Adjustable steel pipe clamping mechanisms and vertical and horizontal mixed type steel pipe welding device

A clamping mechanism and welding device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult butt joint of B section, device cannot be welded vertically, safety accidents, etc., so as to improve welding efficiency and realize accurate welding. The effect of docking and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

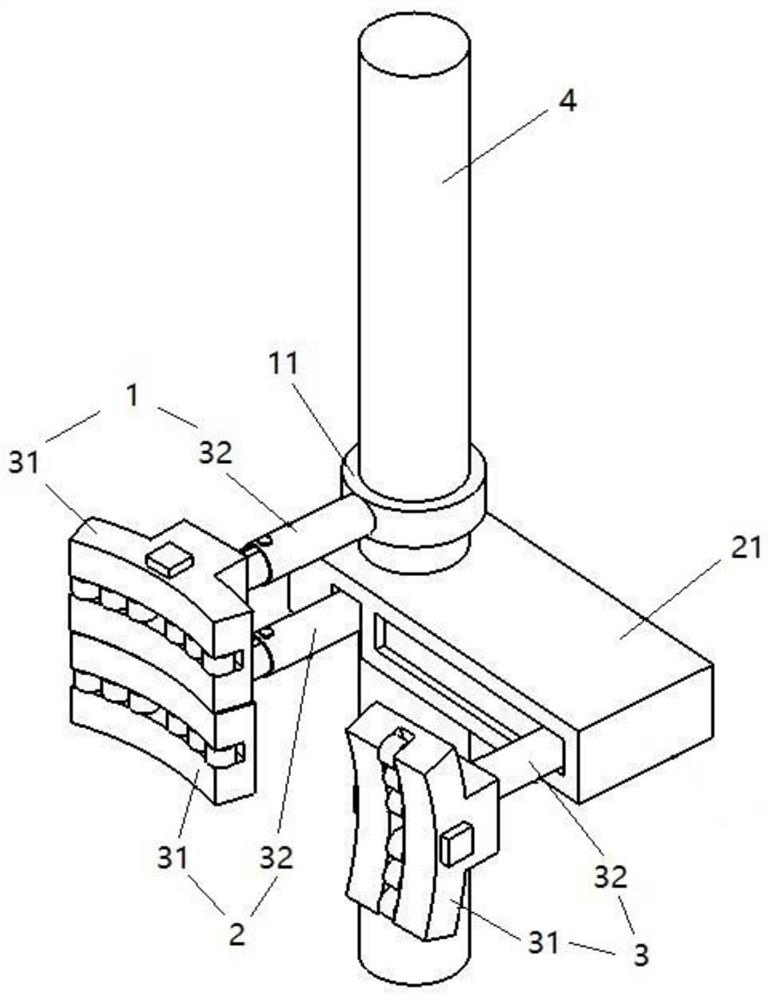

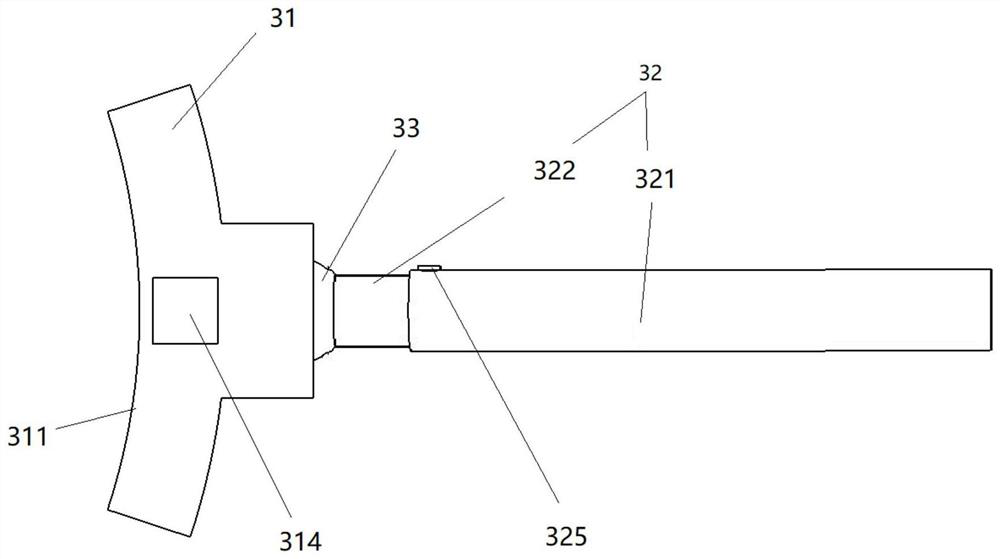

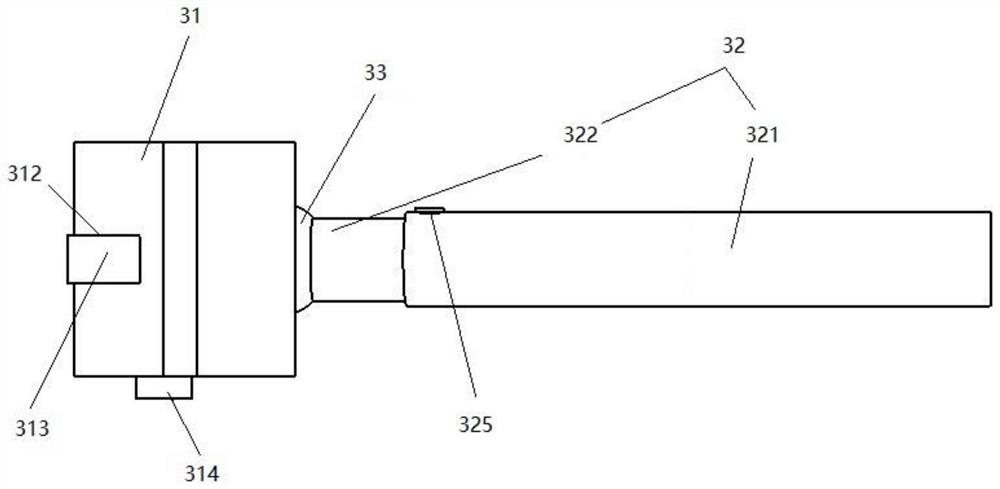

[0044] An adjustable steel pipe clamping mechanism, such as Figure 1-Figure 11 As shown, the column 4, the first clamping component 1, the square sleeve 21, the second clamping component 2 and the third clamping component 3; the first clamping component 1 is movably arranged on the column 4 through the sleeve 11 , the first clamping assembly 1 includes a clamping claw 31 and a telescopic rod 32, the side of the clamping claw 31 that cooperates with the surface of the clamped steel pipe is provided with a driving wheel 313, and the rotation direction of the driving wheel 313 is along the Rotating horizontally with the surface of the steel pipe, the telescopic rod 32 includes a fixed section 321 and a telescopic section 322 movably connected with the fixed section 321, one end of the telescopic section 322 is connected with the clamping claw 31, and the fixed section 321 One end is connected to the sleeve 11; the square sleeve 21 is movably sleeved on the column 4, and the squa...

Embodiment 2

[0056] A vertical and horizontal hybrid steel pipe welding device, comprising multiple adjustable steel pipe clamping mechanisms 8, a base 5, a vertical rod 601 and a welding gun 6 described in Embodiment 1, the base 5 is provided with a steel pipe installation port 501 A plurality of adjustable steel pipe clamping mechanisms 8 are movably arranged around the base 5, and a plurality of adjustable steel pipe clamping mechanisms 8 can connect two sections of steel pipes arranged vertically and two sections of steel pipes arranged horizontally; The pole 601 is movably arranged on the base 5 ; the welding gun 6 is arranged on the pole 601 .

[0057] The welding device in this embodiment can simultaneously realize vertical welding and horizontal welding of steel pipes in the welding process by switching the adjustable steel pipe clamping mechanism 8, and realizes the rapid adjustment of the welding method according to the actual size of the steel pipe to be welded during the working...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap