Protection and control method of DC charging pile residual pressure discharge resistor

A technology of DC charging piles and bleeder resistors, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of large impact heat energy of resistance, high instantaneous heat generation, large rated power space, etc., and achieve protection service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For a more clear representation of the present invention, the accompanying drawings The present invention will be further described in conjunction.

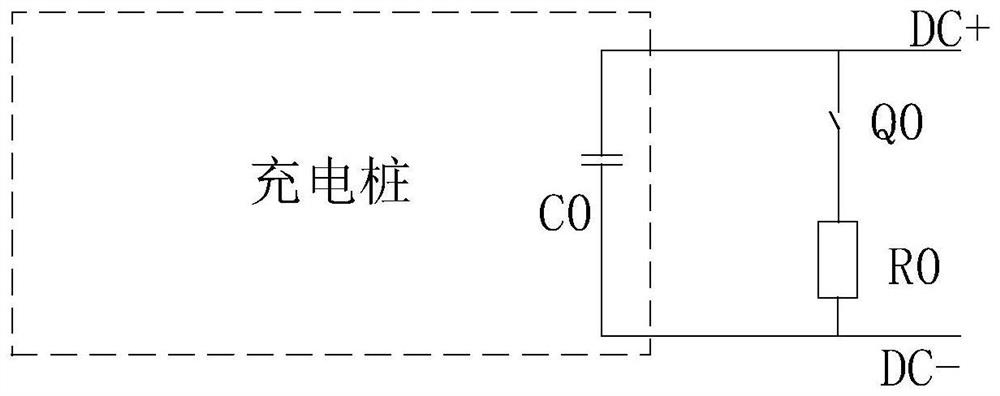

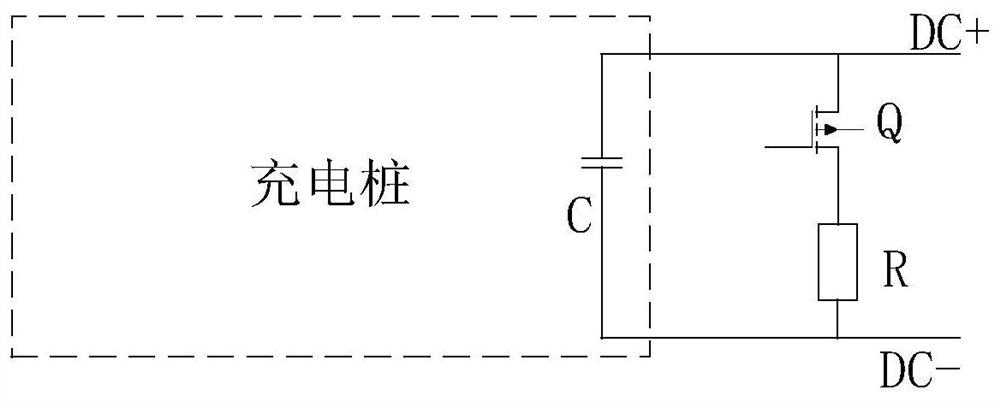

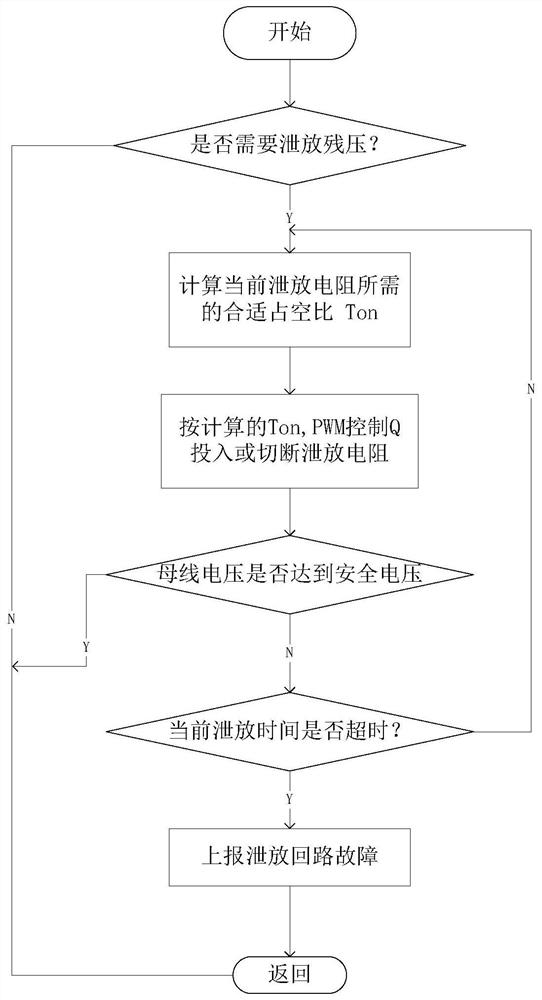

[0035] See figure 2 , Present invention provides a method for controlling the DC resistance and charging protection pile residual pressure relief, when the DC charging pile stops charging service, the high pressure discharge resistor R through the MOS transistor Q access bleeder circuit, based on the total bleeder resistor R subjected to heat shock initial maximum pulse power, the output voltage of capacitor C bus resistance can withstand, bleeder resistor R and the accumulated heat radiation coefficient constraints, the calculation of the cycle time, the maximum discharge resistor R by conducting time and then adjusted by the PWM control by the MCU voltage MOS transistor Q closing time, thus ensuring the bleeder resistor when the bus capacitor C bleed energy does not exceed the maximum amount of heat which can withstand the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com