Camera optics

An optical lens, optical total length technology, applied in the field of optical lens, can solve the problems of wide-angle, insufficient ultra-thin and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

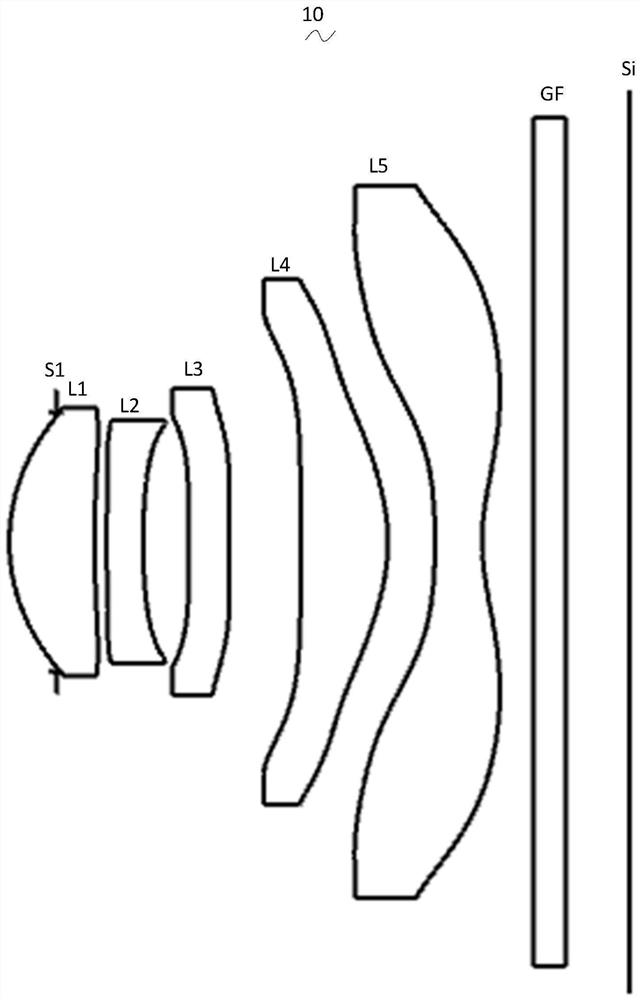

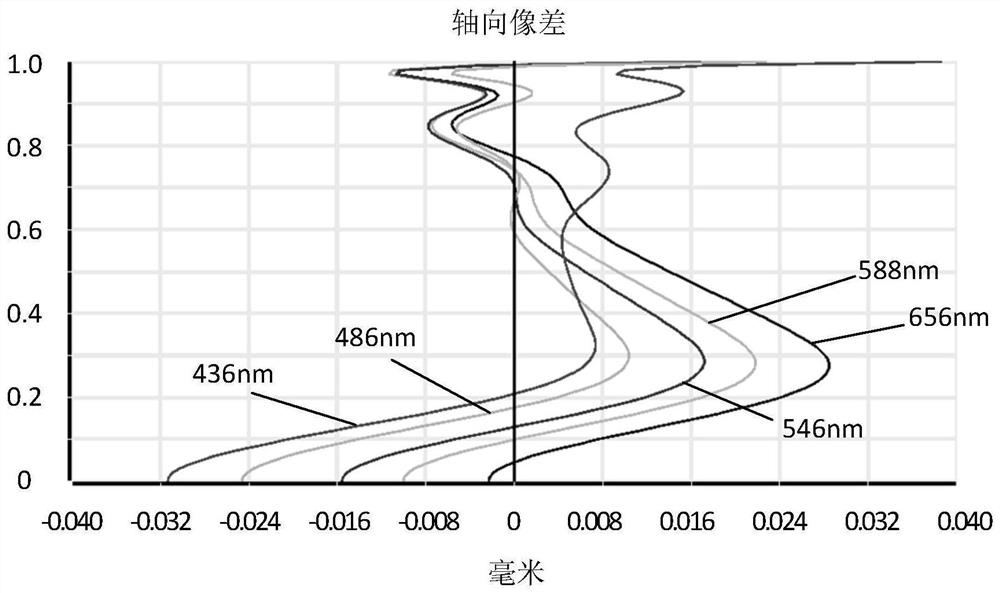

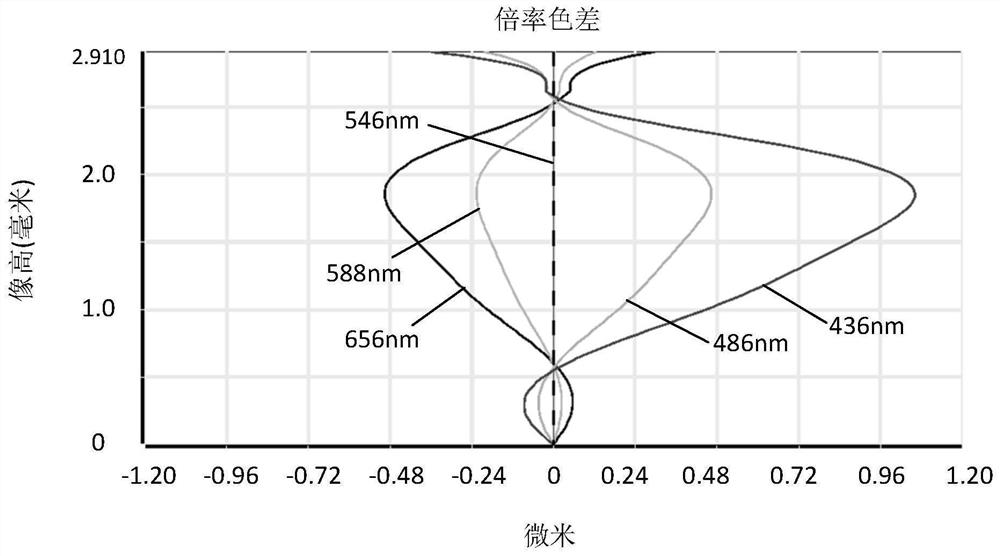

[0054] Please also refer to Figure 1 to Figure 4 , the present invention provides the imaging optical lens 10 of the first embodiment. exist figure 1 Among them, the left side is the object side, the right side is the image side, the imaging optical lens 10 mainly includes five lenses, from the object side to the image side are the aperture S1, the first lens L1, the second lens L2, the third lens L3, The fourth lens L4 and the fifth lens L5. A glass flat plate GF is provided between the fifth lens L5 and the image plane Si, and the glass flat plate GF may be a glass cover plate or an optical filter.

[0055] In this embodiment, the first lens L1 has a positive refractive power; the second lens L2 has a negative refractive power; the third lens L3 has a negative refractive power; the fourth lens L4 has a positive refractive power; and the fifth lens L5 has a negative refractive power .

[0056]In this embodiment, the first lens L1 is made of plastic material, the second l...

no. 2 approach

[0164] Figure 5 It is a schematic structural diagram of the imaging optical lens 20 in the second embodiment. The second embodiment is basically the same as the first embodiment, and the meanings of the symbols in the following list are also the same as those of the first embodiment, so the same parts will not be repeated here. Only the differences are listed below.

[0165] In this embodiment, the object side surface of the second lens L2 is concave at the paraxial position.

[0166] Table 5 and Table 6 show design data of the imaging optical lens 20 according to the second embodiment of the present invention.

[0167] 【table 5】

[0168]

[0169]

[0170] Table 6 shows aspherical surface data of each lens in the imaging optical lens 20 according to the second embodiment of the present invention.

[0171] 【Table 6】

[0172]

[0173]

[0174] Table 7 and Table 8 show the design data of the inflection point and the stagnation point of each lens in the imaging op...

no. 3 approach

[0182] Figure 9 It is a schematic structural diagram of the imaging optical lens 30 in the third embodiment. The third embodiment is basically the same as the first embodiment, and the meanings of the symbols in the following list are also the same as those of the first embodiment, so the same parts will not be repeated here. Only the differences are listed below.

[0183] In this embodiment, the object side surface of the second lens L2 is concave at the paraxial position.

[0184] Table 9 and Table 10 show design data of the imaging optical lens 30 according to the third embodiment of the present invention.

[0185] 【Table 9】

[0186]

[0187] Table 10 shows aspherical surface data of each lens in the imaging optical lens 30 according to the third embodiment of the present invention.

[0188] 【Table 10】

[0189]

[0190] Table 11 and Table 12 show the design data of the inflection point and the stagnation point of each lens in the imaging optical lens 30 .

[019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com