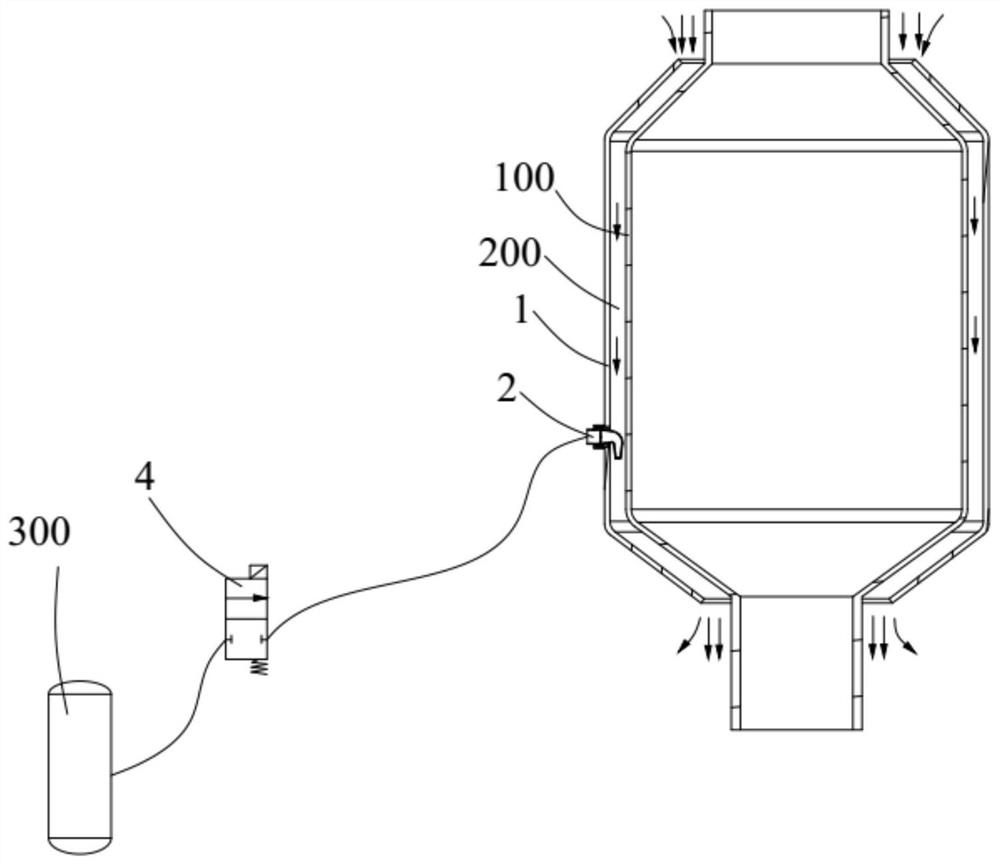

Heat-insulation cover

A technology of heat shield and heat source, applied in layered products, mechanical equipment, metal layered products, etc., can solve the problems of neglecting heat dissipation requirements, heat accumulation of heat source parts, and ineffective heat insulation of heat shields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

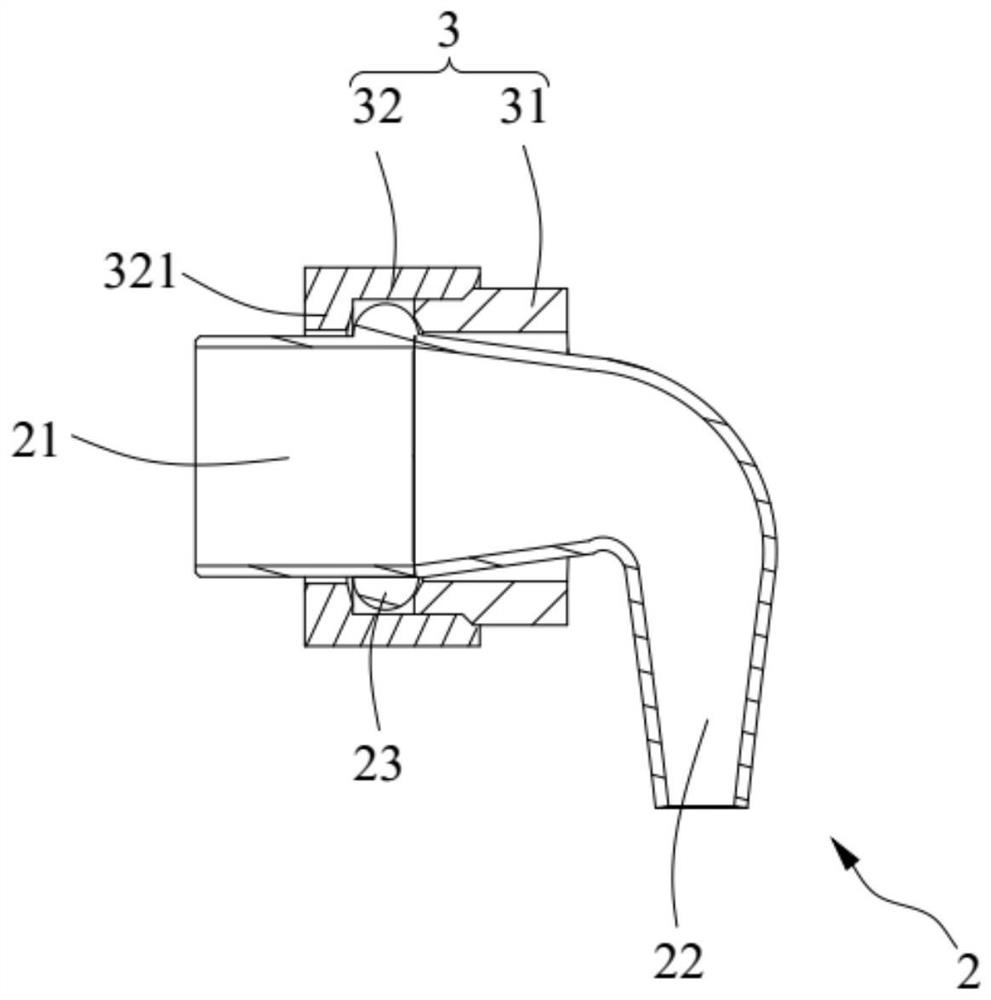

[0028] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved more clear, the technical solutions of the present invention will be further described below with reference to the drawings and specific implementations.

[0029] In the description of the present invention, unless otherwise clearly specified and limited, the terms "connected", "connected", and "fixed" should be interpreted broadly, for example, they may be fixedly connected, detachably connected, or integrated ; It can be a mechanical connection or an electrical connection; it can be directly connected or indirectly connected through an intermediate medium, and it can be the internal communication between two components or the interaction relationship between two components. For those of ordinary skill in the art, the specific meaning of the above-mentioned terms in the present invention can be understood in specific situations.

[0030...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap