Full-lining ceramic wheel valve

A ceramic and wheel valve technology, applied in the field of ceramic valves, can solve the problems of difficulty in meeting, easy to accumulate, valve power is not enough, etc., to achieve the effect of reliable sealing, easy to accumulate, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

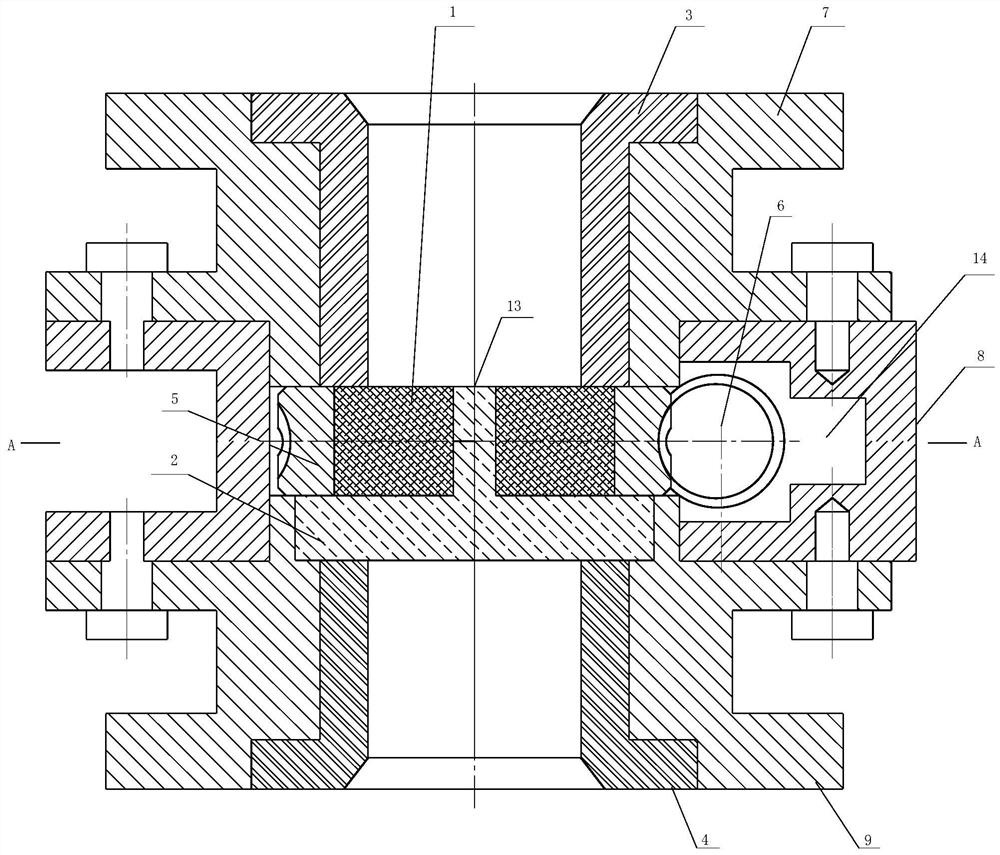

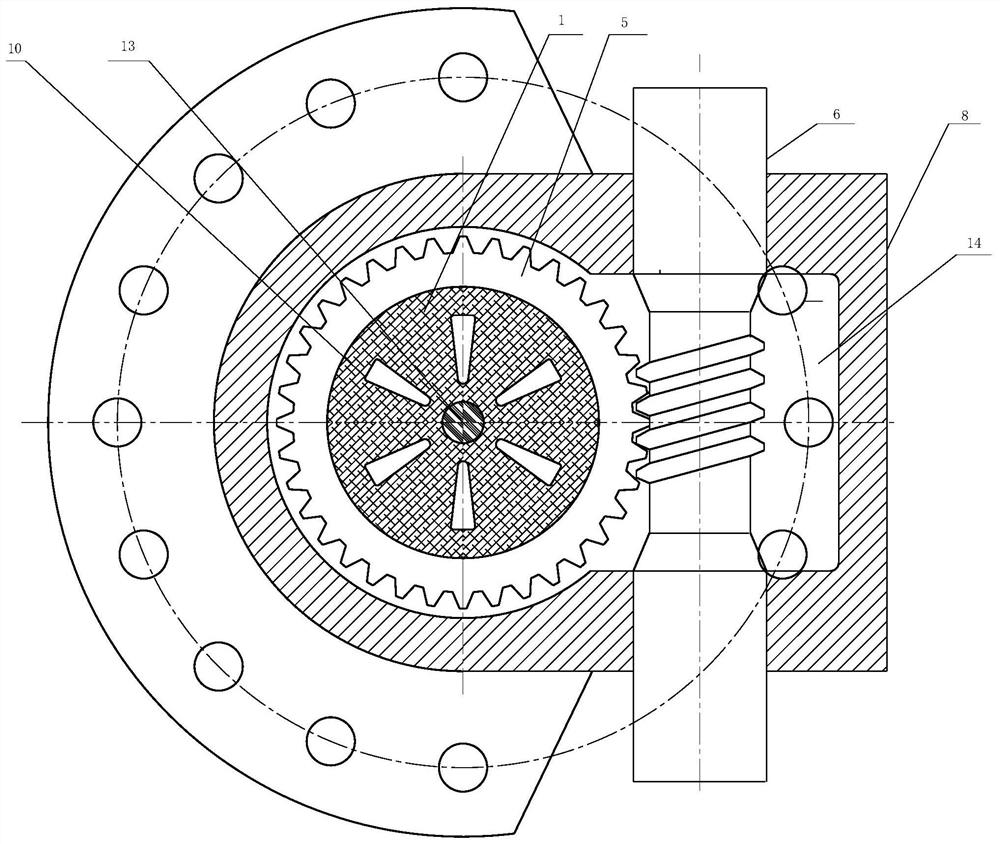

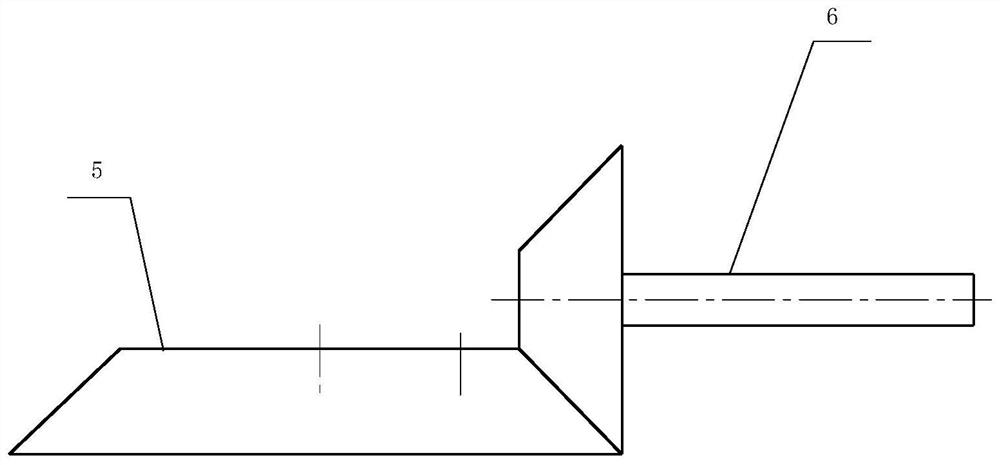

[0022] Such as figure 1 As shown, the fully lined ceramic wheel valve of the present invention includes: valve core 1, valve seat 2, upper flange lining 3, lower flange lining 4, drive ring 5, valve stem 6, upper flange 7, valve body 8 and The lower flange 9, the upper flange 7 and the lower flange 9 are respectively fixed on the upper end and the lower end of the valve body 8 by connecting pieces. The center lines of the upper flange 7, the lower flange 9 and the valve body 8 are on the same straight line. Upper flange 7 is equipped with upper flange lining 3, lower flange 9 is equipped with lower flange lining 4, and valve core 1 is installed in valve cavity 14 composed of upper flange lining 3, lower flange lining 4 and valve body 8. , Valve seat 2, drive ring 5 and valve stem 6. The valve seat 2 is fixed in the lower flange 9 and mounted on the lower flange liner 4. The center of the valve seat 2 has a raised shaft 13, and the valve core 1 is fixed on the drive ring 5. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap