An automatic pressure-regulating gravel cleaning system

An automatic pressure-regulating, stone-breaking technology, applied in the field of medical devices, can solve the problems of cumbersome operation and slow response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

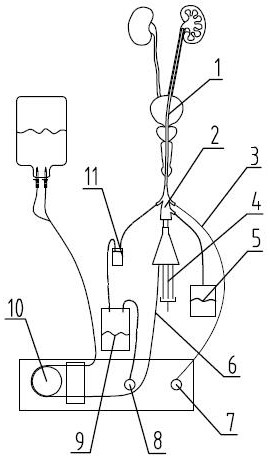

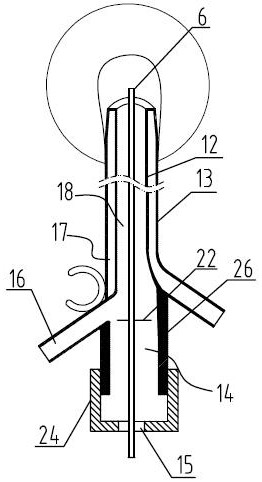

[0032] Such as figure 1 and figure 2 As shown, an automatic pressure-regulating gravel removal system includes an electronic mirror 4 and a mirror sheath, and the electronic mirror 4 includes a liquid inlet channel 6 . The mirror sheath includes a sheath body 2 and a sheath tube 1 , the sheath tube 1 is provided with a drainage channel 18 , and the sheath body 2 is provided with a transition chamber 14 communicating with the drainage channel 18 . The sheath 2 is made of transparent material, and the sheath 2 is provided with a marking line 22 . Specifically, the sheath body 2 includes a main body 26 and a cover plate 24 . The cover plate 24 is located at an end of the main body 26 away from the sheath tube 2 . The main body 26 and the cover plate 24 together form the transition chamber 14 .

[0033] Such as figure 1 and figure 2 As shown, the sheath body 2 is provided with a liquid discharge port 16 and a pressure regulating port 15 communicating with the transition cham...

Embodiment 2

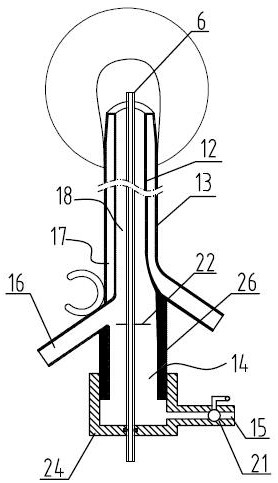

[0037] Such as image 3 As shown, compared with Embodiment 1, the difference of this embodiment is that: the sheath body 2 is also provided with an operation channel corresponding to the electronic mirror 4, and the electronic mirror 4 passes through the operation channel and communicates with the electronic mirror 4. The operating channel is slidingly sealed. The pressure regulating port 15 is set independently from the operating channel, and the pressure regulating port 15 is connected with the open liquid collection device 5. When the transition chamber 14 is filled with waste liquid and cannot be discharged in time or the liquid discharge port 16 is blocked, some The waste liquid can enter the liquid collection device 5 through the pressure regulating port 15 for temporary collection. The pressure regulating port 15 is provided with a switch 21 for controlling the opening amount of the pressure regulating port 15, and the flow rate can be changed by adjusting the opening ...

Embodiment 3

[0039] Such as Figure 4 As shown, compared with the second embodiment, the difference of this embodiment is that the pressure regulating port 15 is not provided on the cover plate 24, the sheath body 2 is provided with a confluence pipe 23, and the Both the liquid discharge port 16 and the pressure regulating port 15 communicate with the transition chamber 14 through the confluence pipe 23. With the change of the opening amount of the switch 21, the change of the liquid inlet flow rate and the liquid discharge flow rate is more sensitive, and the adjustment range is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com