A kind of release heat-sealing packaging paper and its production method

A production method and wrapping paper technology, applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve the disadvantages of moisture-proof and dust-proof protection of the contents, the wrapping paper cannot realize heat-sealing and adhesion sealing, and the anti-adhesive layer cannot be butt jointed with heat-sealing adhesion and sealing And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

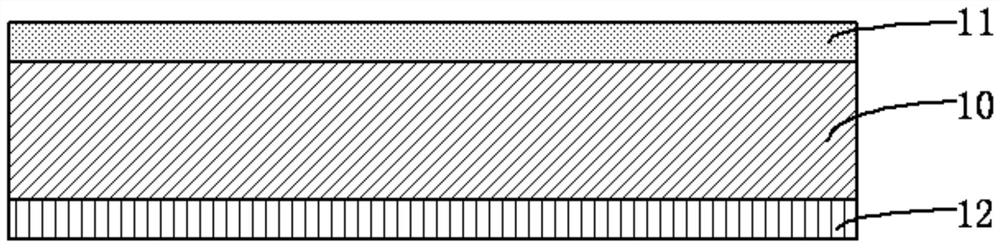

[0049] see figure 1 , a schematic view of the cross-sectional structure of the release heat-sealing wrapping paper of Example 1.

[0050] The main body of the release heat-sealing wrapping paper is a paper base material 10 . In this embodiment, the gram weight of the paper substrate 10 is about 30 g / m 2 .

[0051] The entire outer surface of the paper substrate 10 is covered with a layer of heat sealing layer 11 , and the entire surface of the inner surface (the inner surface facing the content) is covered with a layer of release heat sealing layer 12 .

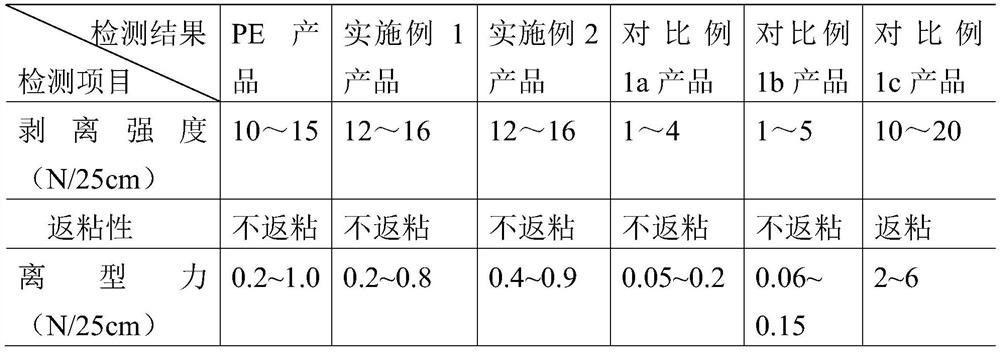

[0052] The release heat seal layer 12 is formed by coating with a water-based coating materialized by release heat press. Among them, the formulation of the water-based coating that is plasticized by release heat compression includes 93% thermoplastic water-based acrylic emulsion and 6% water-based polyethylene wax emulsion, and the solid content of the thermoplastic water-based acrylic emulsion is about 40-45%, and the wa...

Embodiment 2

[0064] The release heat-sealing wrapping paper of Example 2 is different from Example 1 in that: 1) The gram weight of the paper base material 10 of Example 2 is 60 g / m 2 2) The formulations of the water-based paints that are used in the release heat-sealing layer 12 of Example 2 are different. Specifically, the formula of the water-based paints that are released by hot-compression and plasticization comprises 86% thermoplastic water-based paints. Acrylic emulsion and 13% water-based polyethylene wax emulsion, and the solid content of thermoplastic water-based acrylic emulsion is about 42-45%; the solid content of water-based polyethylene wax emulsion is about 42%. In this embodiment, the thermoplastic water-based acrylic emulsion is a product of the model BT-62 purchased from DSM; the water-based polyethylene wax emulsion is a product of the model E-842N purchased from Wengkel Company.

[0065] The preparation method of the release heat-sealing wrapping paper of embodiment 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com