An oil collector for realizing oil separation in petrochemical industry

A petrochemical and oil collector technology, applied in the field of oil collectors, can solve the problems of poor oil fluidity, pollution of the environment, waste of oil resources, etc., and achieve the effect of preventing oil dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

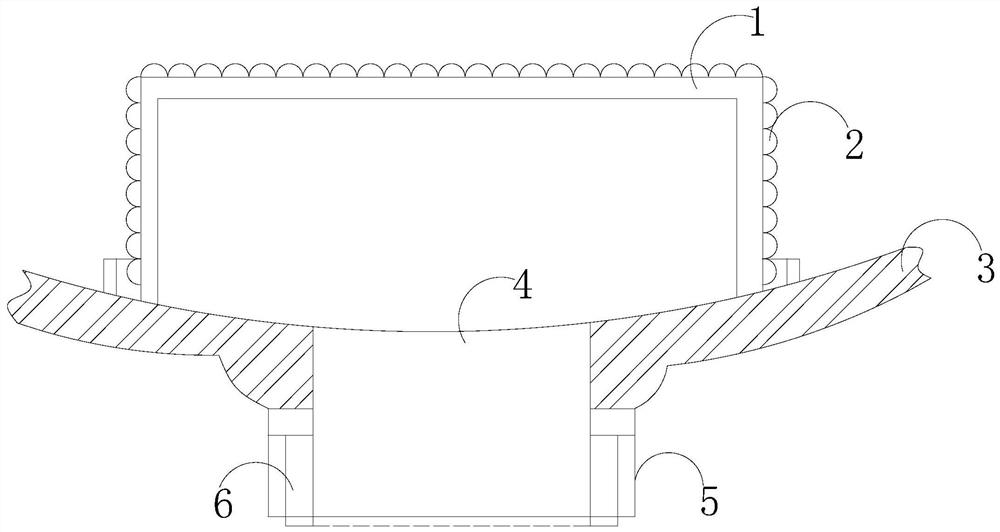

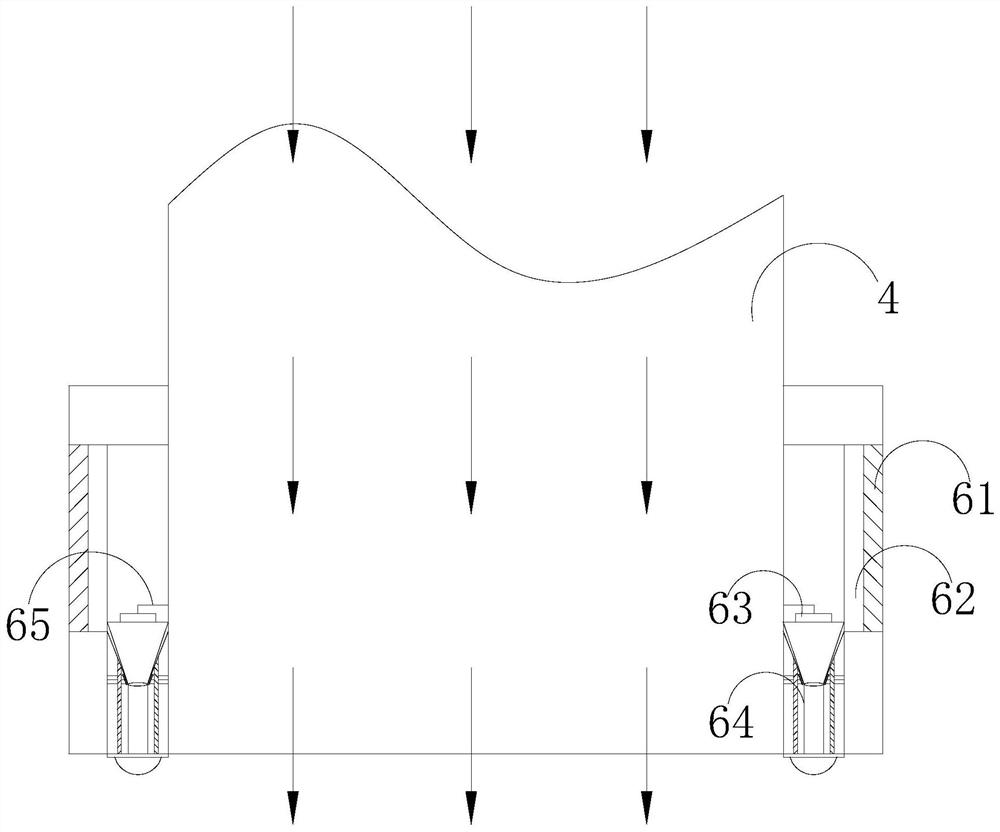

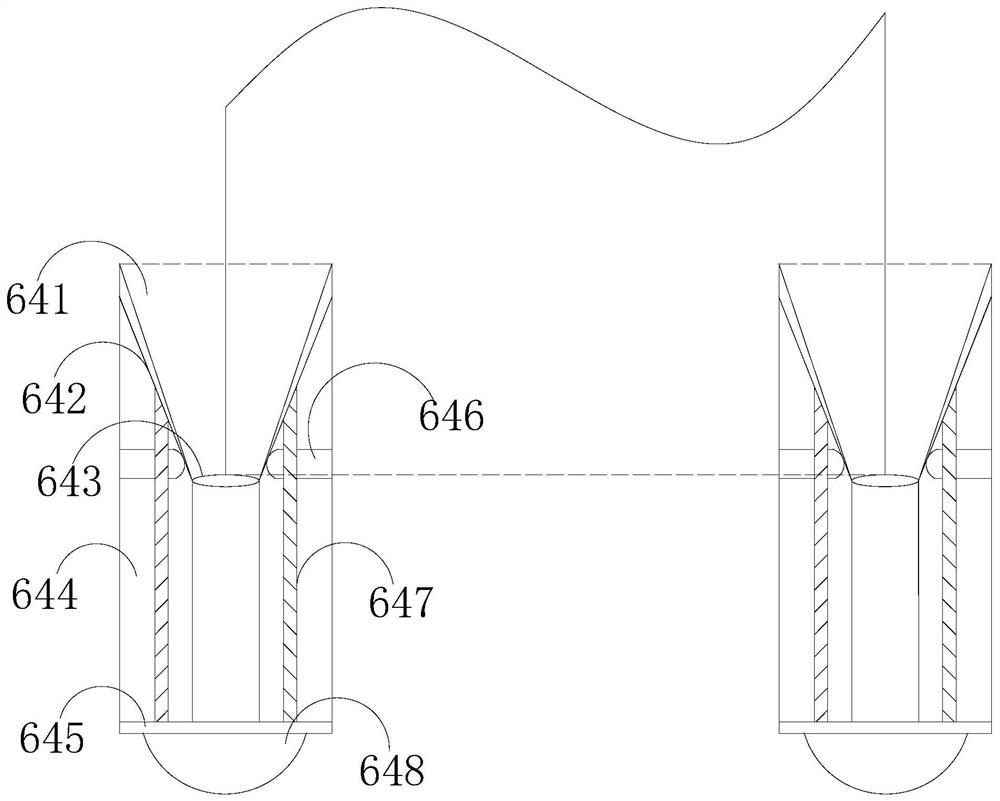

[0022] Such as Figure 1-Figure 5 As shown, the present invention provides an oil collector for realizing oil separation in petrochemical industry. Its structure includes an oil collection tank 1, a damping ball 2, a base 3, an oil collection joint 4, a pipe sleeve 5, and a liquid leakage collector 6. The outer surface of the oil collection tank 1 is provided with shock-absorbing balls 2, the oil collection tank 1 and the base 3 are welded together, the oil collection joint 4 communicates with the oil collection tank 1, and the oil collection joint 4 is nested in the sleeve 5, a leakage collector 6 is provided between the pipe sleeve 5 and the oil collection joint 4, and the leakage collector 6 includes a spacer 61, a lifting cylinder 62, a running wheel 63, a recovery device 64, and a suspension cable 65. The lifting cylinder 62 is in contact with the spacer 61 , and the lifting cylinder 62 is mechanically connected with the recovery device 64 , and the recovery device 64 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com