Oil collector for realizing petroleum separation in petrochemical engineering

A petrochemical and oil collector technology, applied in the field of oil collectors, can solve the problems of polluting the environment, wasting oil resources, poor oil fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

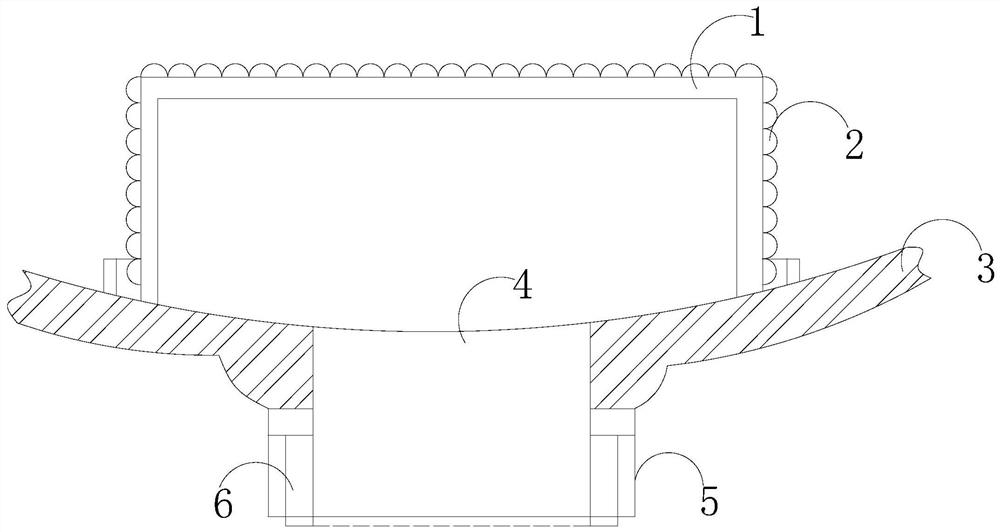

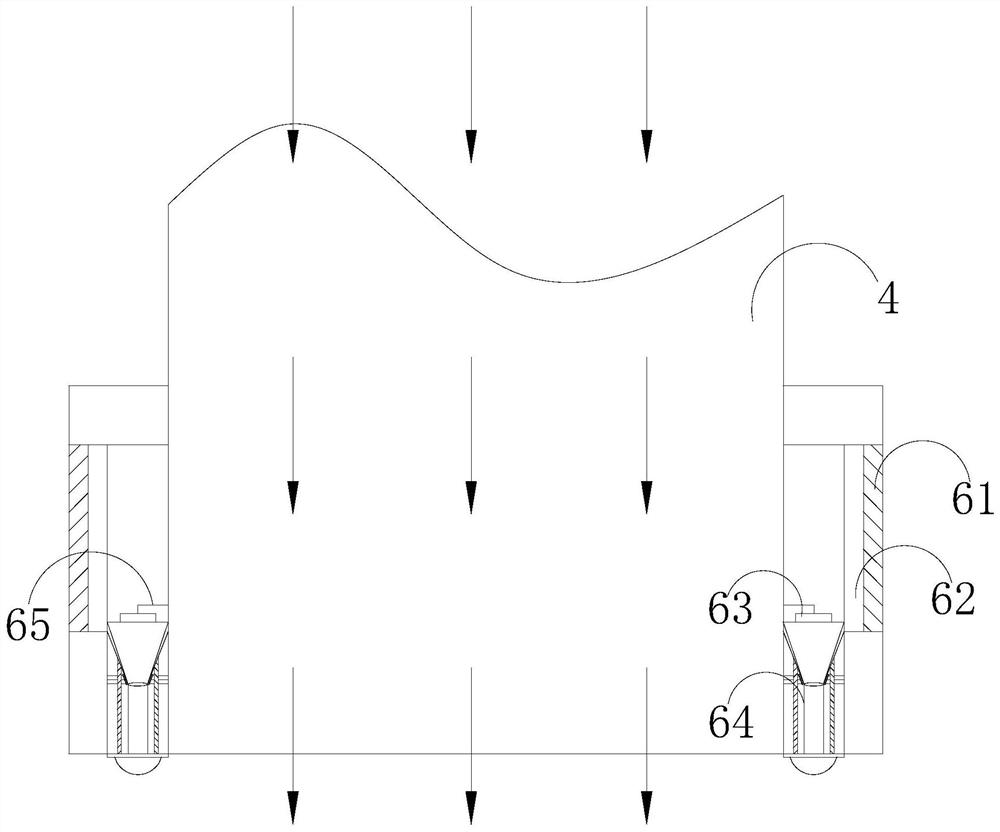

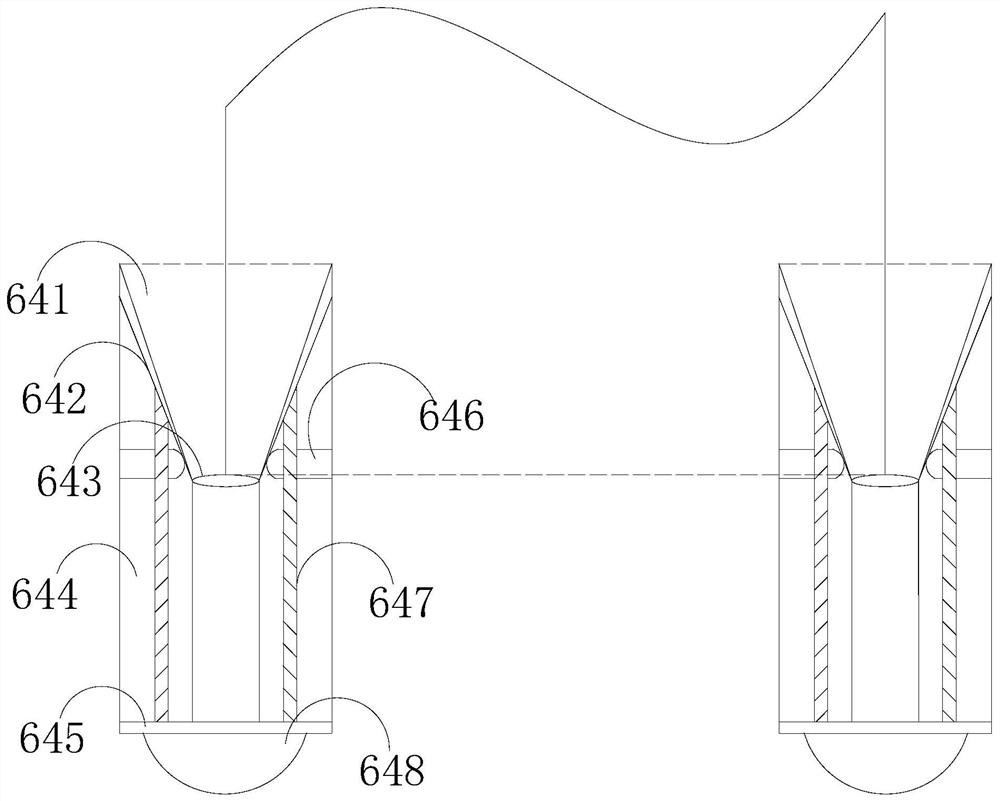

[0022] like Figure 1-Figure 5 As shown, the present invention provides an oil collector for realizing oil separation in petrochemical industry. Its structure includes an oil collection tank 1, a damping ball 2, a base 3, an oil collection joint 4, a pipe sleeve 5, and a liquid leakage collector 6. The outer surface of the oil collection tank 1 is provided with shock-absorbing balls 2, the oil collection tank 1 and the base 3 are welded together, the oil collection joint 4 communicates with the oil collection tank 1, and the oil collection joint 4 is nested in the sleeve 5, a leakage collector 6 is provided between the pipe sleeve 5 and the oil collection joint 4, and the leakage collector 6 includes a spacer 61, a lifting cylinder 62, a running wheel 63, a recovery device 64, and a suspension cable 65. The lifting cylinder 62 is in contact with the spacer 61 , and the lifting cylinder 62 is mechanically connected with the recovery device 64 , and the recovery device 64 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com