Almond opening device used for manufacturing industry

An opening device and manufacturing technology, applied in application, shelling, pod removal, etc., can solve the problems of low opening efficiency, almond damage, difficulty in grasping force, etc., and achieve the effect of uniform and moderate percussion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

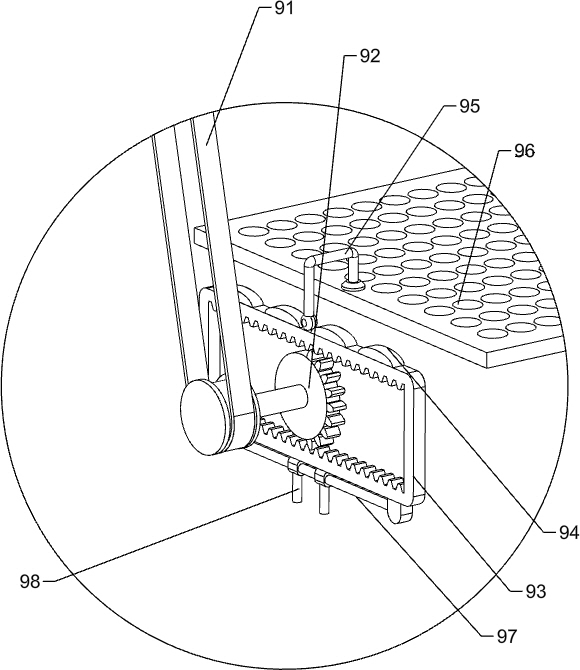

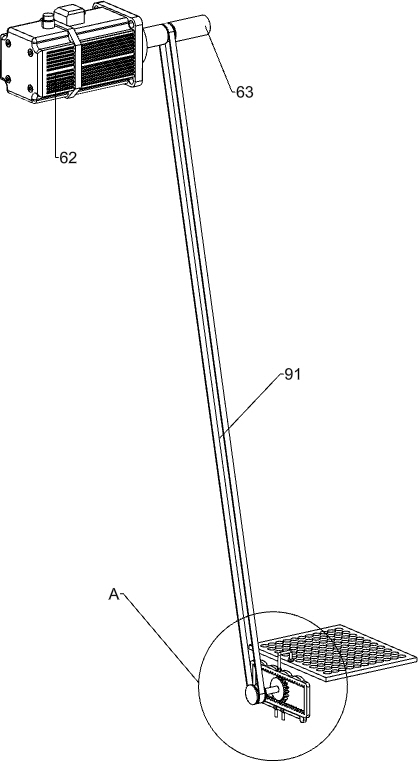

[0055] An almond opening device for manufacturing, such as Figure 1-4 As shown, it includes a base 1, a first bracket 2, a special-shaped frame 3, a collection frame 4, a discharge frame 5, a knocking mechanism 6, a moving mechanism 7 and a transmission mechanism 8, and the right side of the top of the base 1 is provided with a special-shaped frame 3, The top left side of the base 1 is provided with a first support 2 and a collection frame 4, the collection frame 4 is located on the left side of the first support 2, the top right side of the base 1 is provided with a discharge frame 5, and the upper part of the first support 2 is provided with a knocking mechanism 6 A moving mechanism 7 is connected between the top of the special-shaped frame 3 and the top of the first bracket 2, and the top of the base 1 is provided with a transmission mechanism 8.

[0056] When it is necessary to open the almonds, the staff first puts the almonds into the discharge frame 5, and then starts ...

Embodiment 2

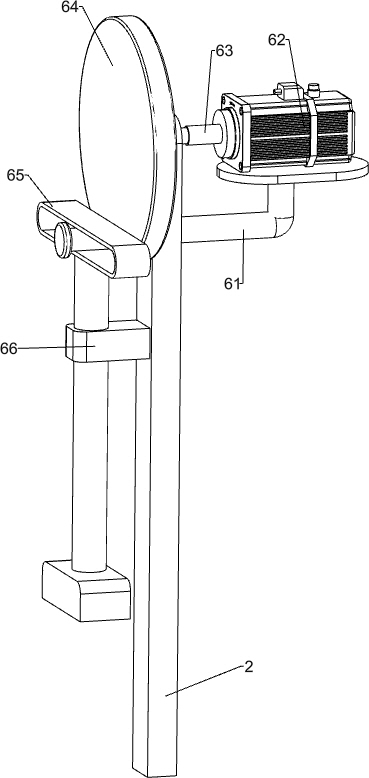

[0058] On the basis of Example 1, such as Figure 2-3 and Figure 5As shown, the striking mechanism 6 includes a mounting frame 61, a motor 62, a first rotating shaft 63, a first disc 64, a striking rod 65 and a first sliding sleeve 66, and the upper side of the rear part of the first bracket 2 is provided with a mounting frame 61, a motor 62 is provided on the top of the mounting frame 61, the output shaft of the motor 62 is connected with a first rotating shaft 63, the first rotating shaft 63 passes through the upper part of the first support 2, and the front end of the first rotating shaft 63 is connected with a first disk 64, the first The upper side of the front part of the bracket 2 is provided with a first sliding sleeve 66, and a knocking rod 65 is slidably connected to the inside of the first sliding sleeve 66, and the top of the knocking rod 65 is matched with the eccentric position of the first disk 64 through the sliding frame and the sliding shaft. .

[0059] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap