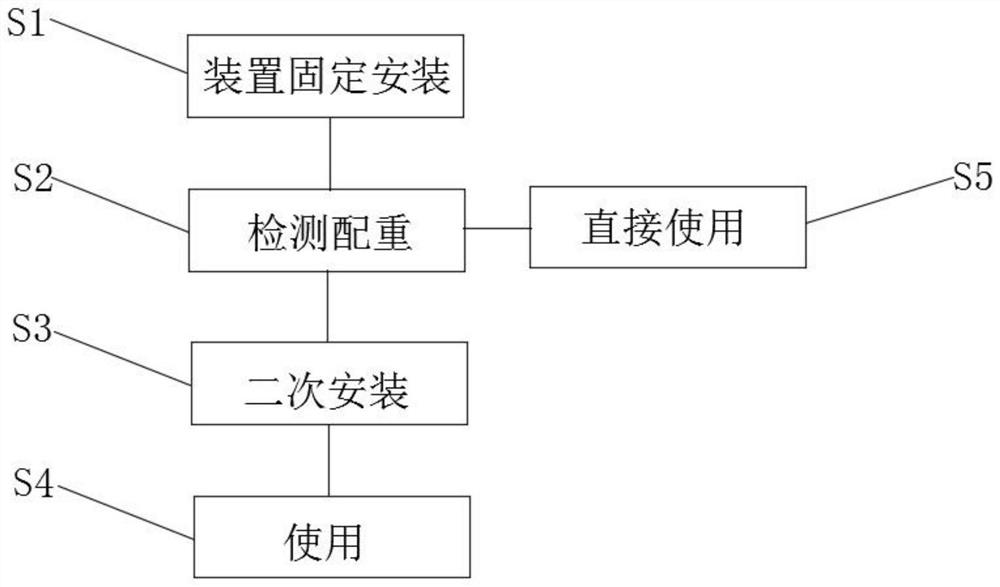

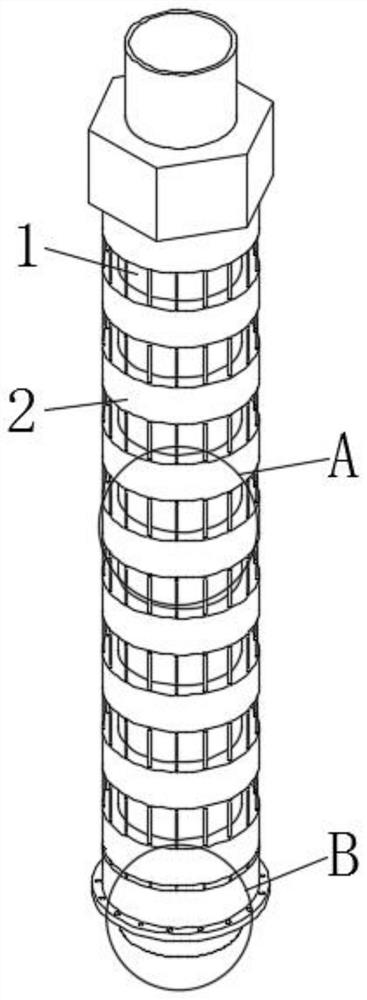

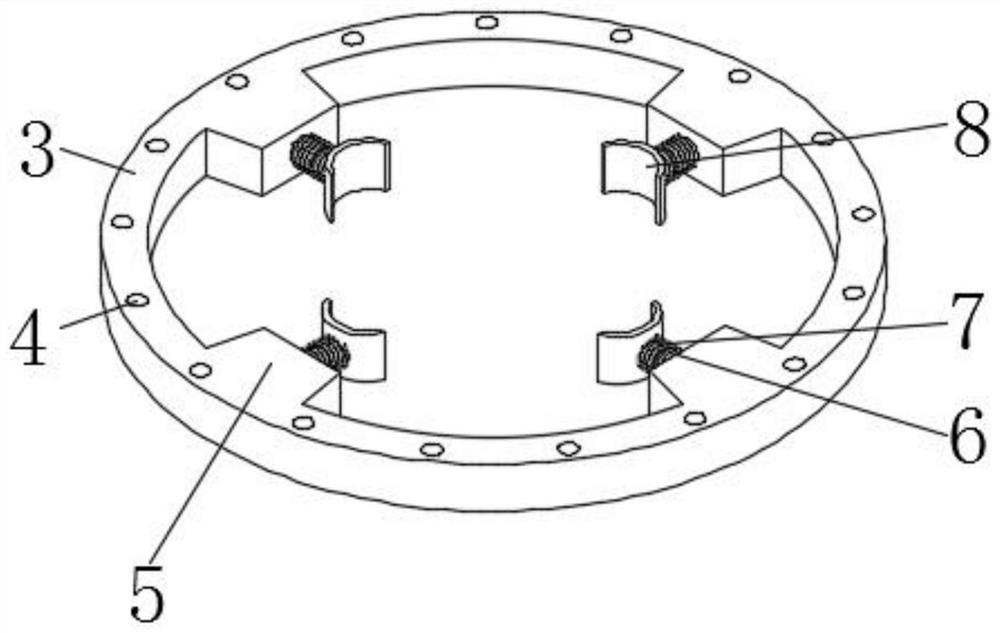

[0030] see Figure 1-5 , a method for reducing fuel pressure fluctuations in the high-pressure fuel pipe of an EFI diesel engine, including the following process: S1, fixed installation of the device: the shock-absorbing mechanism 2 is socketed outside the high-pressure fuel pipe body 1 through its own specific installation method, and the shock-absorbing mechanism 2. It consists of a fixed frame 3, a through hole 4, a fixed block 5, a cylinder 6, a spring 7, a block 8, a fixed seat 9, a mounting hole 10, a fixed rod 11, and a spacer sleeve 12. The fixed seat 9 is located on the high-pressure oil pipe body 1, and fixedly clamped with the high-pressure oil pipe body 1, one of the fixed bases 9 is fixedly connected with several fixed rods 11, the fixed rods 11 are far away from the center position of the fixed base 9, and several fixed rods 11 are clamped The fixed frame 3, the spacer bushing 12 is installed between two adjacent fixed frames 3, the spacer bushing 12 is fixedly c...

Embodiment 2

[0036] Based on Example 1, such as Figure 1-5 , the fixed base 9 is provided with several installation holes 10, and the installation holes 10.

[0037] Working principle: When using this kind of device, one of the fixing seats 9 with the fixing rod 11 is clamped on the high-pressure oil pipe body 1 first, and then the fixing frame 3 or the spacer bushing are selected according to the model and power of the diesel engine itself. 12, if the power of the diesel engine is large, then more fixed mounts 3 can be placed, otherwise, more spacer sleeves 12 can be placed. There will be a spacer sleeve 12, which can be placed repeatedly between the fixed frame 3 and the fixed frame 3. When placing the fixed frame 3 and the spacer sleeve 12, the through hole 4 on the fixed frame 3 is sleeved on the fixed rod 11 Above, the spacer sleeve 12 can be directly socketed on the fixed rod 11. After being placed, another fixed seat 9 is socketed on the high-pressure oil pipe body 1, and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com