An automatic control overturning device and overturning method

A technology of automatic control and turning device, which is applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of complex structure of the plate turning machine and the inability to realize automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

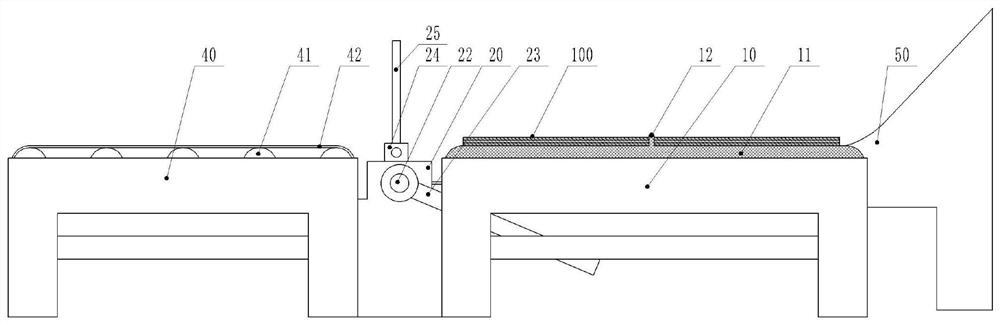

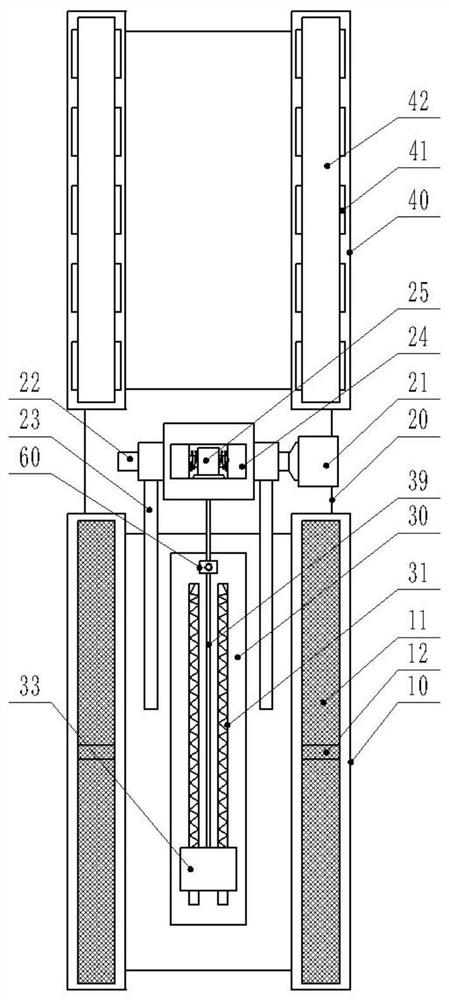

[0058] An automatic control turning device, wherein, such as figure 1 , 2 As shown, it includes: a material table 10 and a turning mechanism 20 . The material table 10 is composed of separate platforms on both sides, and the middle of the material table 10 is a movable space. The inversion mechanism 20 is disposed at the side end of the material table 10 , and the inversion mechanism 20 has: a driving motor 21 , a main shaft 22 , an inversion rod 23 , a material receiving seat 24 , a material receiving plate 25 , and a return spring 241 .

[0059] The main shaft 22 is connected to the drive motor 21 , and there are at least two inversion rods 23 , the inversion rods 23 are connected to the main shaft 22 , and the inversion rods 23 are distributed under both sides of the movable space. The material receiving seat 24 is located at the upper end of the main shaft 22 .

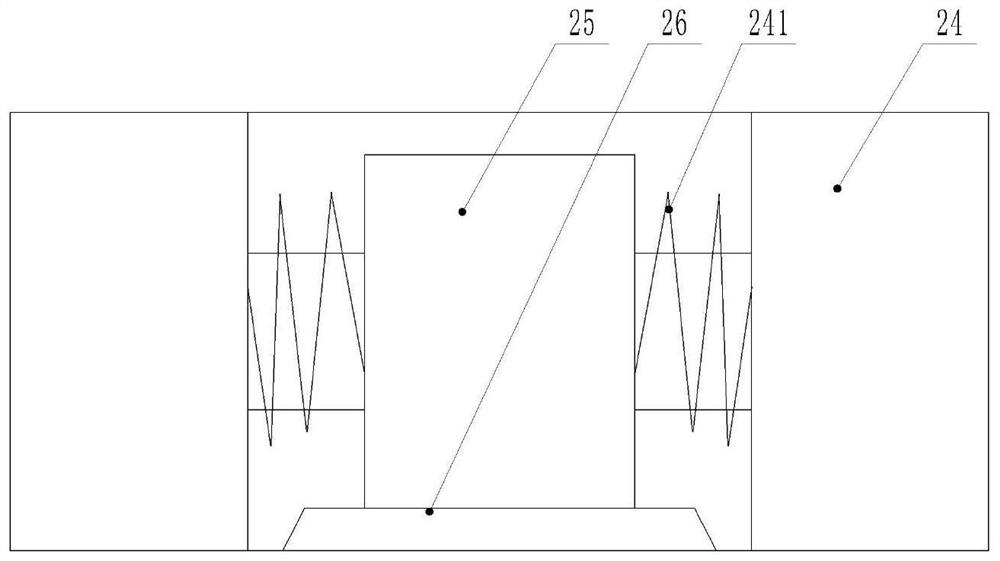

[0060] like image 3 As shown, the material receiving plate 25 is disposed upward, the material receiving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com