Diaphragm type carburetor suitable for high-temperature state

A technology of diaphragm carburetor and high temperature state, which is applied in the direction of carburetor, machine/engine, charging system, etc., and can solve problems such as engine starting is not smooth, affecting engine use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

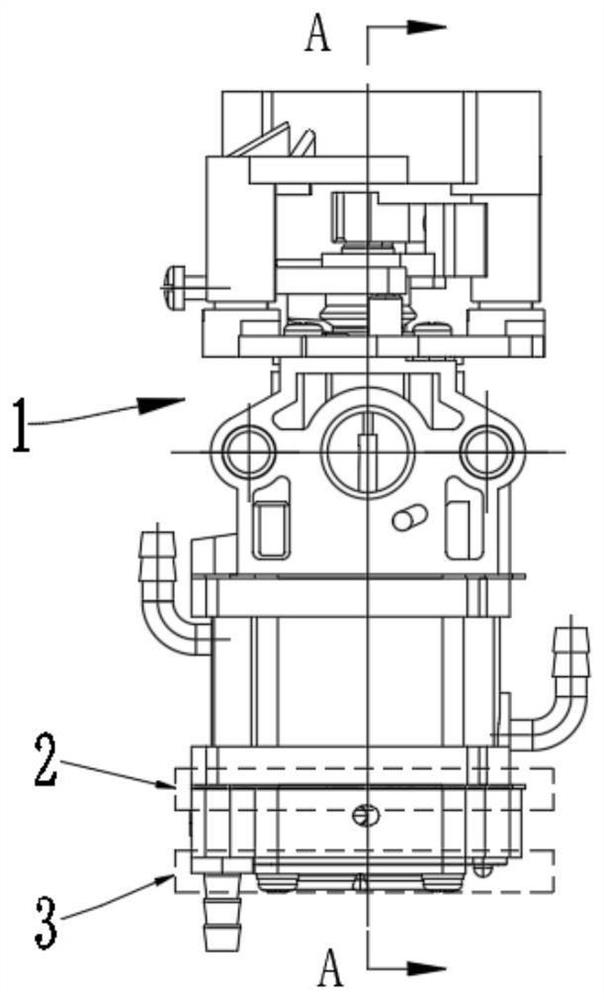

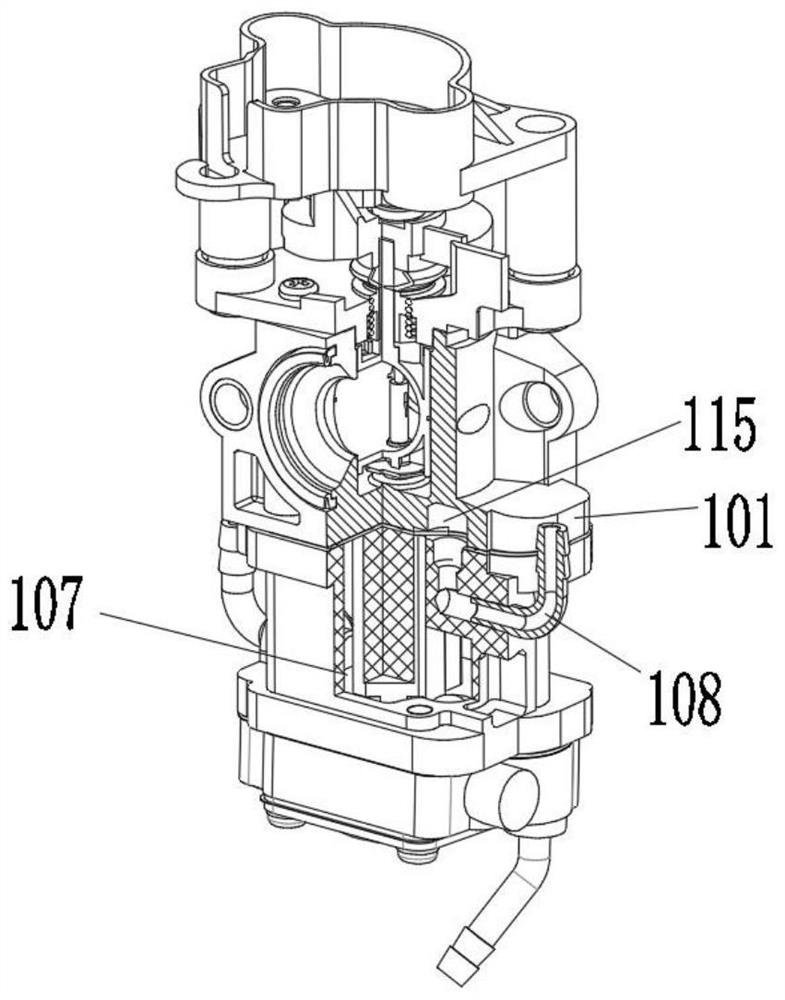

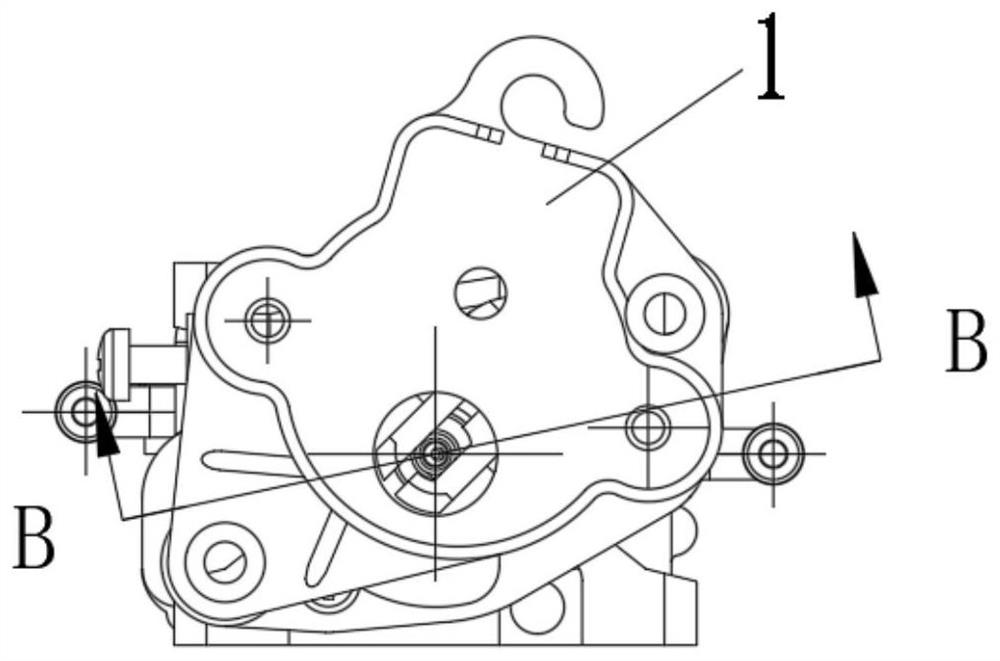

[0029] combine Figure 1~6 As shown, it schematically shows a diaphragm carburetor suitable for high-temperature conditions according to an embodiment of the present invention, including a main body 1, a diaphragm pump 2 and a metering system 3. It should be noted that in this embodiment Diaphragm pump 2 and metering system 3 all adopt the diaphragm pump 2 and metering system 3 of the existing carburetor. This embodiment does not involve improving the structure of diaphragm pump 2 and metering system 3. The main body 1 includes sequentially Connected upper body 101, heat insulating body 102, middle body 103 and lower body 104, upper body 101, heat insulating body 102, middle body 103 and lower body 104 are fixed together by screws to form a whole, diaphragm pump 2 and metering system 3. The generated fuel supply is sprayed from the main nozzle 110 through a fuel channel 109 to supply fuel to the carburetor main body 1. The upper body 101 is provided with a mixing chamber 106 c...

Embodiment 2

[0037] refer to Figure 7 ~ Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the lower end of the lower cover 302 is provided with a pump oil ball 4, and the pump oil ball 4 is connected to an oil pot through an oil circuit, and a The second one-way valve 116, the second one-way valve 116 opens and closes towards the balance pipe 108, and the function of the pump oil ball 4 is: when the engine is started, first squeeze the pump oil ball 4 by hand, because the pump oil ball 4 When squeezed, it deforms to generate vacuum suction, which sucks the fuel out of the oil pot, and the fuel from the Figure 10 The oil inlet pipe 111 in a (or b) enters, passes through the metering chamber 301 of the oil passage 1 to c, d, and e, and then passes through the oil pump ball 4 from f to g along the oil passage 2, and finally the fuel oil flows from g Return to the oil pot in the oil return pipe. After the above process, the process of sucking the fuel from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com