A plant beverage mixing device

A technology of mixing and stirring and plant beverages, which is applied in the direction of mixers, mixer accessories, transportation and packaging, etc., can solve problems such as difficult fixation, troublesome users, and troublesome handling of external climbing tools, so as to increase friction stability and reduce manufacturing costs. Low, the effect of enhancing the safety of pedaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

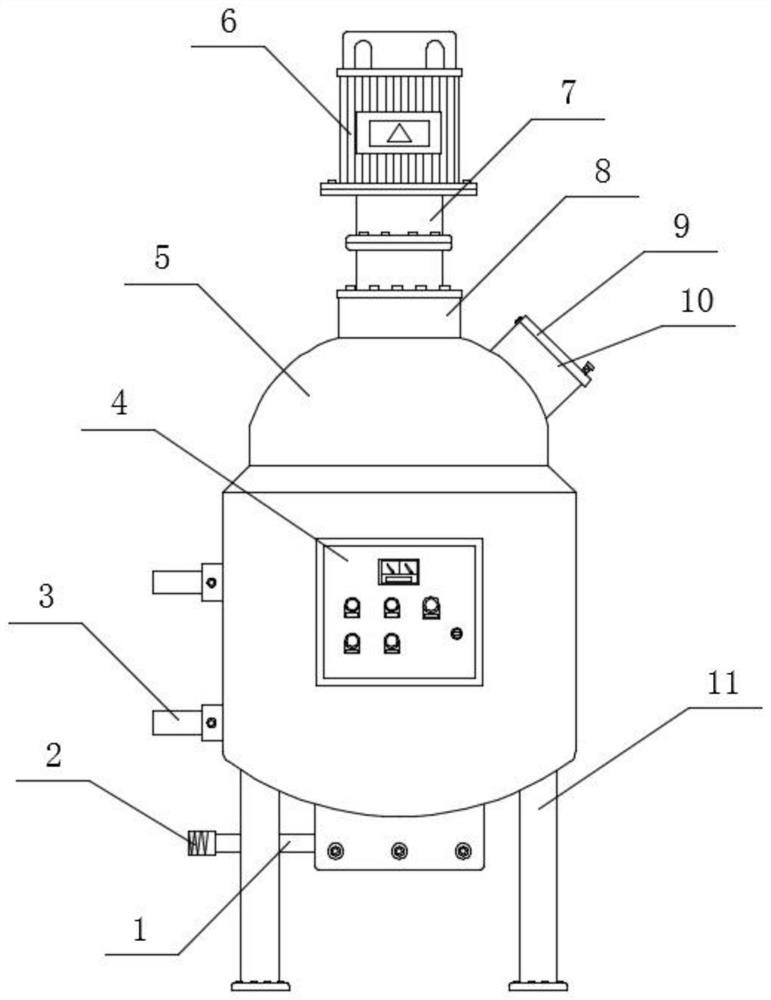

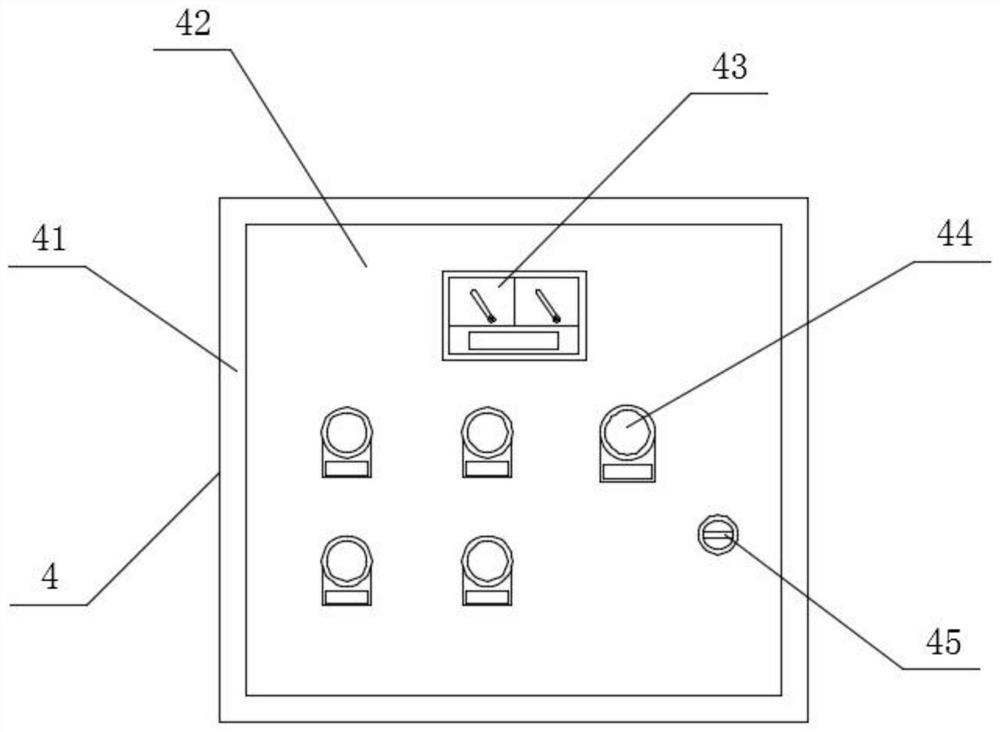

[0033] like Figure 1-4 As shown, a plant beverage mixing and stirring device includes a tank body 5 and an operation box 4. An operation box 4 is connected by welding at the front position of the outer surface of the tank body 5. The operation box 4 can be electrically connected with a motor 6. The operation box 4. It includes a box body 41, an outer box door 42, a display meter 43, a start switch 44 and a key hole 45. The front end face of the box body 41 is connected with the outer box door 42, and the upper position of the front end face of the outer box door 42 is connected with a display Table 43 shows that a start switch 44 is provided below the table 43, and a key hole 45 is provided at the lower right position of the start switch 44. The start switch 44 can control the opening and closing of the equipment as the control center of the equipment, and the lower part of the operation box 4 A fixing bracket 11 is arranged on the right side of the bottom end face of the tan...

Embodiment 2

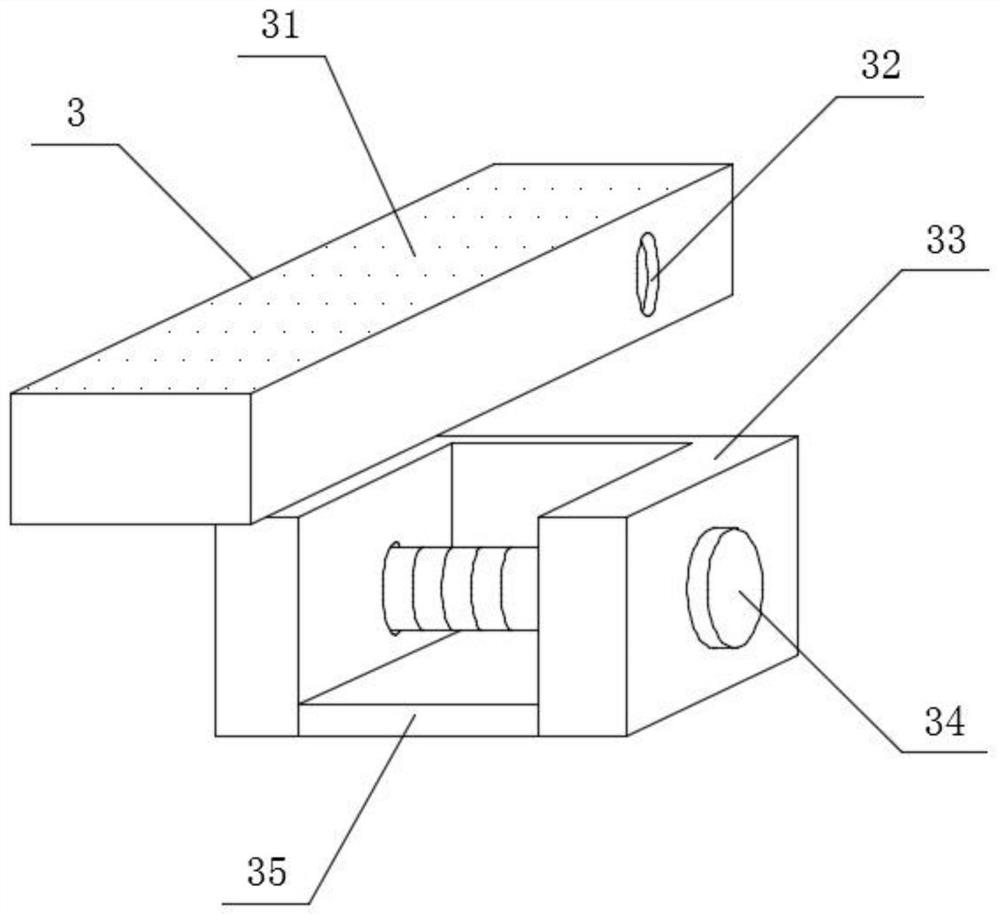

[0037] like Figure 1-9 As shown, a plant beverage mixing and stirring device includes a tank body 5 and an operation box 4. The operation box 4 is connected by welding at the front position of the outer surface of the tank body 5, and the lower part of the operation box 4 is located at the bottom end of the tank body 5. A fixed bracket 11 is arranged on the right side of the end face, and a conduction tube 1 is arranged on the left side of the fixed bracket 11. The left end face of the conduction tube 1 is connected with a liquid outlet column 2 by welding. The upper part of the liquid outlet column 2 is located on the outer surface of the tank body 5. A pedal 3 is provided at the left position, and an observation column 10 is provided at a position above and to the right of the pedal 3. The top end face of the observation column 10 is connected with an outer cover plate 9, and the upper part of the outer cover plate 9 is located in the tank body 5. A stirring port 8 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com