Water-cooled wall pipe group and arrangement method thereof

A technology of water-cooled wall tubes and layout methods, which is applied to combustion methods, boiler water tubes, furnace cooling, etc., can solve the problems of poor cooling effect and difficulty, achieve convenient maintenance and repair, reduce manufacturing and maintenance costs, and reduce working fluids. The effect of reasonable flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

[0025] A method for arranging water-cooled wall tube groups provided by the present invention, the steps are as follows:

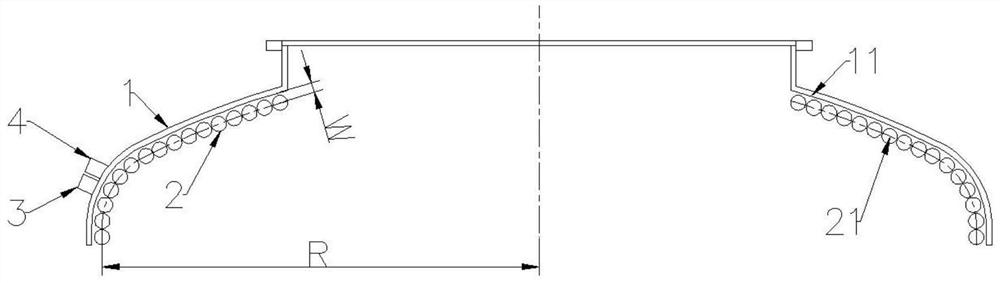

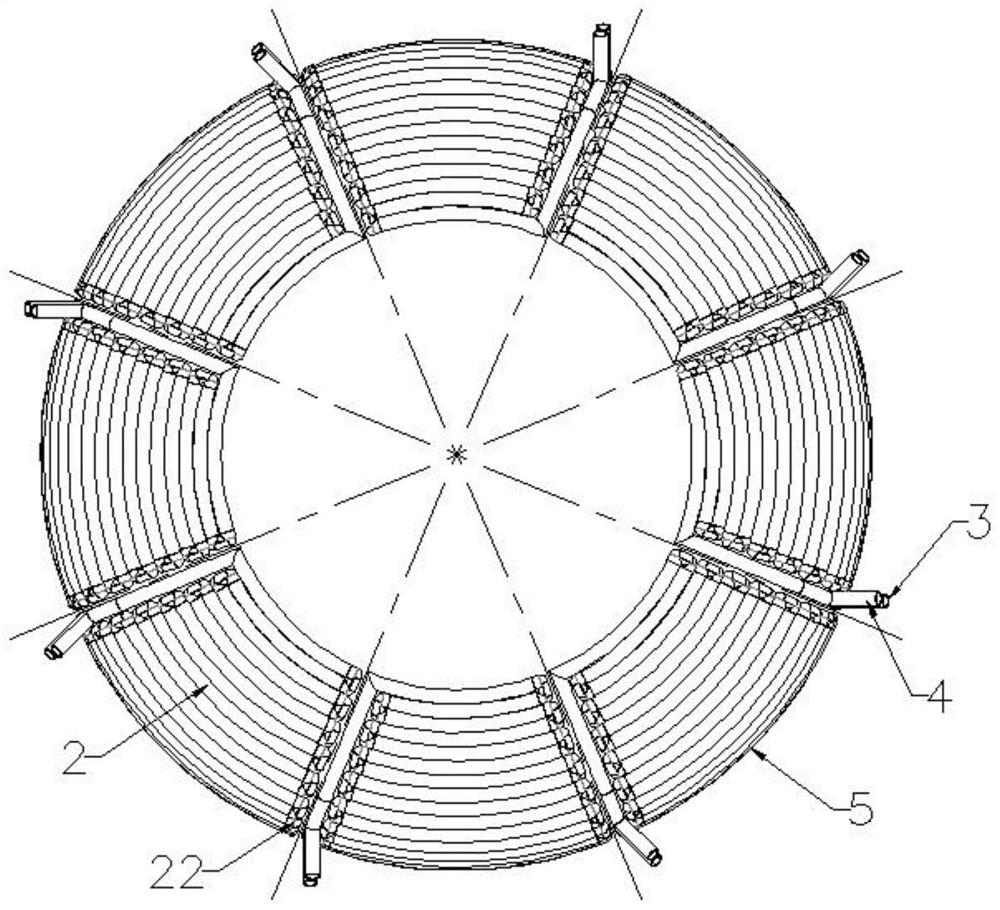

[0026] S1. Divide the boiler dish-shaped head into multiple spaces, and install a group of water-cooled wall tubes in each space to form a dish-shaped water-cooled wall tube group;

[0027] S2. Each group of water-cooled wall tubes includes a plurality of arc-shaped water pipes. The arc-shaped water pipes are placed in a single layer from bottom to top according to the curved path of the side wall of the dish-shaped head, and the upper and lower adjacent arc-shaped water pipes are connected in sequence;

[0028] S3. Connect the upper port of the water cooling wall tube to the water outlet pipe, and connect the lower po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com