Low-infrared-thermal-radiance polymer nano-net as well as preparation method and application thereof

A technology of heat radiation rate and infrared radiation, which is applied in the direction of single-component synthetic polymer rayon, sputtering coating, textiles and papermaking, etc., can solve the problems of reducing hand dexterity, achieve high heat radiation shielding rate, consume The effect of less, high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

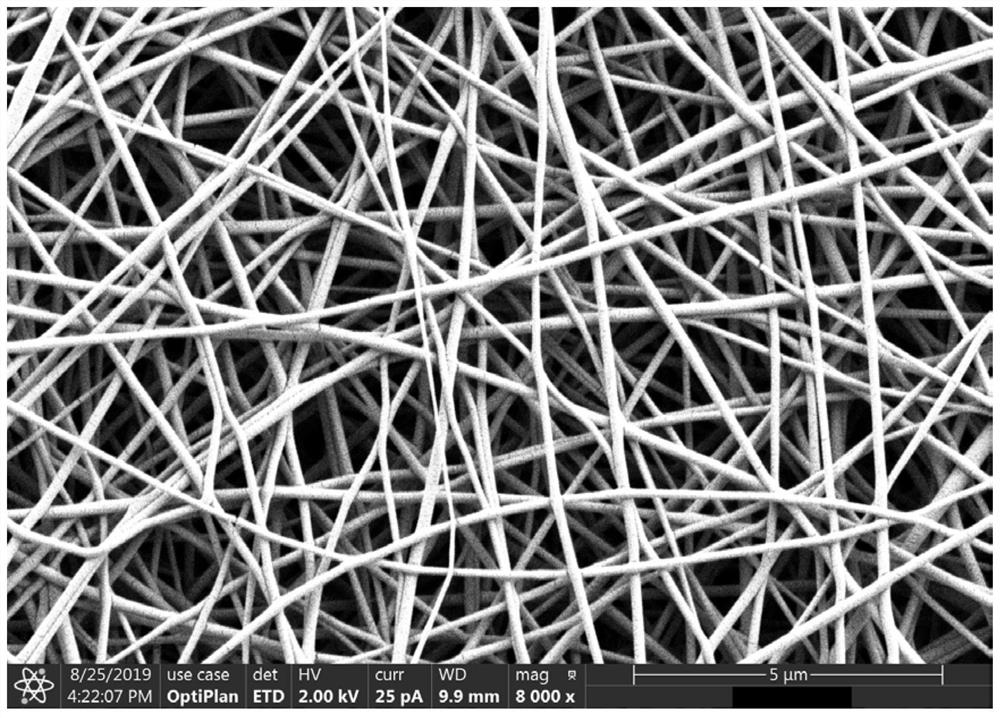

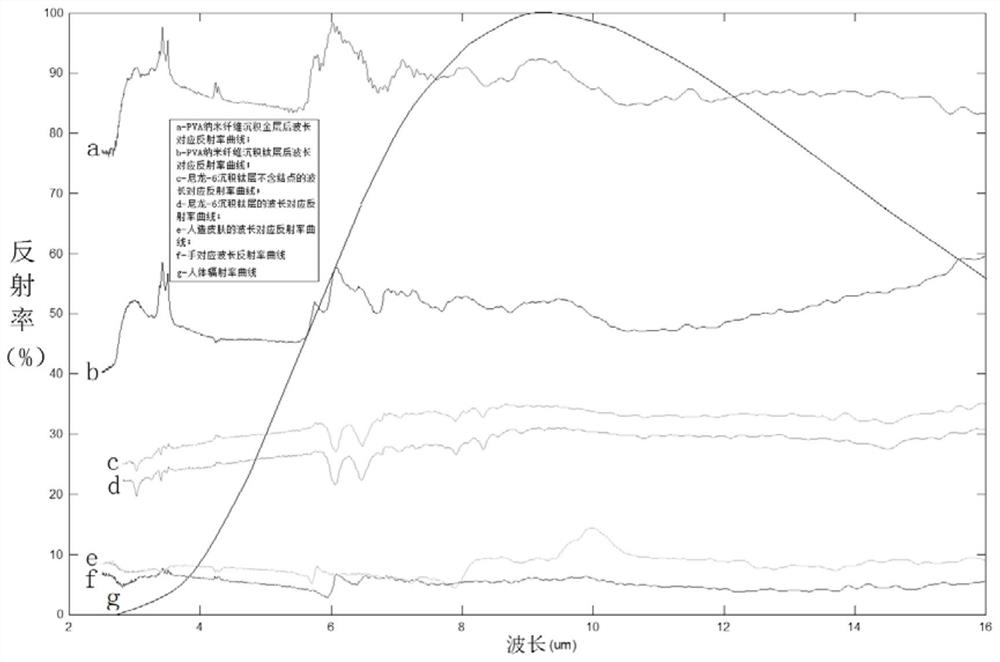

[0043] A polymer nanonet with low infrared heat emissivity includes a base layer and a metal layer deposited on the base layer, the base layer is a PVA nanofiber layer, and the metal layer is a gold layer and a titanium layer.

[0044] The preparation method of the PVA nanofiber layer is as follows: 10wt% PVA of the aqueous solution is packed into the syringe, and the needle point of the syringe is connected to a DC power supply, and an electric potential is applied. The electric potential is 15kV, and the pump speed is 0.02ml / h. 15cm to obtain PVA nanofibers, and then use electron beam evaporation to deposit a 150nm gold layer and a 150nm titanium layer on the PVA nanofibers to obtain a PVA nanofiber layer.

[0045] The present invention also proposes a polymer nanonet with low infrared thermal emissivity, comprising the following steps:

[0046] S1, prepare PVA nanofiber layer;

[0047]S2. Coating a 0.03mm acrylic ink layer on the P-type boron-doped silicon wafer to produce...

Embodiment 2

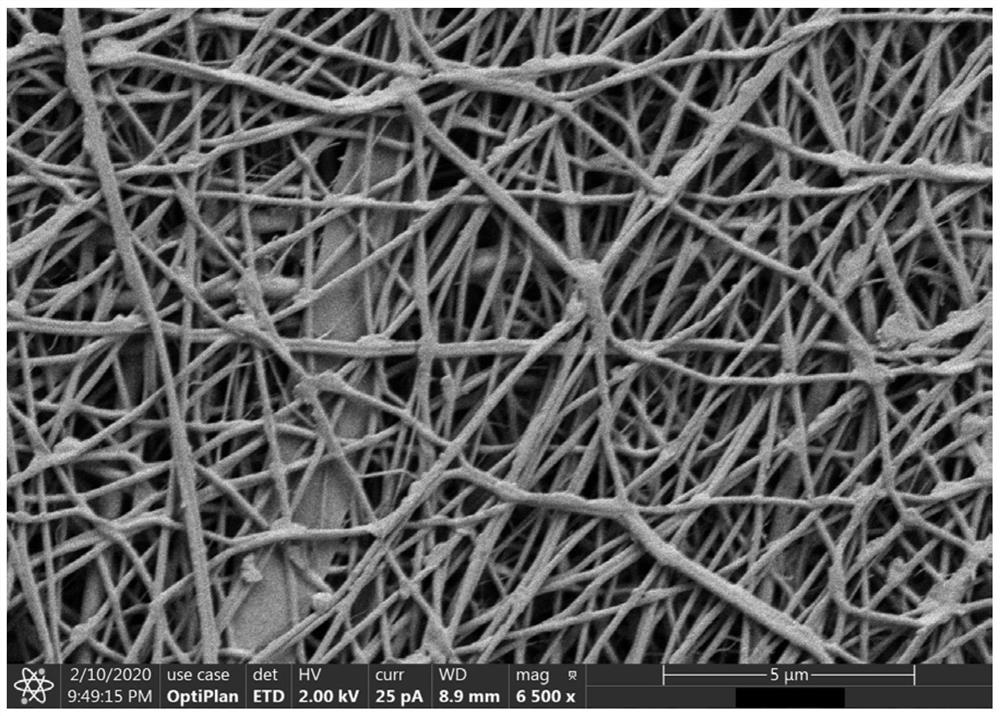

[0051] A polymer nanonet with low infrared heat emissivity includes a base layer and a metal layer deposited on the base layer, the base layer is a nylon-6 nanofiber layer, and the metal layer is a titanium layer.

[0052] The preparation method of the nylon-6 nanofiber layer is as follows: 20wt% nylon-6 of the formic acid solution is packed into a syringe, and the needle point of the syringe is connected to a DC power supply, and an electric potential is applied, the electric potential is 20kV, and the pump speed is 0.2ml / h , the needle collector distance is 17cm to obtain nylon-6 nanofibers, and then use electron beam evaporation coating to deposit a 150nm titanium layer on the nylon-6 nanofibers to obtain a nylon-6 nanofiber layer.

[0053] The preparation method of the nylon-6 nanofiber layer further includes: hot-rolling the nylon-6 nanofibers at a heating temperature of 100° C. for 10 cycles.

[0054] The present invention also proposes a polymer nanonet with low infrare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap