Direct-current compressor

A technology of DC compressors and compressor casings, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problem of poor oil storage capacity of crankshaft climbing, easy wear and lock of the frame, and damage to the internal structure. and other problems to achieve the effect of reducing wear and locking, reducing impact noise and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

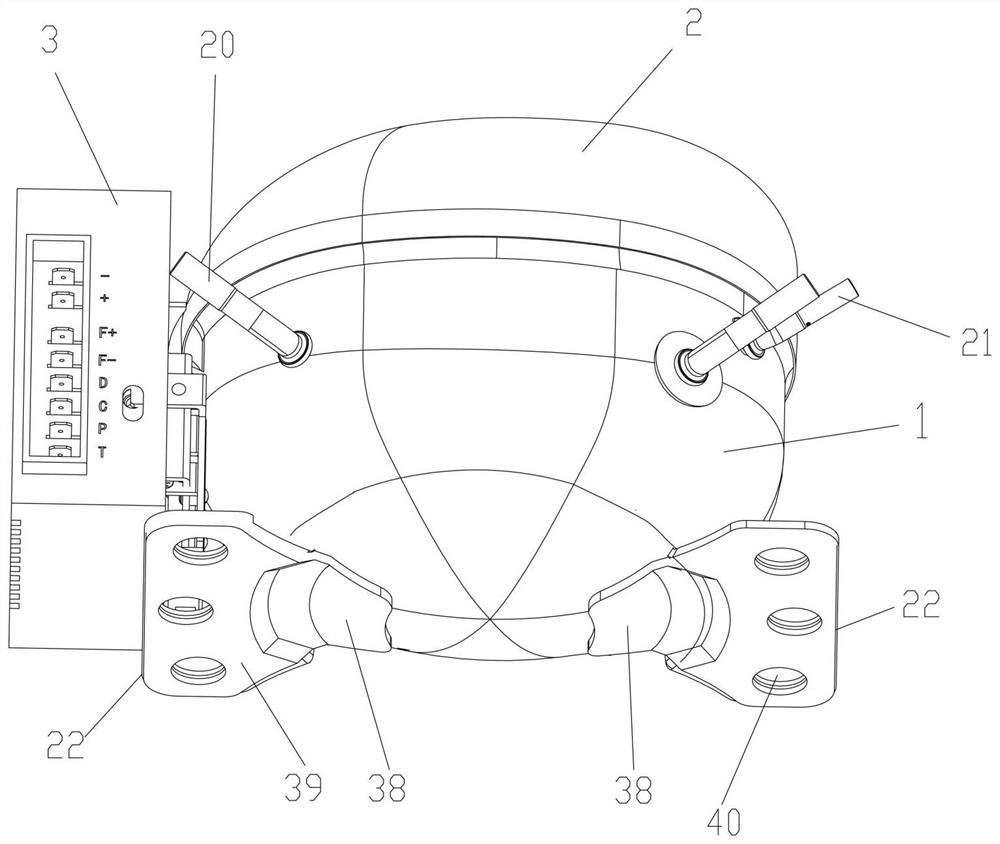

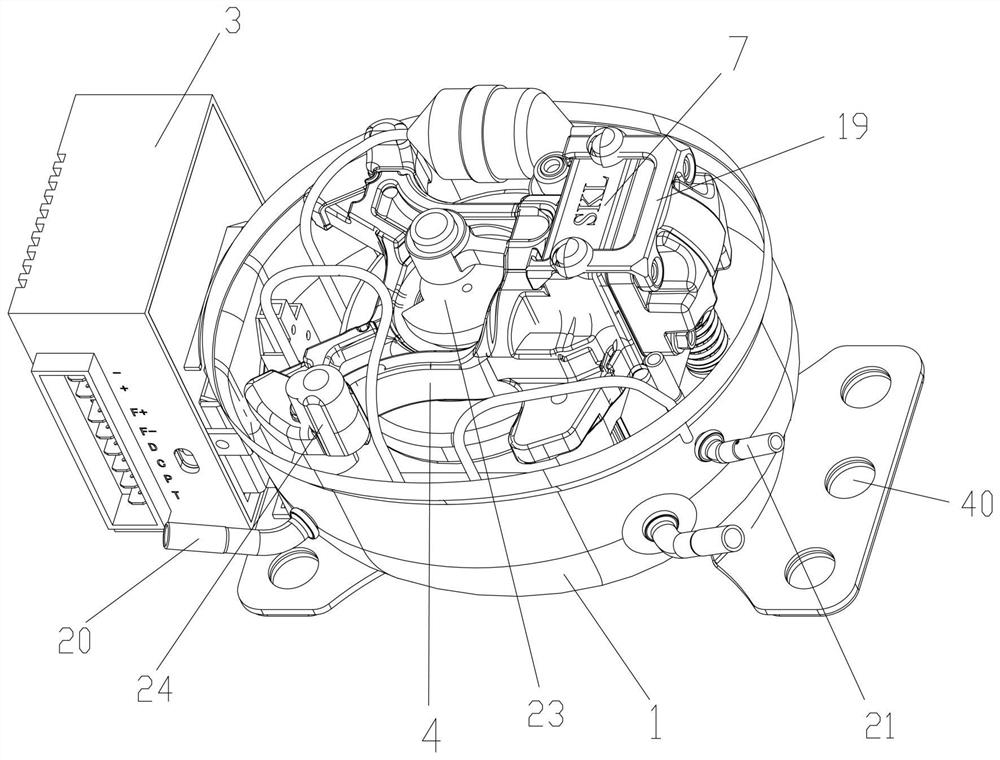

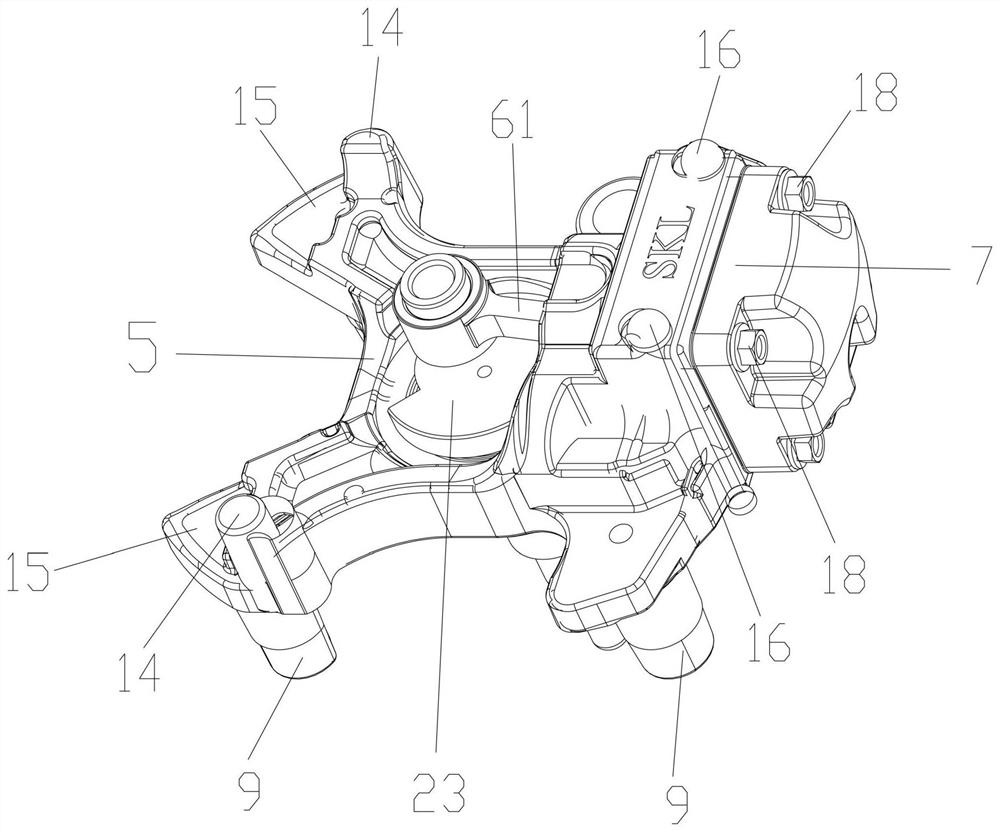

[0035] Example: A DC compressor, such as Figure 1-Figure 18 As shown, a compressor housing is included. A housing top cover is provided on the upper side of the compressor housing. The compressor housing and the housing top cover are combined into an oval shape. The left side of the compressor housing An electrical terminal box is provided on the side, and a frame assembly is provided in the compressor housing. The frame assembly includes a frame, a gas transmission S tube and a pressure pumping mechanism. The pumping pressure mechanism is located on the right side of the frame. Side, the middle of the frame is provided with a crankshaft hole, the lower sides of the four corners of the frame are provided with frame feet, and the lower side of the frame feet is provided with a stabilizing spring, which is between the stabilizing spring and the frame bracket A spring fixing bolt is arranged between the stabilizing spring, and the lower end of the stabilizing spring is provided w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap